Copper based nanometer/micron composite particles as well as preparation method and application thereof

A technology of composite particles and copper-based nanotechnology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of long time required for photocatalytic degradation of organic pollutants, unfavorable large-scale industrial production, and complex cost of raw materials , to achieve excellent antibacterial and catalytic properties, good application prospects, and easy washing and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation method of copper-based oxide composite particles:

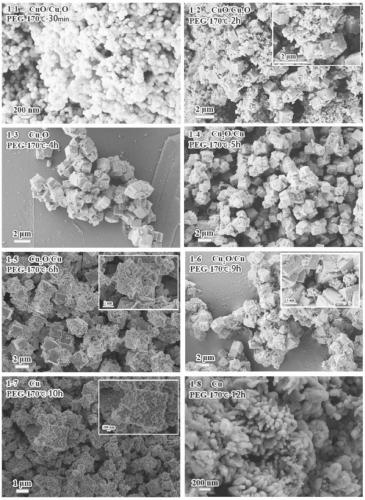

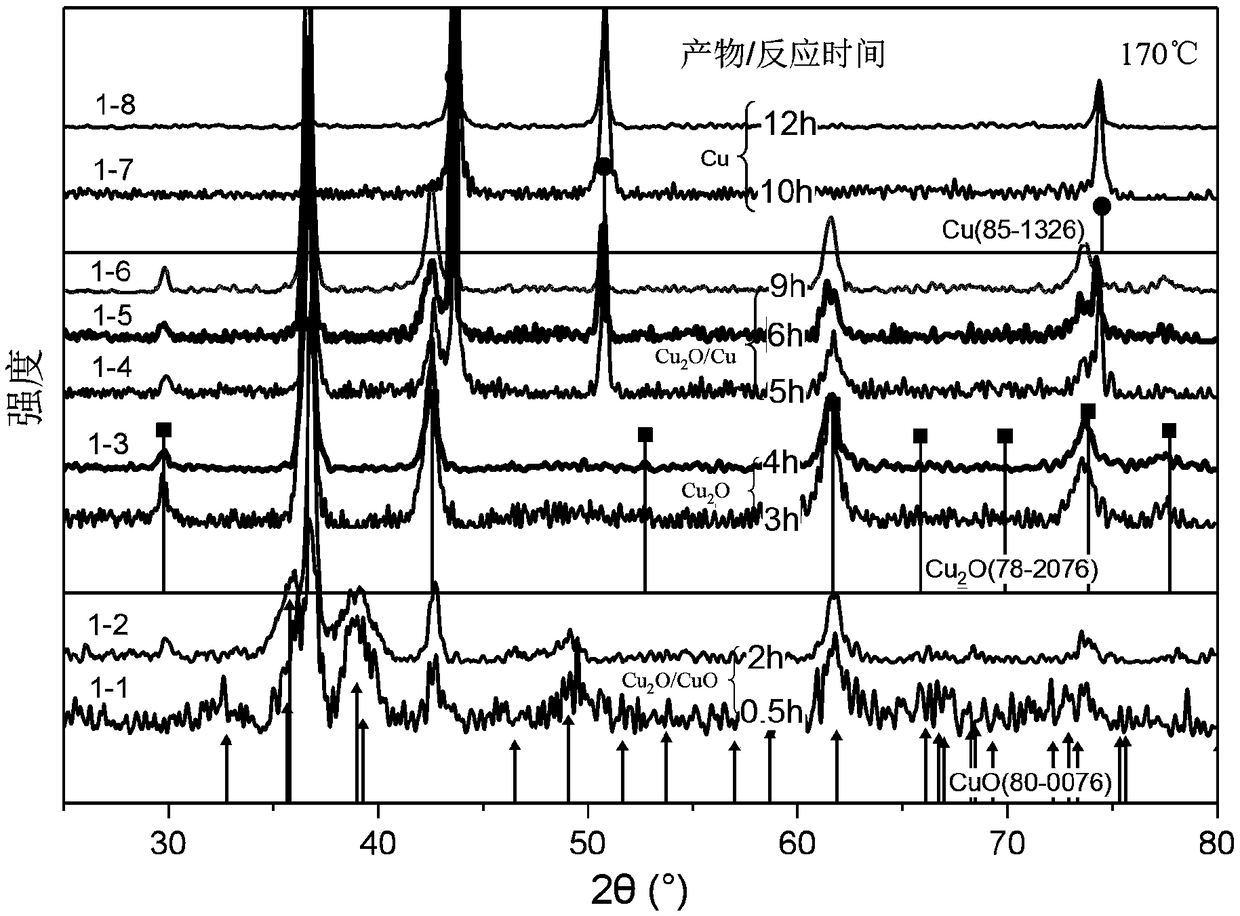

[0034] (1) Accurately measure 40.0mL PEG-400 and weigh (0.8000g) 4.0mmol Cu(CH 3 COO) 2 ·H 2 O in a 100mL flask that has been washed and dried, heated to 170°C in an oil bath, stirred and reacted at this temperature for 30 minutes, then cooled to room temperature naturally, washed and centrifuged twice with deionized water, and then washed with absolute ethanol Centrifuge, and finally dry in a 60°C oven to obtain solid spherical powder CuO / Cu 2 The composite particles of O are referred to as sample 1-1, and the average particle diameter is 100 nm.

[0035] (2) According to the operation procedure of above-mentioned (1), change the reaction time into 2h, 4h, 5h, 6h, 9h, 10h and 12h respectively to carry out the experiment, and the products obtained are respectively recorded as samples 1-2, 1-3, 1-4, 1-5, 1-6, 1-7 and 1-8, the obtained product 1-2 is spherical cuprous oxide and cubic cuprous oxide mixed p...

Embodiment 2

[0039] Preparation method of copper-based oxide composite particles:

