Patents

Literature

71results about How to "Easy to wash and separate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

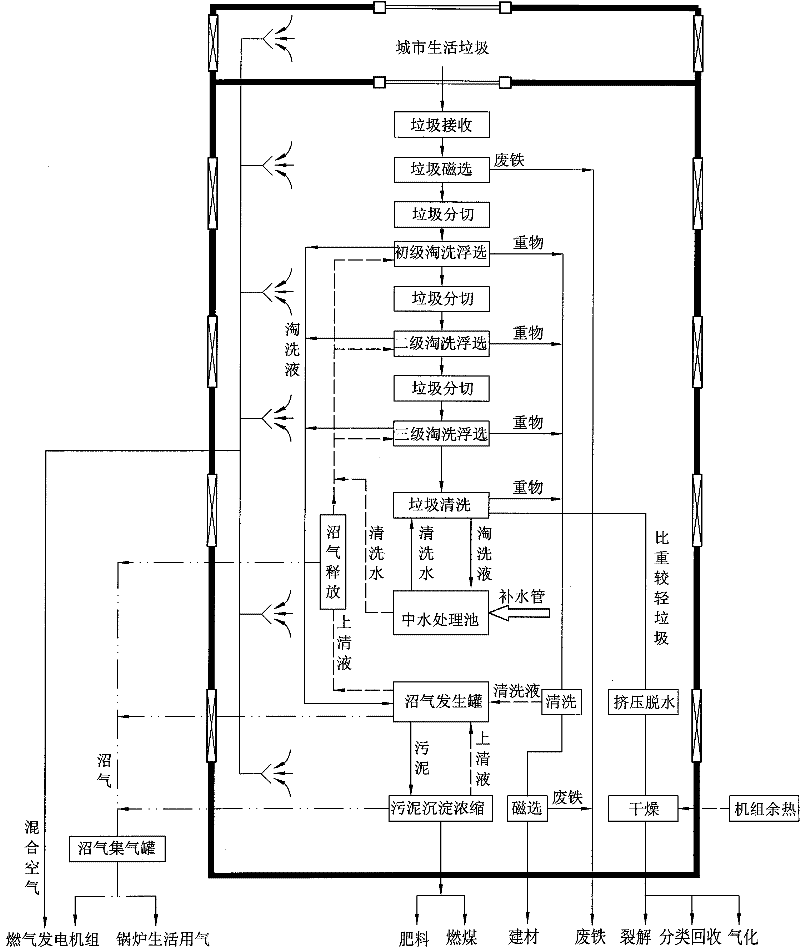

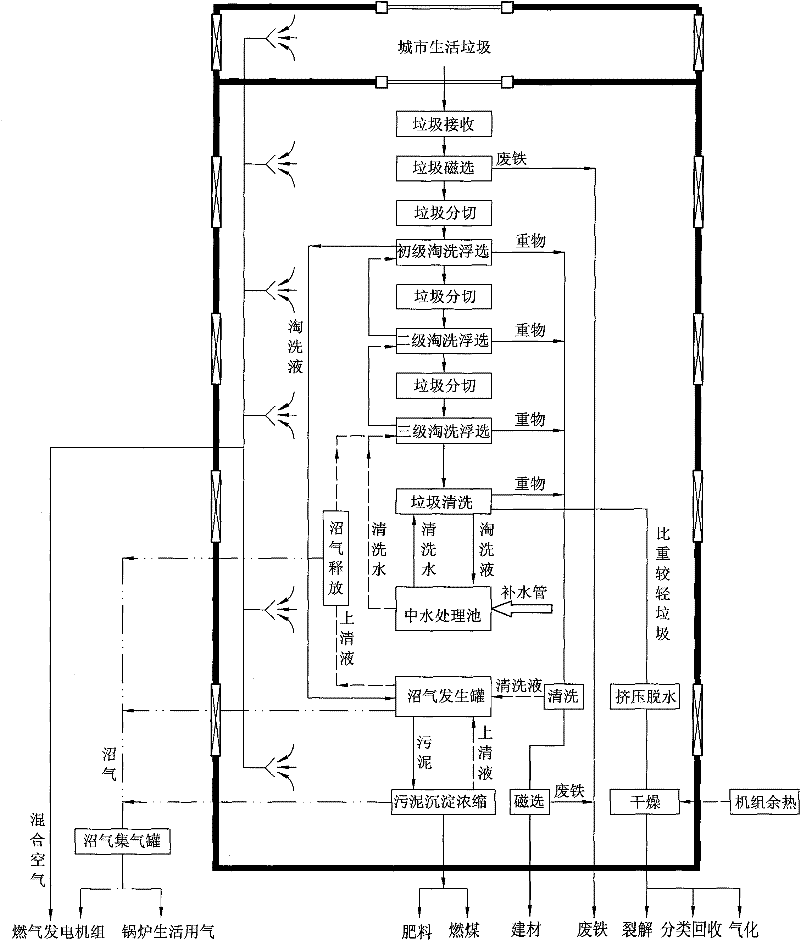

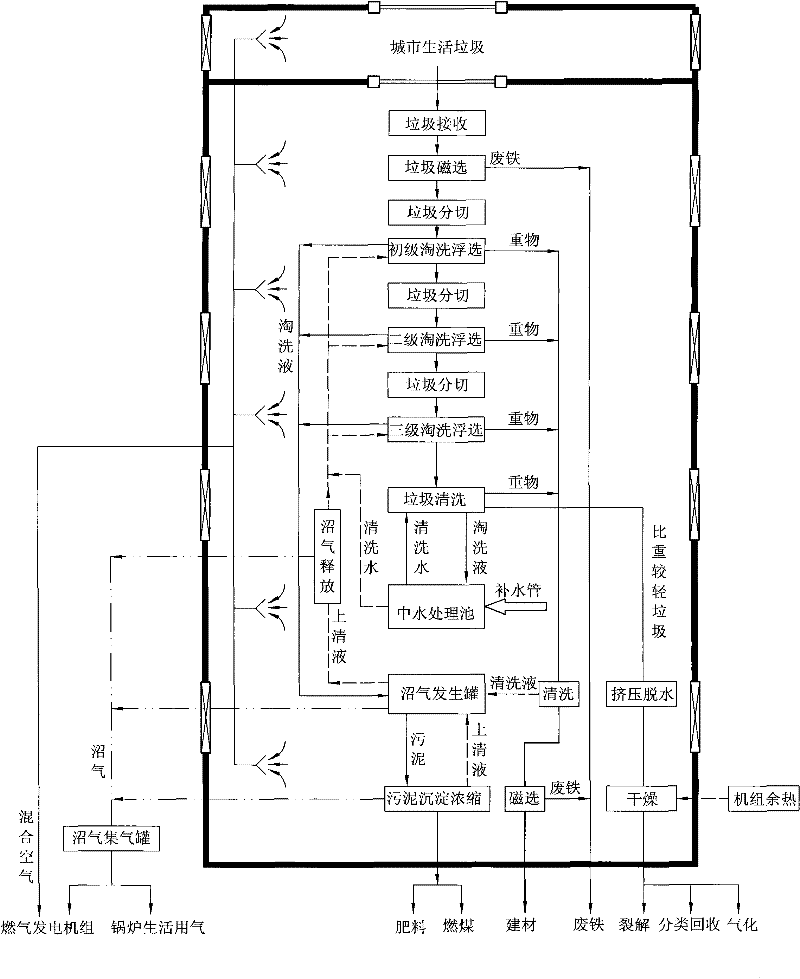

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

Catalyst for ternary polymerization of norbornene, maleic anhydride and pentene, and ternary polymerization method

InactiveCN103396514AHigh catalytic efficiencyEasy to wash and separateWater bathsReaction temperature

The invention relates to a catalyst for ternary polymerization of norbornene, maleic anhydride and pentene, and a ternary polymerization method. The catalyst is prepared by following steps: dissolving bis(cyclopentadienyl) zirconium dichloride, a ligand and an alkyl metal compound to a first solvent in a dry single-opening glass bottle in which inert gas is filled; sealing the bottle opening by an emulsion tube, keeping the bottle at a constant temperature for 5 to 15min in a water bath of 40 to 50 DEC C; and cooling so as to obtain the zirconium complex catalyst. Preparation method of the catalyst is simple. The catalyst can produce catalytic activity under a certain pressure, at a temperature and in nitrogen protection system; the norbornene, maleic anhydride and pentene are catalyzed and are subjected to ternary polymerization; and products are easy to wash and separate after being soaked by methanol. The yield of copolymer is high; the reaction temperature is low; the catalyst is low in cost and is easy to obtain; and the catalytic efficiency is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Catalyst for ternary polymerization of norbornene, derivative of norbornene, tetrafluoroethylene and cyclohexene and method of ternary polymerization

The invention relates to a catalyst for ternary polymerization of norbornene, a derivative of the norbornene, tetrafluoroethylene and cyclohexene and a method of the ternary polymerization. The preparation method of the catalyst comprises steps of dissolving ruthenium trichloride, ligand and an alkyl metal compound to a first solvent in a dry single-opening glass bottle in which inert gas is filled, sealing the bottle opening by using an emulsion tube, keeping the bottle at the constant temperature for 20-30 minutes in the water bath of 50 DEC C, cooling and obtaining a ruthenium complex catalyst. Compared with the prior art, the catalyst is the novel ruthenium complex catalyst, the catalyst can produce catalytic activity under certain pressure, at the temperature from 20 DEG C to 120 DEG C and in the nitrogen protection system, the norbornene, the tetrafluoroethylene and the cyclohexene are catalyzed and are subjected to the ternary polymerization, and products are easy to wash and separate after being soaked by methanol. The yield of copolymer is high, the reaction temperature is low, the catalyst is easy to obtain and the catalyst efficiency is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation of copolymer of norbornene and maleic anhydride

