Rhodium nanometer catalyst as well as preparation method and application thereof

A nano-catalyst and nano-flower technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, hydrogenation hydrocarbon production, etc., can solve problems such as the difficulty of adsorbing species, reducing the effective active sites on the surface, etc., and achieve less catalyst consumption, Superior catalytic activity, fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

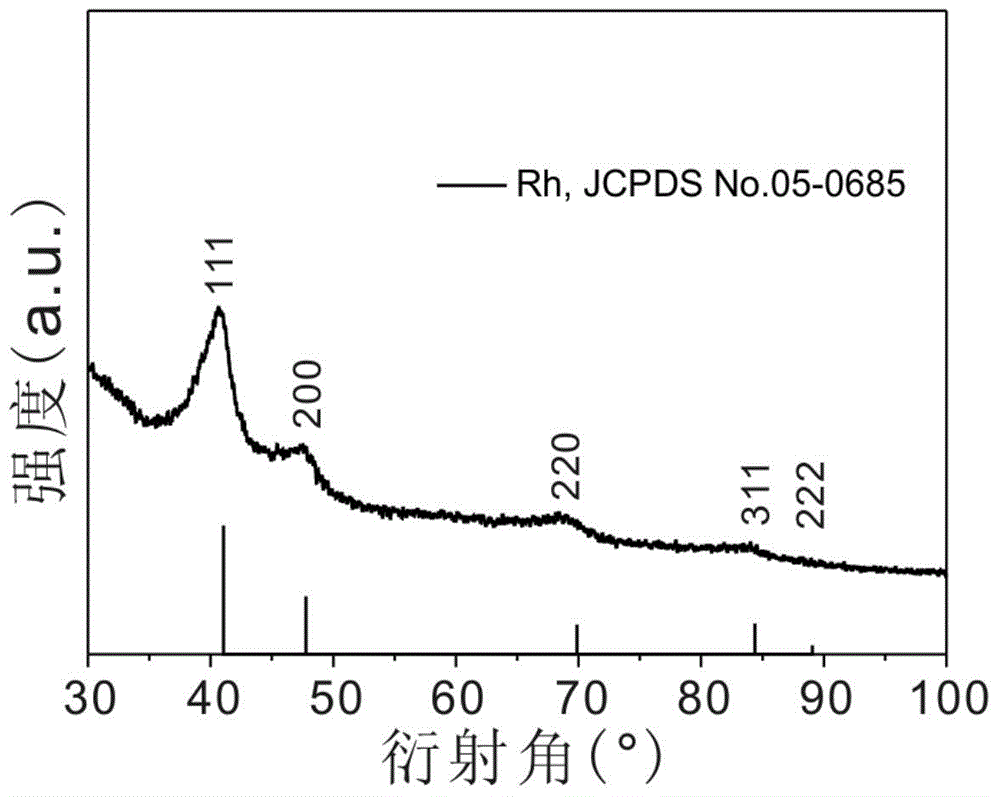

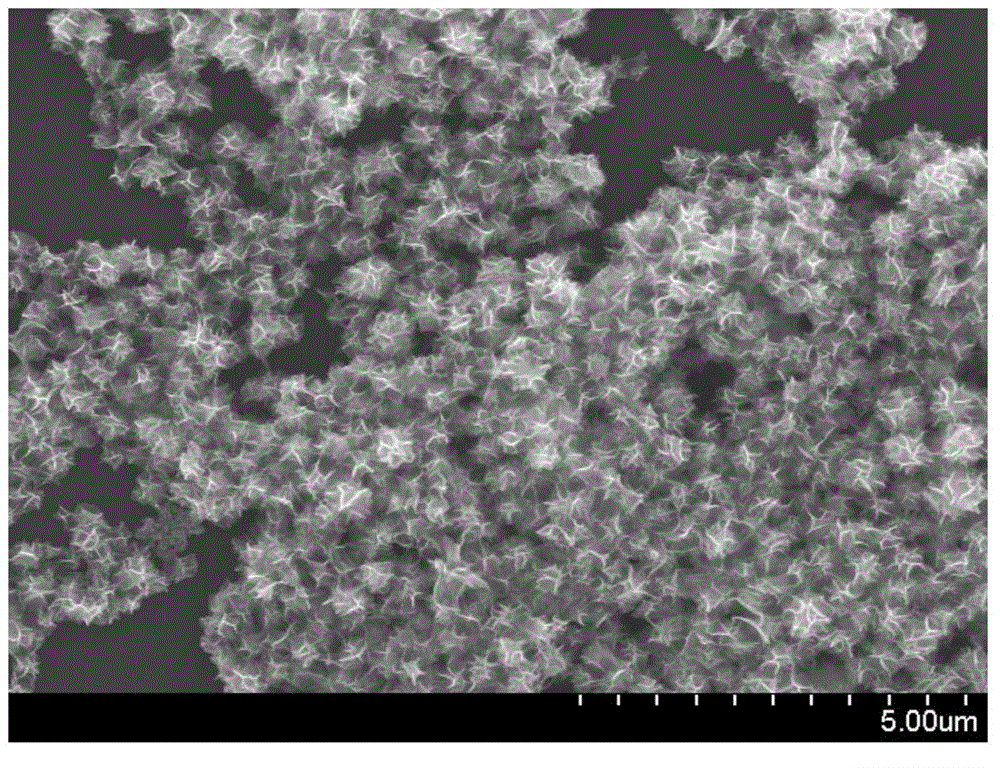

[0025] Weigh 0.025 mmol of rhodium acetylacetonate and place it in a polytetrafluoroethylene reactor, add 8 mL of deionized water, add 10 mmol of formaldehyde solution to the suspension, and stir magnetically for 20 min. Sealed and heated to 180°C, kept at constant temperature for 7 hours, then cooled naturally to room temperature. The product was centrifuged from solution and dried in air. The obtained rhodium catalyst powder has a flower-like multi-level structure composed of nano-sheets, the flower shape is about 350 nm, and the thickness of the flower flakes is about 1.1 nm. Its phase analysis is pure rhodium, which belongs to the face-centered cubic structure, and X-ray powder diffraction XRD is as follows: figure 1 As shown, its morphology analysis SEM is as follows figure 2 shown.

Embodiment 2