[0040] (1) Accurately weigh (0.8000g) 4.0mmol Cu(CH 3 COO) 2 ·H 2 O and measure 20mL of deionized water in a beaker, stir to dissolve and pour into a 100mL flask filled with 40.0mL PEG-400. The volume ratio of water to PEG is 50%, and the oil bath is heated to 120°C. After stirring and reacting for 10 minutes, cool naturally to room temperature, wash and centrifuge the product twice with deionized water, then wash and centrifuge with absolute ethanol, and finally put it in a 60°C oven to dry to obtain solid powder copper-based oxide (CuO) The composite particles are referred to as sample 2-1, with an average particle diameter of 155 nm.

[0041] (2) According to the operation procedure of above-mentioned (1), change the reaction time into 1h, 2h, 4h, 6h successively, carry out the experiment, make solid powdery copper-based oxide composite particles, denote respectively as sample 2-2, 2 -3, 2-4 and 2-5,...

Embodiment 3

[0046] Preparation method of copper-based sulfide composite particles:

[0047] Accurately measure 7 groups of raw materials, each group of raw materials includes 40.0mL PEG-400 and (0.8000g) 4.0mmol Cu(CH 3 COO) 2 ·H 2 O, placed in a washed and dried 100mL flask, and then adding copper-sulfur molar ratios of 1:0.1, 1:0.25, 1:0.5, 1:0.75, 1:1, 1:2, 1:3, that is, 0.0128g, 0.0321g, 0.0642g, 0.0963g, 0.1280g, 0.2600g, 0.4000g of sublimed sulfur, heating the oil bath to 120°C, stirring magnetically at this temperature for 2h and then cooling to room temperature naturally, the product Wash and centrifuge twice with deionized water first, then wash and centrifuge with absolute ethanol, and finally put it into a 60°C oven for drying. Obtain solid powdery copper-based sulfide composite particles, respectively marked as samples 3-1, 3-2, 3-3, 3-4, 3-5, 3-6 and 3-7, wherein the synthesis of sample 3-1 The product is irregular flaky Cu with an average particle size of 1000 nm 2 S, C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com