InactiveCN101328244AGood copolymerization performanceEasy to wash and separateMaleic anhydrideNorbornene

The invention relates to a method for preparing a norbornene and maleic anhydride copolymer. The method adopts a rare-earth complex as a catalyst to catalyze the alternating copolymerization of norbornene and maleic anhydride under normal pressure and at a temperature of between 4 and 100 DEG C; the reaction time is short, with only 5 to 9 hours required; the yield of copolymerization products is high and can reach over 67 percent; and the alternating degree of the copolymerization products is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, maleic anhydride and vinyl acetate ternary polymerization catalyst and ternary polymerization method

InactiveCN103626919AHigh catalytic efficiencyEasy to wash and separateReaction temperatureCarvacryl acetate

The invention relates to a catalyst for ternary polymerization of norbornene, maleic anhydride and vinyl acetate and a ternary polymerization method. The catalyst is characterized by being prepared by a method comprising the following steps: dissolving tri(cyclopentadienyl) neodymium, titanium tetrachloride and a ligand compound in a solvent in a dry single-opening glass bottle in an inert gas atmosphere, and sealing the opening of the bottle by using a latex tube, so as to obtain a titanium complex catalyst. Compared with the prior art, the invention provides a novel titanium complex catalyst and a ternary polymerization method using the same, the preparation method is simple, the titanium complex catalyst can generate catalytic activity in a nitrogen protection system at 40-90 DEG C to catalyze ternary polymerization of norbornene, maleic anhydride and vinyl acetate, and after being soaked in methanol, a polymerization product can be easily washed and separated; the catalyst has the characteristics of high yield, low reaction temperature, low price, availability, high catalytic efficiency and the like.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Catalyst for norbornene, maleic anhydride and acrylic ester ternary polymerization and preparation method of catalyst and ternary polymerization method

InactiveCN101691414AHigh catalytic efficiencyEasy to wash and separateNorborneneReaction temperature

The invention relates to a catalyst for norbornene, maleic anhydride and acrylic ester ternary polymerization and a preparation method of the catalyst and a ternary polymerization method; the catalyst is prepared by rare-earth complex and halogenated hydrocarbon and can generate catalytic activity in a nitrogen protection system at normal pressure and at the temperature of 0-150 DEG C for catalyzing norbornene, maleic anhydride and acrylic ester ternary polymerization, and the products are soaked by methanol for easy washing and separation; the invention has the characteristics of high copolymer yield, low reaction temperature, cheap and easy-obtaining catalyst and high catalyst efficiency.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, octafluorocyclopentene and cyclohexene ternary polymerization catalyst and ternary polymerization method

The invention relates to a norbornene, octafluorocyclopentene and cyclohexene ternary polymerization catalyst and a ternary polymerization method. The catalyst is characterized in that a preparation method for the catalyst comprises the following steps: rhodium(I) tris(triphenylphosphine) chloride, alkyl aluminium and a ligand ompound are dissolved in a first solvent in a single-mouth glass bottle with the dry inert atmosphere, the bottle mouth is sealed through a latex tube, and heat preservation is carried out for 20-30 minutes at 20-30 DEG C, so as to obtain a rhodium-aluminum complex catalyst, wherein the mole ratio of rhodium(I) tris(triphenylphosphine) chloride to the ligand is (1:8)-(8:1). The catalyst provided by the invention is a novel rhodium-aluminum complex catalyst mixture, raw materials of the catalyst are cheap and accessible, norbornene, octafluorocyclopentene and cyclohexene ternary polymerization can be catalyzed since catalytic activity can be generated at lower temperature, the reaction temperature is low, catalytic efficiency is high, the product is easy to wash and separate, and the yield of the copolymer is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