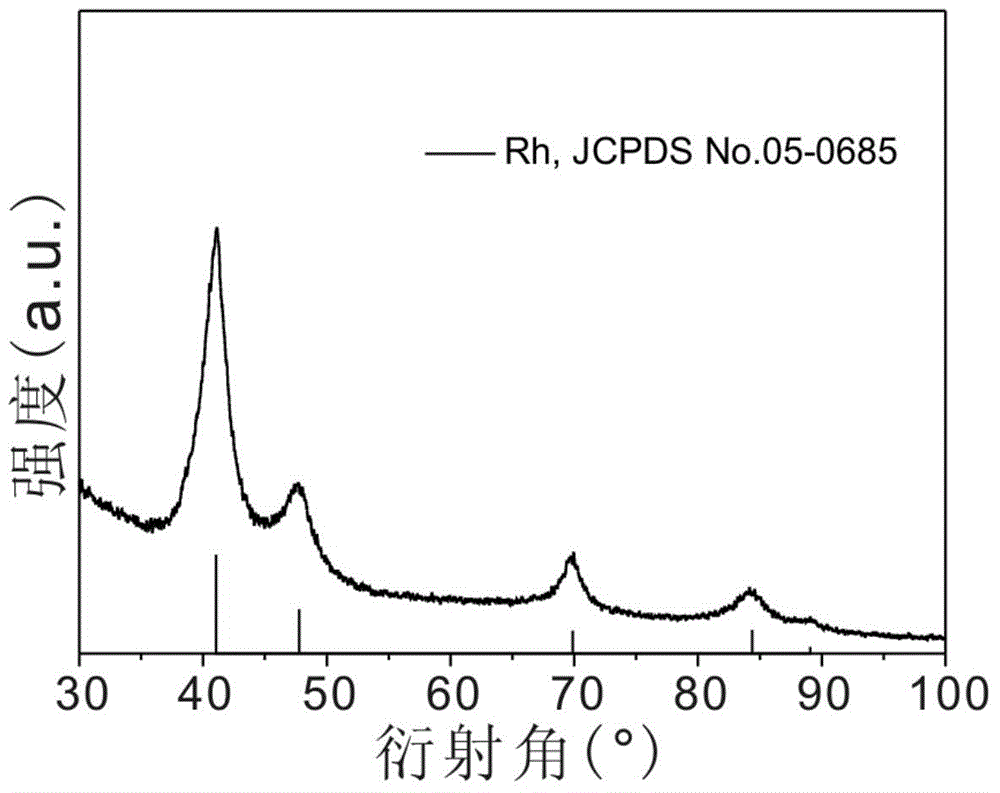

[0027] Weigh 0.025 mmol of rhodium acetylacetonate and place it in a polytetrafluoroethylene reactor, add 7 mL of deionized water, add 20 mmol of formaldehyde solution to the suspension, and stir magnetically for 20 min. Sealed and heated to 180°C, kept at constant temperature for 14 hours, then cooled naturally to room temperature. The product was centrifuged from solution and dried in air. The rhodium catalyst powder was obtained, the morphology was similar to that of Example 1, and the particle size of the nanoflowers was about 400nm. Its phase analysis result is identical with embodiment 1.

Embodiment 3

[0029] Weigh 0.025 mmol of rhodium acetylacetonate and place it in a polytetrafluoroethylene reactor, add 8 mL of deionized water, add 5 mmol of formaldehyde solution to the suspension, and stir magnetically for 20 min. Sealed and heated to 160°C, kept at constant temperature for 7 hours and then cooled to room temperature naturally. The product is centrifugally separated from the solution and dried in the air to obtain a rhodium catalyst powder. The morphology remains as a flower-like multi-level structure composed of nanosheets. The nanoflower particles are slightly smaller than in Example 1, and some nanosheets have small particles. Adhesion. Its phase analysis result is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com