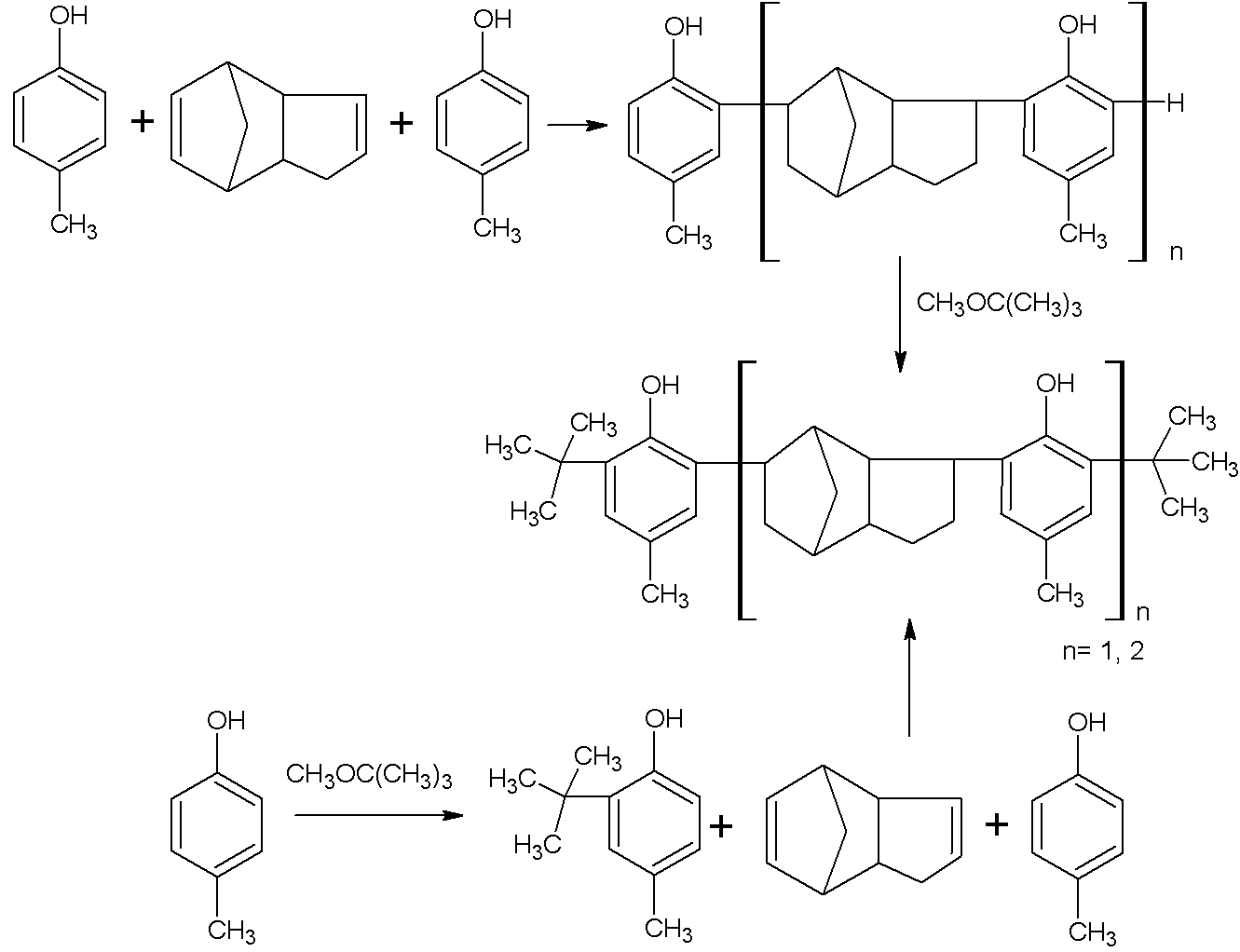

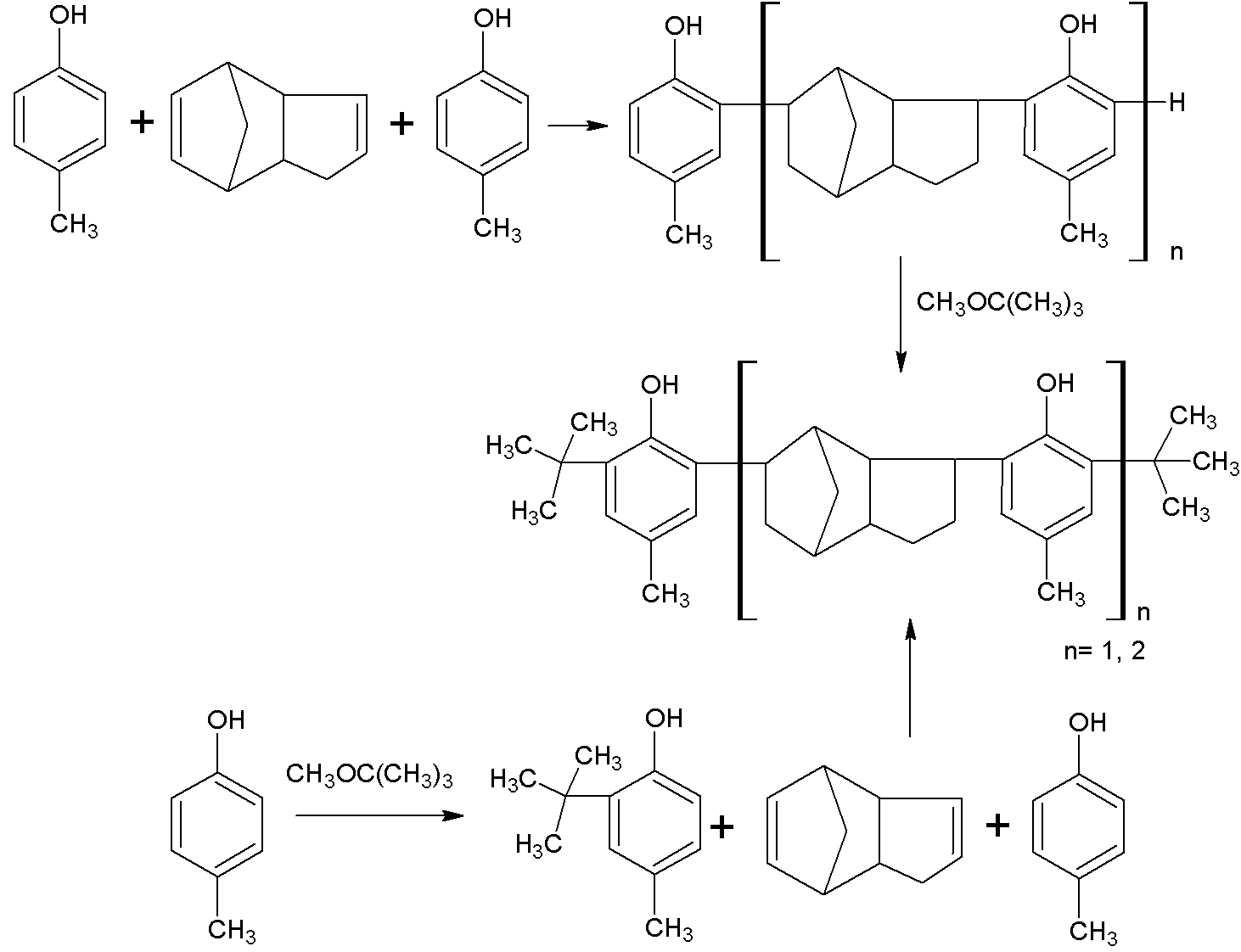

Method for producing aggregate-type hindered phenol antioxidant

InactiveCN103319315AReduce usageImprove efficiencyOrganic chemistryOrganic compound preparationSolubilityWater vapor

The invention provides a method for producing aggregate-type hindered phenol antioxidant. The method comprises the following steps of: firstly reacting p-cresol with dicyclopentadiene and a non-water-solubility solvent through an organic composite sulfonic acid catalyst under the anhydrous condition to obtain p-cresol-dicyclopentadiene resin; then adding tert-Butyl methyl ether so as to produce a p-cresol-dicyclopentadiene-isobutylated resin crude product, or firstly reacting the p-cresol with the tert-Butyl methyl ether and the non-water-solubility solvent through the organic composite sulfonic acid catalyst under the anhydrous condition to obtain an o-tert-butyl p-cresol; then adding the dicyclopentadiene so as to produce the p-cresol-dicyclopentadiene-isobutylated resin crude product; washing the crude product by water, and carrying out steam distillation on the crude product to obtain the aggregate-type hindered phenol antioxidant, wherein the final yield reaches more than 95%. The method has the advantages that the adopted organic composite sulfonic acid catalyst is low in cost, common and easy to wash by water and separate, water can be recycled, the product has good color and luster, low ash content and high purity, the treatment process is simple, equipment is free of being corroded, the technology is clean and environmentally-friendly, and the product yield reaches more than 95%.

Owner:HUBEI UNIV OF TECH

Norbornene, hexafluoropropylene and acrylonitrile ternary polymerization catalyst and ternary polymerization method

ActiveCN105693928AHigh yieldImprove corrosion resistancePentamethylcyclopentadieneHexafluoropropylene

The invention relates to a norbornene, hexafluoropropylene and acrylonitrile ternary polymerization catalyst. The preparation method of the catalyst comprises the steps that (pentamethyl cyclopentadiene) cerium chloride and a ligand are dissolved into a first solvent in a dry three-mouth flask in the inertia atmosphere, titanium tetrachloride is dropped into the solution while stirring is performed, stirring is performed at the constant temperature of 30-60 DEG C for 30-60 min after dropping is performed, and a cerium-titanium complex catalyst is obtained. The polymerization method comprises the steps that a norbornene monomer, a hexafluoropropylene monomer and an acrylonitrile monomer are taken and added into a reaction kettle where repeated vacuumizing and nitrogen charging are performed, and a second solvent is added for dissolution; then, the cerium-titanium complex catalyst is added, a reaction is performed under the certain temperature and pressure, and the product is washed to obtain the terpolymer. Catalyst raw materials are low in price and easy to obtain, catalytic activity can be generated at low temperature, norbornene, hexafluoropropylene and acrylonitrile ternary polymerization is catalyzed, the reaction temperature is low, the catalysis efficiency is high, the copolymer yield is high, and the terpolymer is good in photoetching performance.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Ternary polymerization catalyst of norbornene, octafluorocyclopentene and styrene and ternary polymerization method

The invention relates to a ternary polymerization catalyst of norbornene, octafluorocyclopentene and styrene and a ternary polymerization method, wherein the catalyst is prepared through a following method comprising steps of: 1) dissolving neodymium trichloride, diethyl zinc and a ligand compound in a first solvent in a dried single-mouth glass bottle under an inert gas atmosphere; 2) sealing the mouth of the bottle by a latex pipe, performing a reaction at a constant temperature of 40-60 DEG C for 20-30 min to prepare a neodymium / zinc complex catalyst; 3) according to a ratio of 1:1:1, adding a norbornene monomer, an octafluorocyclopentene monomer and a styrene monomer into a high-pressure kettle which is vacuumized for several times and is filled with nitrogen, and adding a second solvent to dissolve the raw materials; 4) adding the neodymium / zinc complex catalyst, and carrying out a reaction at 20-90 DEG C for 0.1-6 MPa for 1-6 h; and 5) washing a reaction product to obtain a terpolymer. The raw materials of the catalyst are low in cost and are easy to obtain. The catalyst can generate catalytic activity at a low temperature and is high in catalytic efficiency. A product is very easy to wash and separate and the method is high in yield of the co-polymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

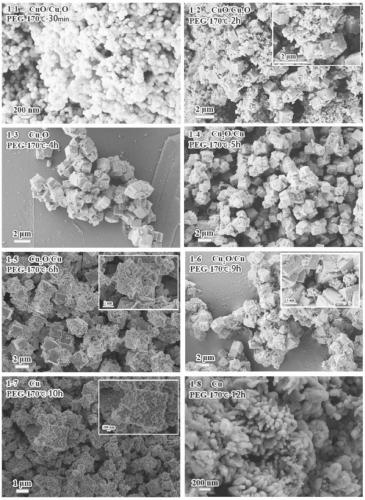

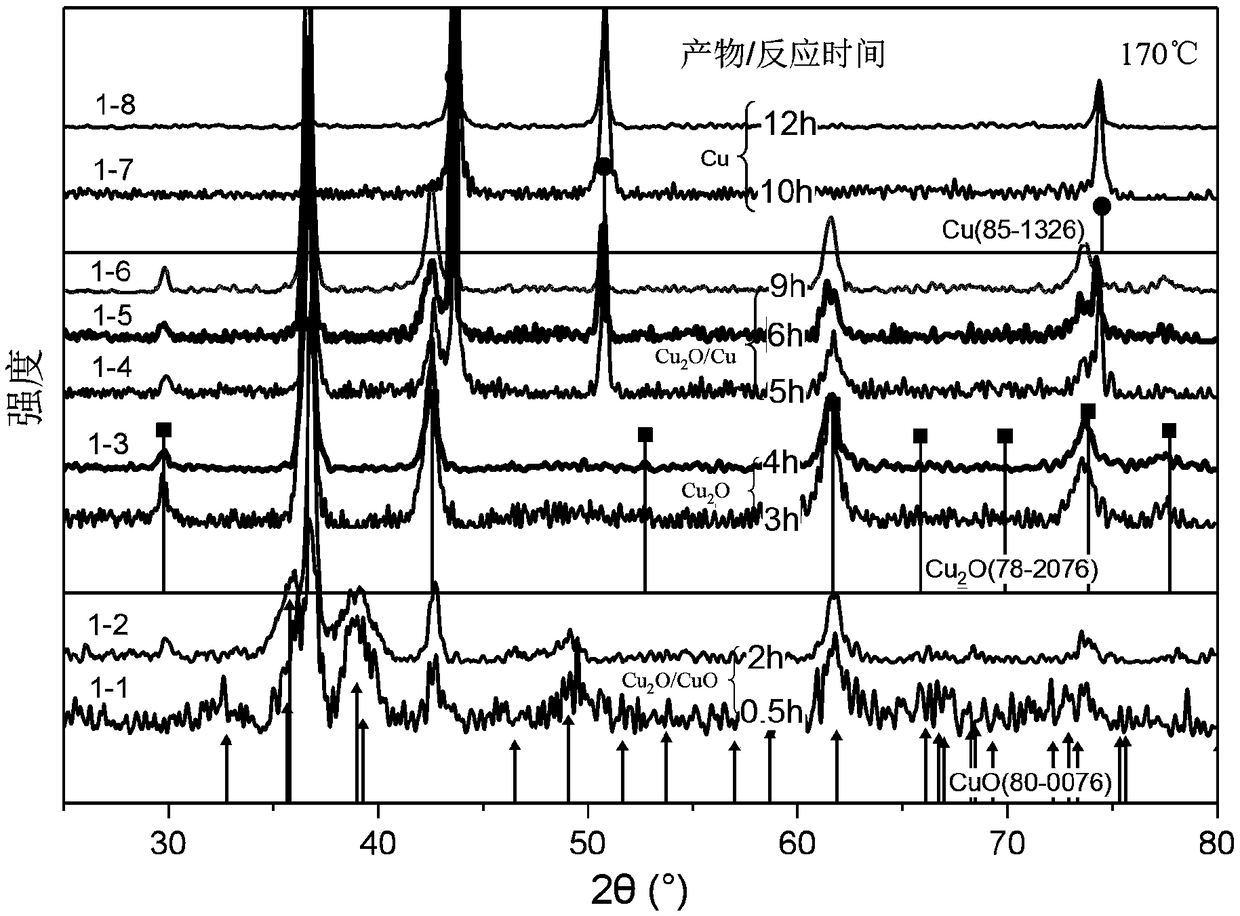

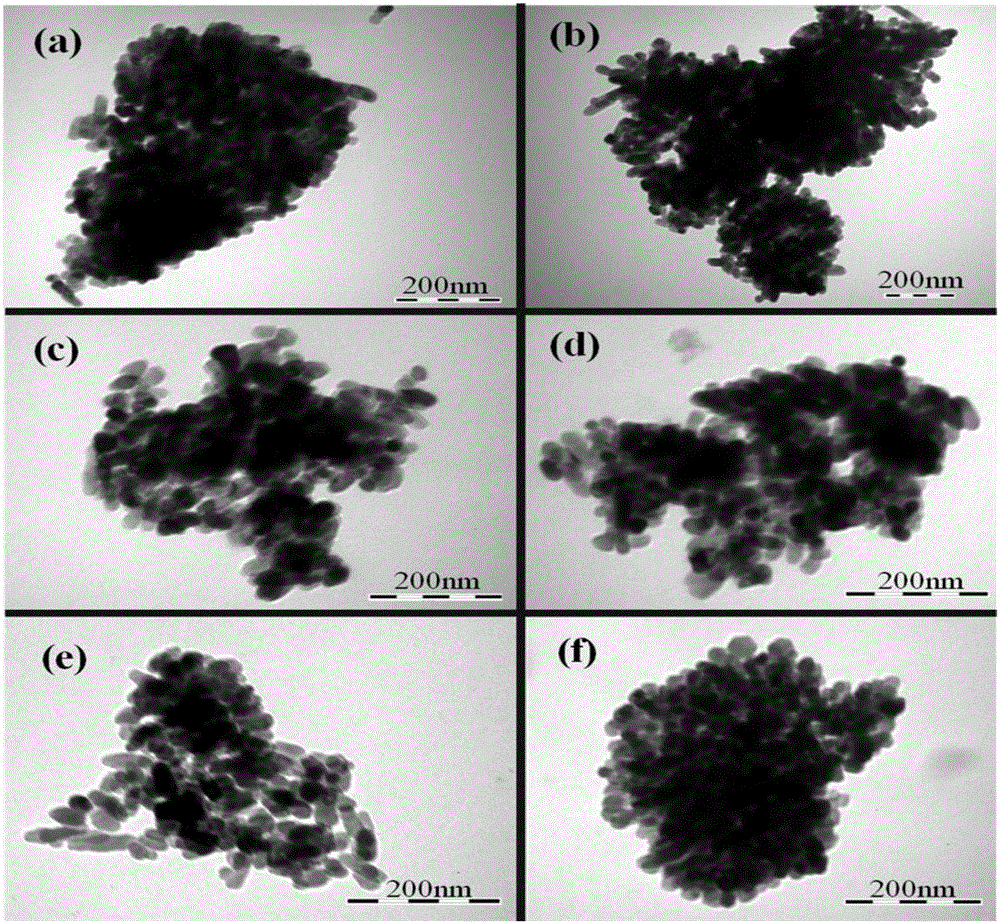

Copper based nanometer/micron composite particles as well as preparation method and application thereof

ActiveCN109110795AReduce consumptionHigh yieldMaterial nanotechnologyPhysical/chemical process catalystsOrganic synthesisPolyethylene glycol

The invention discloses copper based nanometer / micron composite particles as well as a preparation method and application thereof. The preparation method comprises the following steps of by taking polyethylene glycol as a green solvent, a modifier and a reducer and copper salts such as cupric acetate monohydrate as a raw material, adopting a one-step method to prepare copper based composite particles with good dispersion at different times and temperatures, and studying the photocatalytic performance of a product under visible light illumination. The preparation method provided by the invention is simple in used equipment and rich in raw material, can reduce the cost, provide experiment and theoretical basis to industrial development and application; and the prepared composite particles can rapidly degrade organic pollutants under visible light and have a wide application prospect in the field of photocatalysis, biomedicine and organic synthesis.

Owner:JINAN UNIVERSITY

Norbornene, hexafluoropropylene and 1-hexene ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, hexafluoropropylene and 1-hexene ternary copolymerization catalyst and a ternary copolymerization method. The catalyst is characterized in that a preparation method of the catalyst includes: in a dry single-opening glass bottle in an inert atmosphere, dissolving ferrocene, titanium tetrachloride and a ligand in a first solvent; using a latex tube to seal the opening of the bottle; maintaining constant temperature at 20-50 DEG C for 20-50 min to obtain an iron-titanium complex catalyst; the ternary copolymerization method includes: taking and adding norbornene, hexafluoropropylene and 1-hexene monomer according to a molar ratio of 1:1:1 into a high-pressure kettle vacuumized for many times and filled with nitrogen, and adding a second solvent for dissolution; adding the iron-titanium complex catalyst for reaction at 30-130 DEG C for 2-6 h. Raw materials of the catalyst are low in cost and easy to get, the catalyst can generate catalytic activity at low temperature and is low in reaction temperature and high in catalytic efficiency, and a product can be washed and separated quite easily and high in copolymer yield.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Ternary polymerization catalyst and ternary polymerization method for norbornylene, vinylacetate and octafluorocyclopentene

InactiveCN104262513ALow reaction temperatureEasy to wash and separateReaction temperatureCarvacryl acetate

The invention relates to a ternary polymerization catalyst and a ternary polymerization method for norbornylene, vinylacetate and octafluorocyclopentene. The ternary polymerization catalyst is prepared by steps as follows: tris(cyclopentadienyl)praseodymium, bis(triphenylphosphine)nickel(II)chloride, a ligand and a first solvent are placed in a dry single-ported glass bottle filled with inert gas, a bottle mouth is sealed by a latex tube, the constant temperature in a range from 45 DEG C to 55 DEG C is kept for 25-35 min, and after dissolving, the ternary polymerization catalyst is obtained. Co-monomers are taken in proportion, the catalyst is added, and terpolymers are obtained through reaction at certain temperature and pressure. The provided catalyst can generate catalytic activity in a nitrogen production system at the temperature of 50 DEG C-150 DEG C and under the pressure of 0.1 MPa-6 MPa and catalyze ternary polymerization of norbornylene, vinylacetate and octafluorocyclopentene, and a polymerization product is very easy to wash and separate; the copolymer yield is high, the reaction temperature is low, raw materials of the catalyst are cheap and easy to obtain, and the catalytic efficiency is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene-cyclohexene-vinylene carbonate ternary copolymerization catalyst and ternary copolymerization method

The present invention relates to a norbornene-cyclohexene-vinylene carbonate ternary copolymerization catalyst. The preparation method comprises: in a three-necked flask in a dry inert gas atmosphere, dissolving tris(cyclopentadiene)gadolinium (III) and a ligand in a first solvent, adding titanium tetraisopropanolate in a dropwise manner under 300-500 rpm, and carrying out constant temperature stirring for 30-60 min at a temperature of 30-60 DEG C at the same stirring rate after adding the titanium tetraisopropanolate to obtain a gadolinium-titanium complex catalyst; taking a norbornene monomer, a cyclohexene monomer and a vinylene carbonate monomer according to a molar ratio of 1:1:1, adding to a reaction kettle being subjected to multiple vacuumizing and nitrogen filling, adding a second solvent, and dissolving; adding the gadolinium-titanium complex catalyst, and carrying out a reaction for 1-6 h at a temperature of 30-100 DEG C under a pressure of 0.1-6 MPa; and pouring the product obtained through the reaction into a hydrochloric acid-containing ethanol solution, washing the obtained precipitate by using ethanol to achieve a neutral state, and carrying out vacuum drying to obtain the norbornene-cyclohexene-vinylene carbonate ternary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

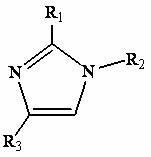

Production process of imidazole ionic liquid

InactiveCN102351796ASmall particlesReduce moisture contentOrganic chemistryWater bathsReaction temperature

The invention discloses a production process of imidazole ionic liquid and aims to provide an industrialized method for preparing imidazole ionic liquid. The technical scheme of the method comprises the following steps: adding an imidazole compound and halogenated hydrocarbon in a reaction kettle, wherein the molar ratio of the imidazole compound to halogenated hydrocarbon is 1:(2-5), refluxing and stirring, heating with a water bath, reacting at 20-60 DEG C for 6-48 hours, standing, recycling the excess raw material to obtaining a solid product, washing the solid product to purify, separating in a centrifugal machine and performing vacuum drying. The reaction process in the invention does not use the solvent; as the reactant halogenated hydrocarbon is excess, the product is dispersed to tiny particles, the subsequent washing purification operation is easy to perform and the product is convenient to extract and use; the excess reactant halogenated hydrocarbon can be recycled and distilled for recycling; the production process has low reaction temperature, short reaction time and less energy consumption; and the solid product of the reaction has small particles and is convenient to wash and separate.

Owner:LINZHOU KENENG MATERIAL TECH

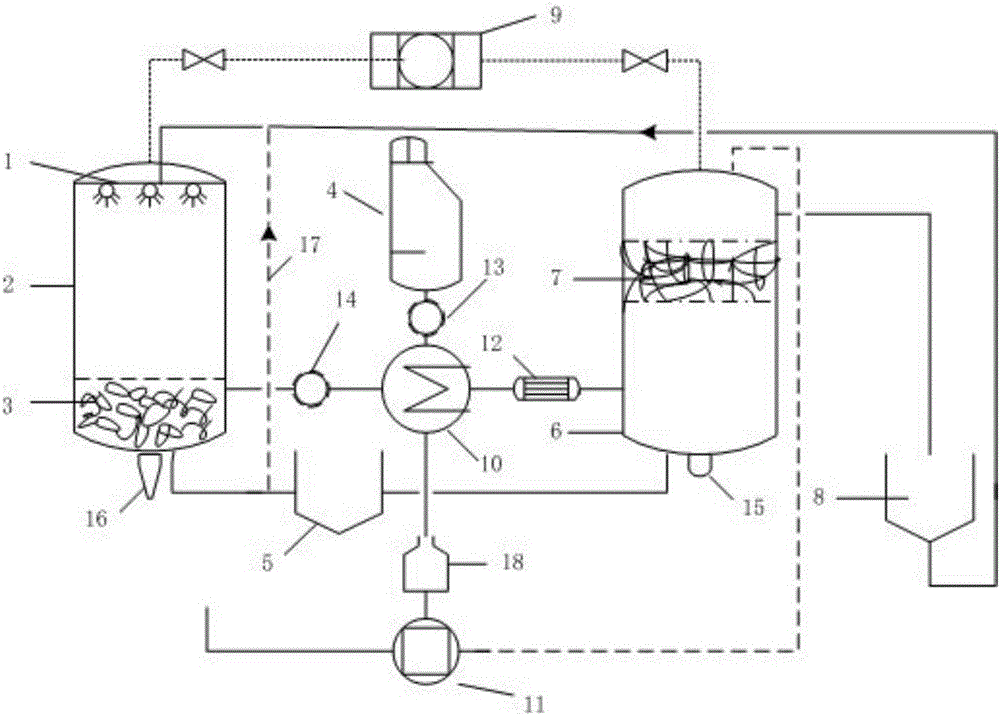

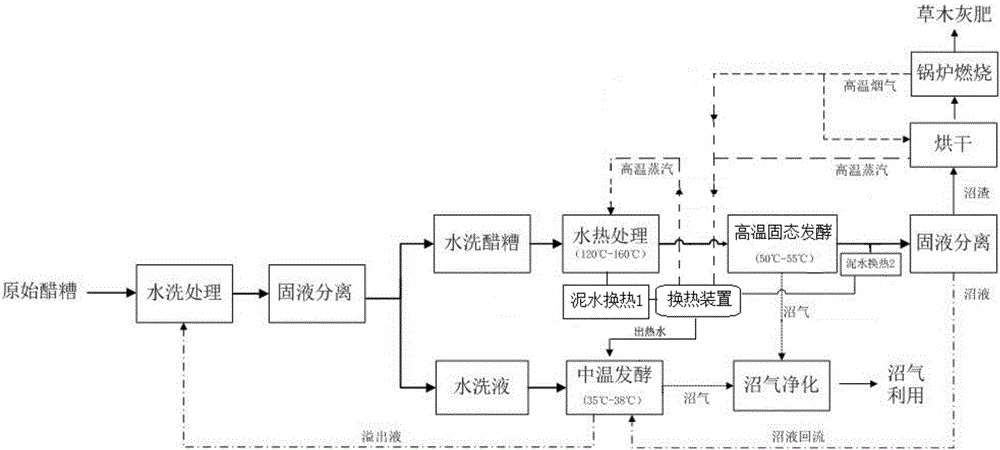

Device and method for producing marsh gas by vinegar residue solid and liquid split-phase anaerobic digestion

InactiveCN106754294AAchieve thermal cyclingRealize the water cycleBioreactor/fermenter combinationsBiological substance pretreatmentsOrganic acidWater storage tank

The invention relates to a device and a method for producing marsh gas by vinegar residue solid and liquid split-phase anaerobic digestion, and belongs to the technical field of biological fermenting. The device mainly comprises a solid-state fermenting tank, a high-temperature boiler, a filler reactor, a marsh gas purifier, a solid and liquid separator, and a water storage tank. The invention also discloses a method using the device to produce marsh gas by the vinegar residue solid and liquid split-phase anaerobic digestion. The method mainly comprises the following steps of (1) spraying and washing vinegar residue by water in the solid-state fermenting tank; (2) performing high-temperature hydrothermal treatment on the filtered water-washing vinegar residue; (3) performing medium-temperature vinegar residue fermentation on water washing liquid; (4) performing high-temperature solid-state fermentation; (5) purifying and utilizing the marsh gas. The device and the method have the characteristics that the vinegar residue solid and liquid split-phase anaerobic digestion is realized, the content of organic acid in the vinegar residue is high, the water washing and separation are easy, and the like; in the fermenting process, the adding of other raw materials is not needed, the hydrothermal circulation is realized, the cost is reduced, the traditional vinegar residue anaerobic digestion is broken, and the production capacity of marsh gas is increased.

Owner:CHANGZHOU UNIV

Norbornene, tetrafluoroethylene and N-phenyl maleimide ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, tetrafluoroethylene and N-phenyl maleimide ternary copolymerization catalyst and a ternary copolymerization method. The ternary copolymerization method is characterized by comprising the steps of dissolving bis(tricyclohexylphosphine)palladium dichloride and a ligand in a first solvent in a 3-mouth flask in a dry inert atmosphere so as to obtain a mixed solution; dripping titanium iso-propylate to the mixed solution at 150-250 rpm; after the dripping is finished, continuing to stir the materials at a temperature of 30-50 degrees centigrade for 30-50 minutes to obtain a palladium-titanium complex catalyst; taking and adding the norbornene, tetrafluoroethylene and N-phenyl maleimide monomers to a nitrogen charged high pressure kettle which is vacuumized for multiple times; adding a second solvent to the high pressure kettle to dissolve the monomers; and then adding the palladium-titanium complex catalyst to the high pressure kettle and enabling the materials in the high pressure kettle to react at a certain temperature and under a certain pressure; pouring a reaction product into ethanol solution containing hydrochloric acid; washing obtained precipitates by using ethanol to be neutral; and drying the washed precipitates in a vacuum manner to obtain a norbornene, tetrafluoroethylene and N-phenyl maleimide ternary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

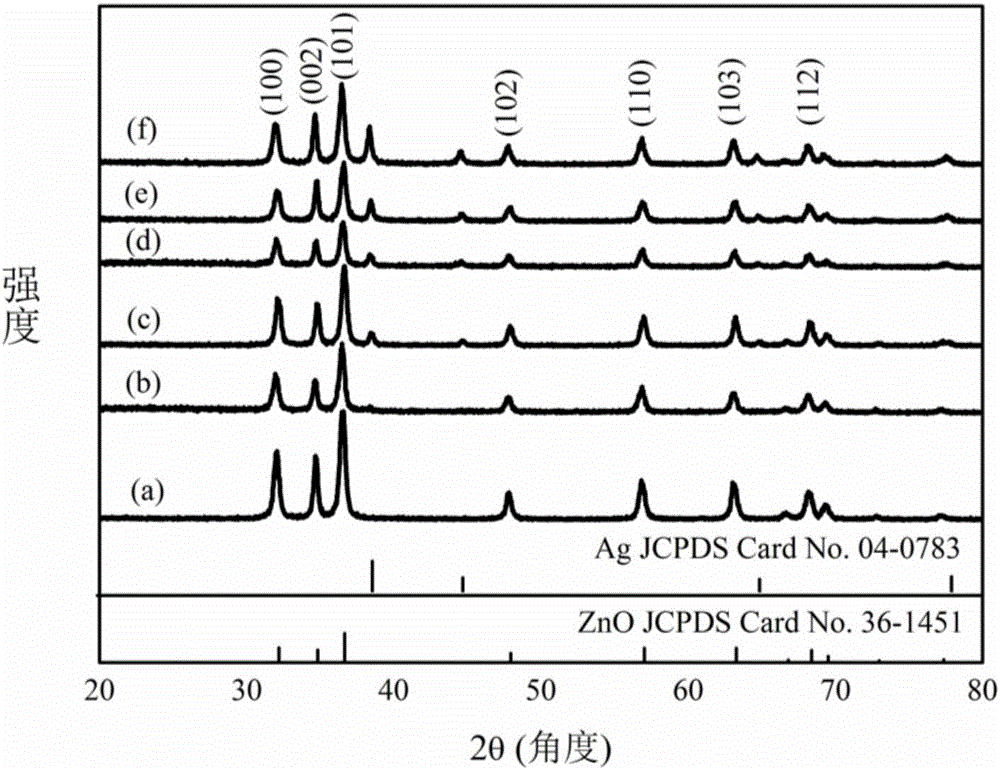

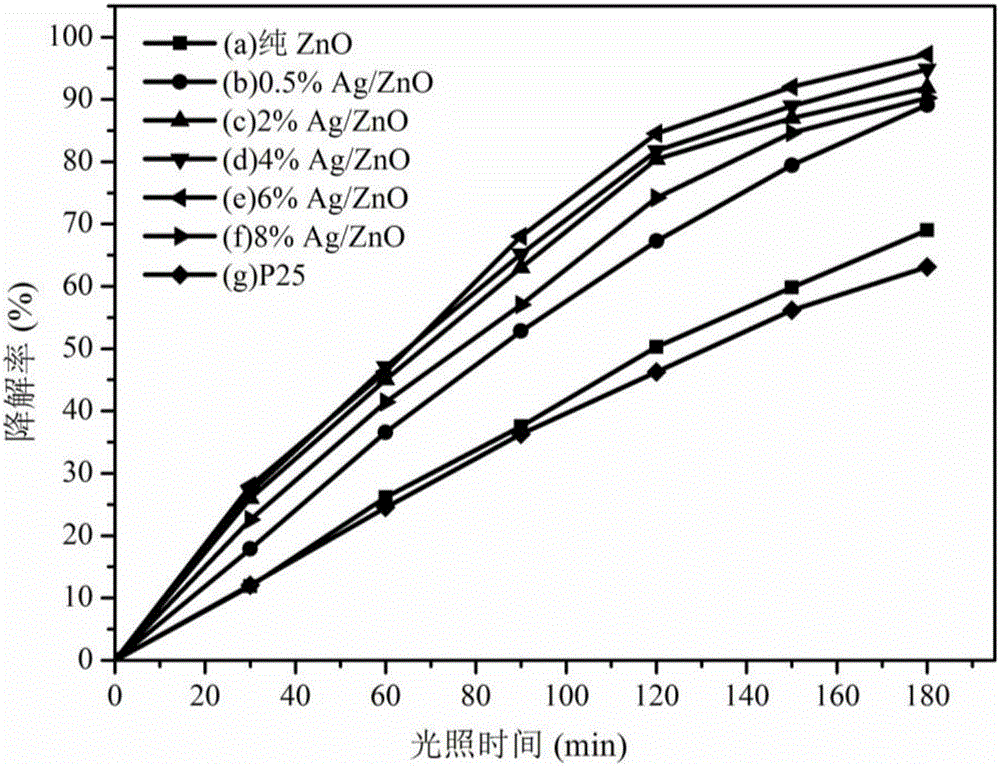

Ag/ZnO nano-composite, preparation method thereof and application of composite

ActiveCN106362742AImprove antibacterial propertiesImprove photocatalytic activityMaterial nanotechnologyBiocidePolyethylene glycolZinc Acetate Dihydrate

The invention belongs to the technical field of ZnO nano-composite materials, and discloses an Ag / ZnO nano-composite, a preparation method thereof and an application of the composite. The method includes the steps: adding zinc acetate dihydrate and silver nitrate into polyethylene glycol, and performing reaction; cooling obtained reaction liquid to indoor temperature after reaction is finished, and centrifugally separating; washing and drying obtained sedimentation to obtain the Ag / ZnO nano-composite. According to the method, by the aid of solvation and stabilization of the polyethylene glycol, the zinc acetate dihydrate and the silver nitrate serve as raw materials, and the Ag / ZnO nano-composite with good dispersibility is prepared by the aid of a one-step method. The method is moderate in reaction condition, simple to operate, rapid, free from pollution, high in production rate, green and environmentally friendly, the raw materials are low in price and easy to obtain, the Ag / ZnO nano-composite is solid powder, conveniently saved and further used, excellent photocatalytic performance is achieved under visible light irradiation, and photocatalytic activities of the Ag / ZnO composites obtained under different silver-zinc mole ratios are superior to those of market photocatalyst P25 and pure ZnO.

Owner:JINAN UNIVERSITY

Norbornene, vinylcyclohexane and perfluoromethyl vinyl ether ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, vinylcyclohexane and perfluoromethyl vinyl ether ternary copolymerization catalyst and a ternary copolymerization method. In a three-neck flask with dry inert gas atmosphere, bis-(1,5-cyclooctadiene) nickel and ligand are dissolved into a first solvent, so that a mixed solution is obtained; then, under stirring, titanium tetraisopropanolate is dripped into the mixed solution, the mixed solution continues to be stirred under 30 DEG C to 70 DEG C for 30 to 70 minutes, and thereby a nickel-titanium complex catalyst is obtained; a norbornene monomer, vinylcyclohexane and a perfluoromethyl vinyl ether monomer are added into a high-pressure kettle which is vacuumized multiple times and filled with nitrogen, and a second solvent is added for dissolution; the nickel-titanium complex catalyst is then added, and reaction takes place under certain temperature and pressure for 1 to 8 hours; the product obtained by the reaction is poured into ethanol solution containing 4 to 5wt percent of hydrochloric acid, the obtained precipitate is washed with ethanol to become neutral, and after vacuum drying, a norbornene, vinylcyclohexane and perfluoromethyl vinyl ether ternary copolymer is obtained.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, acrylics and octafluorocyclopentene ternary polymerization catalyst and ternary polymerization method

The invention relates to a norbornene, acrylics and octafluorocyclopentene ternary polymerization catalyst. The norbornene, acrylics and octafluorocyclopentene ternary polymerization catalyst is characterized in that Fe(6-[1-{(2-methyl)imino}ethyl]-2-acetylpyridine)Cl2, tris(n-butylcyclopentadienyl)yttrium, carbon tetrachloride and a first solvent are placed in an inertia dry single-opening glass bottle, the bottle opening is sealed through a latex tube, and the ternary polymerization catalyst is obtained after dissolution. Norbornene monomers, acrylics monomers and octafluorocyclopentene monomers are prepared according to the mole ratio of 1:1:1, the mixture is added to an inertia dry container, and a second solvent is added to the container so that the mixture can be dissolved. The ternary polymerization catalyst is added and reacts for 2 hours to 8 hours at the constant temperature of 30 DEG C to 90 DEG C, the product is poured into a methanol solution containing 4.5 wt% to 5.5 wt% of hydrochloric acid so that the copolymer can deposit, the sediment is washed through methyl alcohol to be neutral and then dried in vacuum, and then the norbornene, acrylics and octafluorocyclopentene terpolymer is obtained. Raw materials of the catalyst are low in price and can be easily obtained, the catalytic efficiency is high, the reaction temperature is low, and the copolymer yield is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, styrene and cyclohexene ternary copolymerized catalyst and ternary polymerization method

The invention relates to a norbornene, styrene and cyclohexene ternary copolymerized catalyst and a ternary polymerization method. The catalyst is characterized in that a preparation method of the catalyst comprises steps as follows: cyclopentadienyl manganese tricarbonyl and a ligand are dissolved in a first solvent in a 3-mouth flask having the dry inert atmosphere, a mixed solution is obtained and put in an electric mixer, titanium isopropoxide is dropwise added to the mixed solution at the speed of 150-250 rpm and continuously stirred at the temperature of 20-50 DEG C for 20-50 min after dropwise adding ends, and a manganese-titanium complex catalyst is obtained; the ternary polymerization method comprises steps as follows: norbornene monomers, styrene and cyclohexene monomers are taken in a mole ratio and added to a high-pressure kettle which is repeatedly vacuumized and charged with nitrogen, and a second solvent is added for dissolving; then the added manganese-titanium complex catalyst is subjected to reaction under certain conditions; a product obtained through a reaction is poured into an ethanol solution containing 4wt%-5wt% hydrochloric acid, obtained precipitates are washed to be neutral with ethanol, vacuum drying is performed, and a norbornene, styrene and cyclohexene ternary copolymer is obtained.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, hexafluoropropylene and N-phenyl maleimide ternary polymerization catalyst and method

The invention relates to a norbornene, hexafluoropropylene and N-phenyl maleimide ternary polymerization catalyst and method. The ternary polymerization catalyst and method is characterized in that a preparation method of the catalyst includes: dissolving molybdenum acetate and ligand in a first solvent in a dry three-mouth flask with inert atmosphere to obtain a mixed solution; dropping titanium tetrachloride into the mixed solution at 150-250rpm, and stirring at 20-50 DEG C for 20-50min after dropping to obtain a molybdenum-titanium complex catalyst; adding norbornene monomer, hexafluopropylene and N-phenyl maleimide monomer into a high-pressure kettle which is vacuumized and nitrogenized several times according to a molar ratio of 1:1:1, and adding a second solvent for dissolving; adding the molybdenum-titanium complex catalyst, and allowing reaction at 30-150 DEG C and 0.1-8MPa for 1-6h; washing a reaction product, washing obtained precipitate to neutral, and vacuum drying to obtain norbornene, hexafluoropropylene and N-phenyl maleimide ternary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst and a ternary copolymerization method. The norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst is characterized in that a preparation method for the norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst comprises the steps of dissolving titanocene dichloride and a ligand in a first solvent in a 3-mouth flask in a dry inert atmosphere; dripping aluminum alkyl to the 3-mouth flask at 130-170 rpm; after the dripping is finished, stirring the materials at a constant temperature of 30-60 degrees centigrade for 30-60 minutes to obtain a titanium-aluminum complex catalyst; taking norbornene, octafluorocyclopentene and N-phenyl maleimide monomers according to a mole ratio of 1:1:1; adding the norbornene, octafluorocyclopentene and N-phenyl maleimide monomers to a nitrogen charged reaction kettle which is vacuumized for multiple times; adding a second solvent to the reaction kettle to dissolve the monomers; and then adding the titanium-aluminum complex catalyst to the reaction kettle and enabling the materials in the reaction kettle to react at a certain temperature and under a certain pressure; pouring a reaction product into ethanol solution containing 4-5wt% hydrochloric acid; washing obtained precipitates by using ethanol to be neutral; and drying the washed precipitates in a vacuum manner to obtain a norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

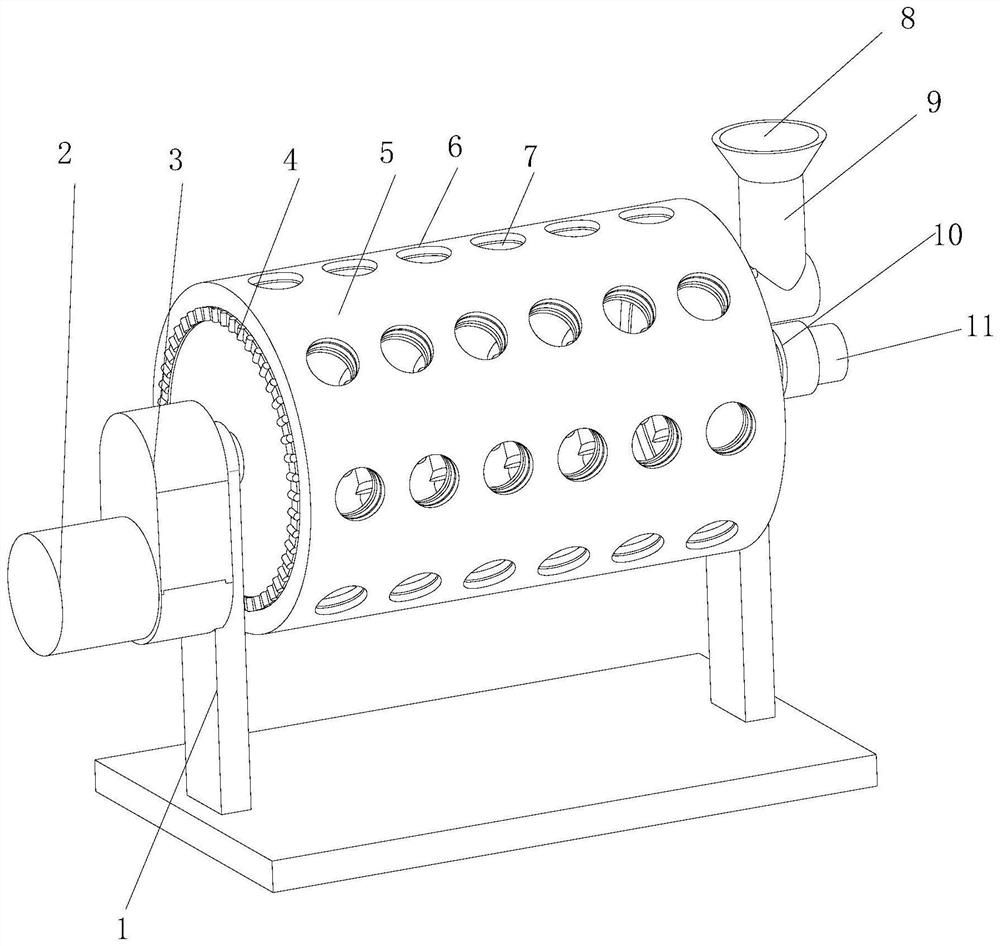

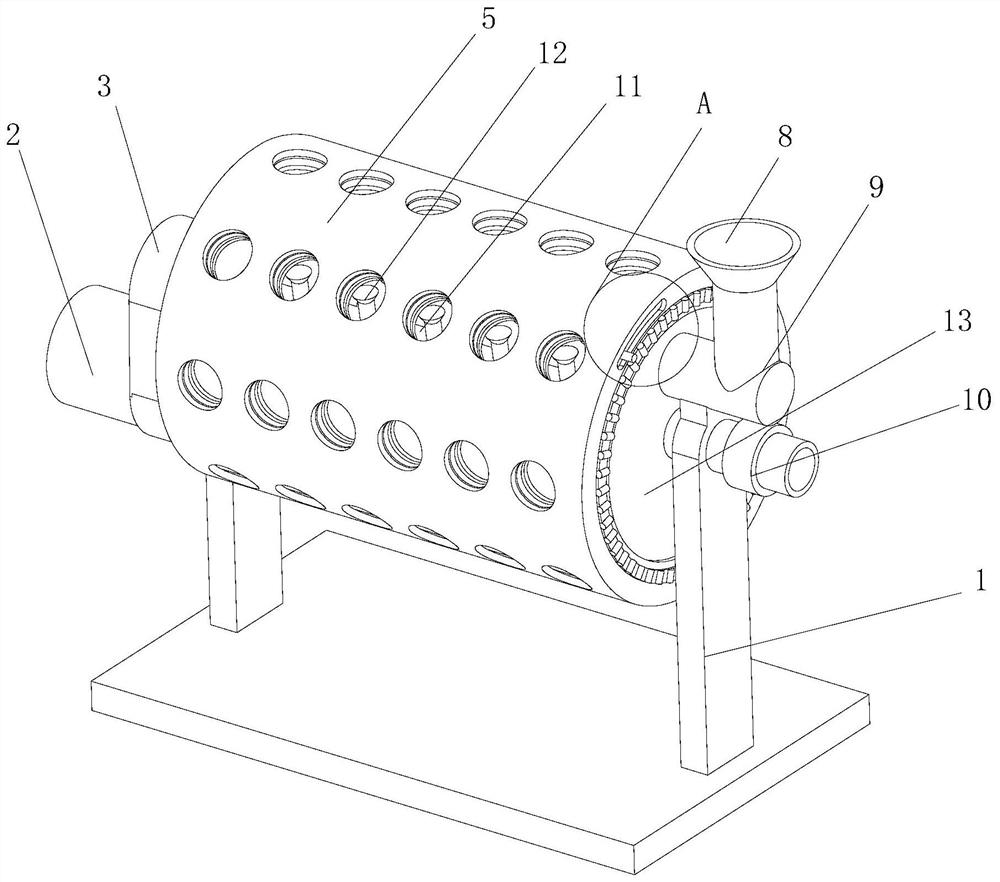

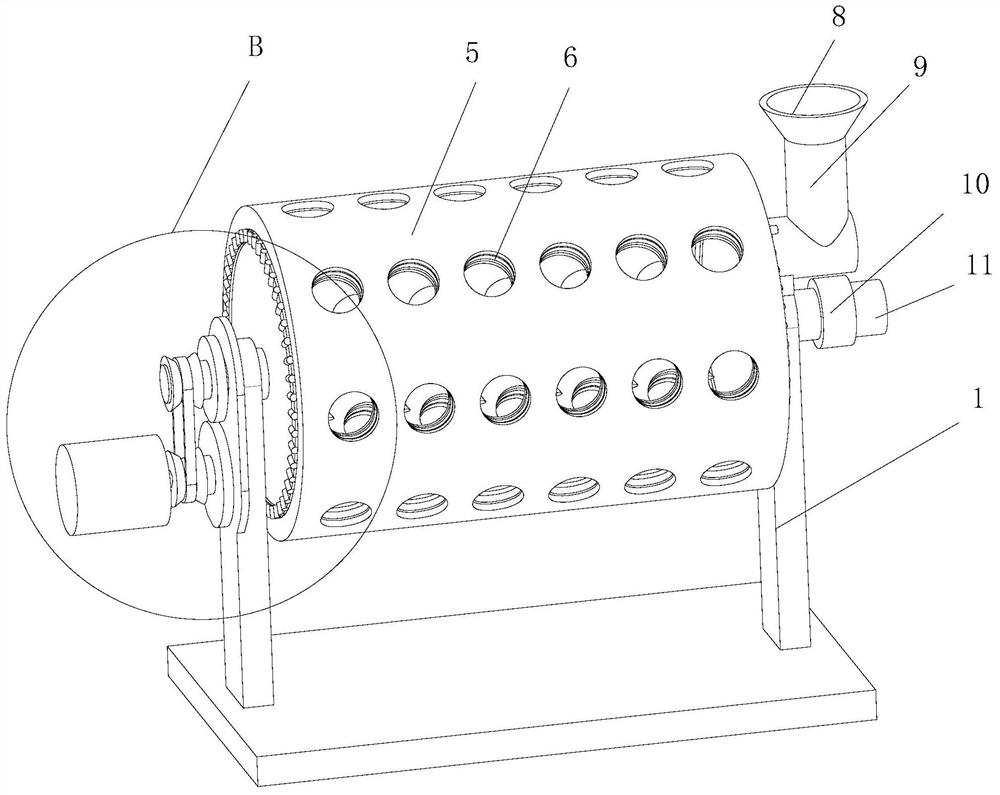

Rapid soil removing device for earthworm breeding

InactiveCN112154978AQuick removalProcessing effectAnimal husbandryAgricultural scienceMechanical engineering

The invention relates to the technical field of earthworm breeding, and discloses a rapid soil removing device for earthworm breeding. The device comprises supporting legs, outer rods are arranged inside the supporting legs; an outer box is fixedly connected with the surfaces of the outer rods; and first leaking holes are formed in the surfaces of the outer box. According to the rapid soil removing device for earthworm breeding, a motor is started to drive a second concave gear to rotate, then a chain drives a first concave gear and a water pipe to rotate, then the water pipe is made to rotatereversely, meanwhile, a second gear drives a first gear to rotate, the outer rods and the outer box are made to rotate, and forward rotation is conducted. Therefore, earthworms can be conveniently separated from the soil, and the earthworms are processed, the soil of the earthworm processing process is reduced, so that bacterium breeding is prevented, the effect after cleaning is improved, the cleanness and tidiness of the earthworms are guaranteed, and the influence on later processing of the earthworms due to incomplete cleaning is avoided.

Owner:李延平

Norbornene, acrylonitrile and N-phenyl maleimide ternary polymerization catalyst and ternary polymerization method

The invention relates to a norbornene, acrylonitrile and N-phenyl maleimide ternary polymerization catalyst and a ternary polymerization method. The ternary polymerization catalyst is characterized in that the preparation method of the catalyst comprises the steps that in a three-necked flask in a dry inert gas atmosphere, zirconium naphthenate and a ligand are dissolved in a first solvent, and a mixed solution is obtained; aluminum alkyl is dropwise added into the mixed solution under stirring, after dropping addition is completed, reacting is conducted at the temperature of 20-50 DEG C for 20-50 min, and a zirconium-aluminum complex catalyst is obtained; a norbornene monomer, acrylonitrile and an N-phenyl maleimide monomer are obtained to be added into an autoclave which is vacuumized repeatedly and filled with nitrogen, and a second solvent is added for dissolving; then the zirconium-aluminum complex catalyst is added for reacting at a certain temperature and pressure for 1-6 hours; a product obtained from the reaction is poured into an alcohol solution, an obtained sediment is washed with alcohol to be neutral, and the norbornene, acrylonitrile and N-phenyl maleimide ternary copolymer is obtained after vacuum drying.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene and vinylene carbonate binary copolymerized catalyst and binary copolymerization method

The invention relates to a norbornene and vinylene carbonate binary copolymerized catalyst, and is characterized in that a preparation method of the catalyst comprises the following steps: in a dry three-neck flask with an inert gas atmosphere, dissolving tri(butylcyclopentadienyl)scandium and a ligand in a first solvent, dropping diethyl zinc at a speed rate of 150-300 rpm, and after the dropping is completed, carrying out isothermal stirring for 30-60 minutes at the temperature of 30-60 DEG C at the same stirring speed rate, to obtain a scandium-zinc complex catalyst; taking norbornene and vinylene carbonate monomers according to the molar ratio of 1:1, adding the components into a reaction kettle vacuumized for multiple times and filled with nitrogen, adding a second solvent, and dissolving; then adding the scandium-zinc complex catalyst, and carrying out a reaction for 1-6 hours at the temperature of 20-130 DEG C and the pressure of 0.1-8 MPa; and pouring the product obtained from the reaction into an ethanol solution containing 4.5-5.5 wt% of hydrochloric acid, washing an obtained precipitate with ethanol to be neutral, and vacuum-drying to obtain the norbornene and vinylene carbonate binary copolymerized catalyst.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, tetrafluoroethylene and n-phenylmaleimide ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, tetrafluoroethylene and N-phenyl maleimide ternary copolymerization catalyst and a ternary copolymerization method. The ternary copolymerization method is characterized by comprising the steps of dissolving bis(tricyclohexylphosphine)palladium dichloride and a ligand in a first solvent in a 3-mouth flask in a dry inert atmosphere so as to obtain a mixed solution; dripping titanium iso-propylate to the mixed solution at 150-250 rpm; after the dripping is finished, continuing to stir the materials at a temperature of 30-50 degrees centigrade for 30-50 minutes to obtain a palladium-titanium complex catalyst; taking and adding the norbornene, tetrafluoroethylene and N-phenyl maleimide monomers to a nitrogen charged high pressure kettle which is vacuumized for multiple times; adding a second solvent to the high pressure kettle to dissolve the monomers; and then adding the palladium-titanium complex catalyst to the high pressure kettle and enabling the materials in the high pressure kettle to react at a certain temperature and under a certain pressure; pouring a reaction product into ethanol solution containing hydrochloric acid; washing obtained precipitates by using ethanol to be neutral; and drying the washed precipitates in a vacuum manner to obtain a norbornene, tetrafluoroethylene and N-phenyl maleimide ternary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene-based and vinylene carbonate binary copolymerization catalyst and binary copolymerization method

The invention relates to a norbornene and vinylene carbonate binary copolymerized catalyst, and is characterized in that a preparation method of the catalyst comprises the following steps: in a dry three-neck flask with an inert gas atmosphere, dissolving tri(butylcyclopentadienyl)scandium and a ligand in a first solvent, dropping diethyl zinc at a speed rate of 150-300 rpm, and after the dropping is completed, carrying out isothermal stirring for 30-60 minutes at the temperature of 30-60 DEG C at the same stirring speed rate, to obtain a scandium-zinc complex catalyst; taking norbornene and vinylene carbonate monomers according to the molar ratio of 1:1, adding the components into a reaction kettle vacuumized for multiple times and filled with nitrogen, adding a second solvent, and dissolving; then adding the scandium-zinc complex catalyst, and carrying out a reaction for 1-6 hours at the temperature of 20-130 DEG C and the pressure of 0.1-8 MPa; and pouring the product obtained from the reaction into an ethanol solution containing 4.5-5.5 wt% of hydrochloric acid, washing an obtained precipitate with ethanol to be neutral, and vacuum-drying to obtain the norbornene and vinylene carbonate binary copolymerized catalyst.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornenes, acrylonitrile and n-phenylmaleimide terpolymerization catalyst and terpolymerization method

The invention relates to a norbornene, acrylonitrile and N-phenyl maleimide ternary polymerization catalyst and a ternary polymerization method. The ternary polymerization catalyst is characterized in that the preparation method of the catalyst comprises the steps that in a three-necked flask in a dry inert gas atmosphere, zirconium naphthenate and a ligand are dissolved in a first solvent, and a mixed solution is obtained; aluminum alkyl is dropwise added into the mixed solution under stirring, after dropping addition is completed, reacting is conducted at the temperature of 20-50 DEG C for 20-50 min, and a zirconium-aluminum complex catalyst is obtained; a norbornene monomer, acrylonitrile and an N-phenyl maleimide monomer are obtained to be added into an autoclave which is vacuumized repeatedly and filled with nitrogen, and a second solvent is added for dissolving; then the zirconium-aluminum complex catalyst is added for reacting at a certain temperature and pressure for 1-6 hours; a product obtained from the reaction is poured into an alcohol solution, an obtained sediment is washed with alcohol to be neutral, and the norbornene, acrylonitrile and N-phenyl maleimide ternary copolymer is obtained after vacuum drying.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

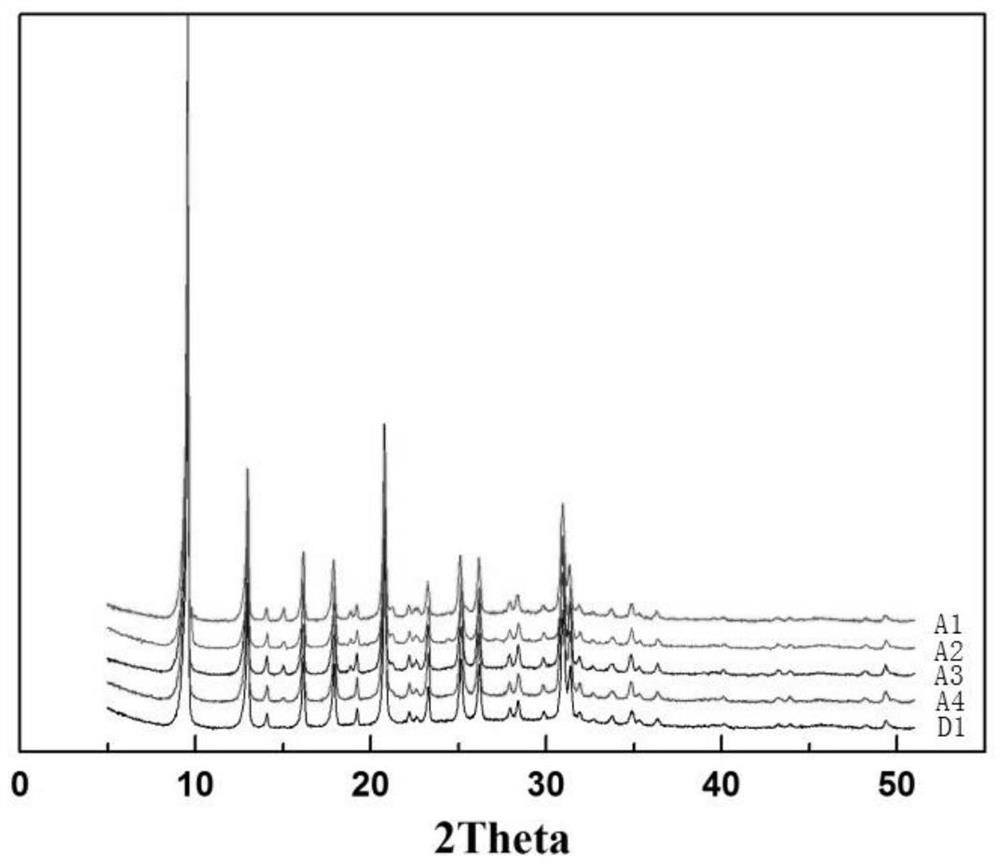

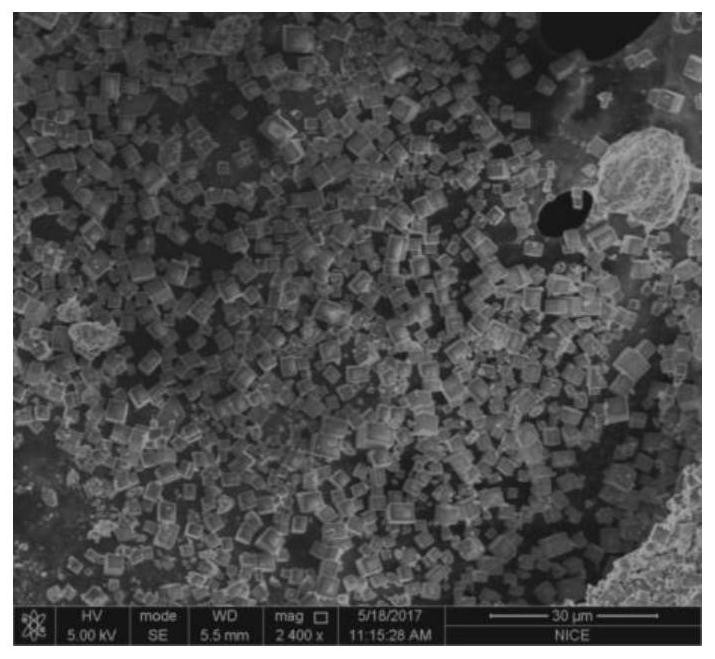

Sapo-34 molecular sieve and its preparation method and application

ActiveCN110240179BLow priceLow costMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMeth-Chemical reaction

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com