Ag/ZnO nano-composite, preparation method thereof and application of composite

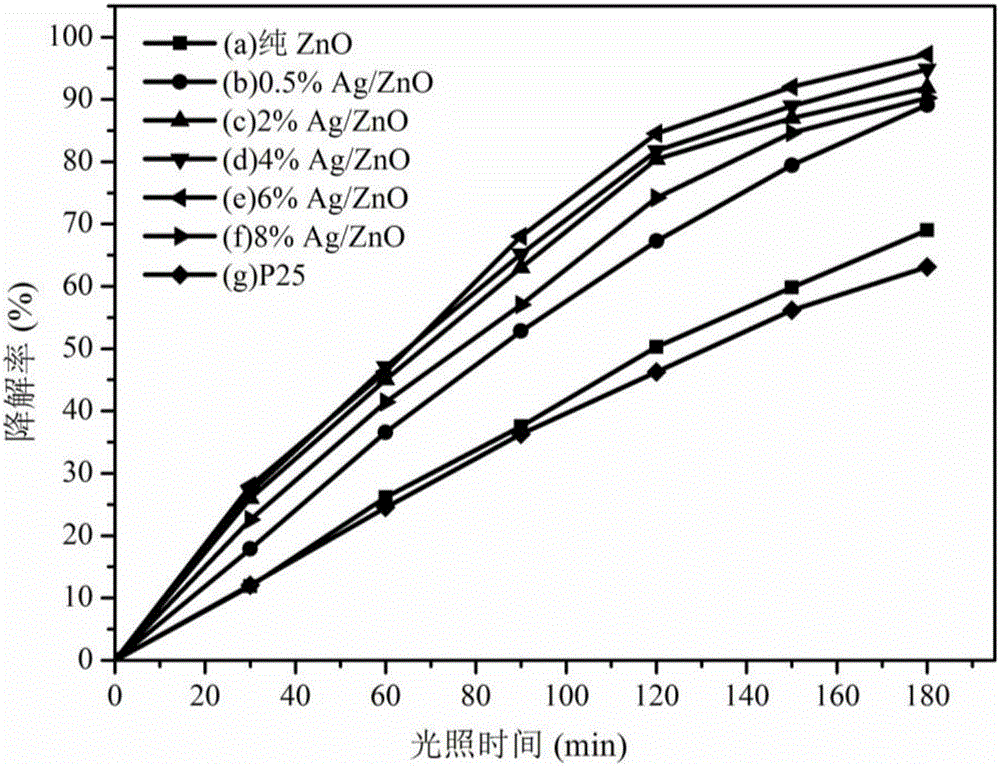

A nanocomposite and reaction technology, applied in the direction of botany equipment and methods, applications, nanotechnology, etc., can solve the problems of long time required for photocatalytic degradation of organic pollutants, complicated experimental operations, incomplete degradation, etc., and achieve good results Photocatalytic performance, cheap and easy-to-obtain raw materials, and good preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

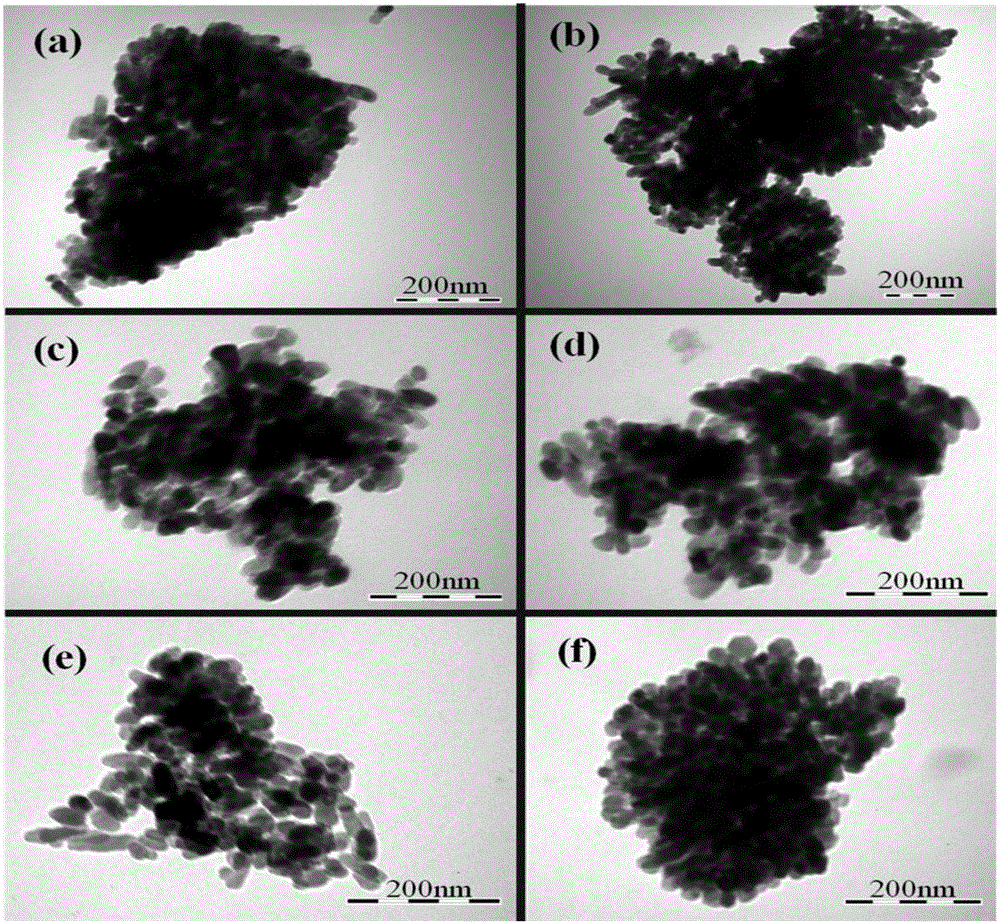

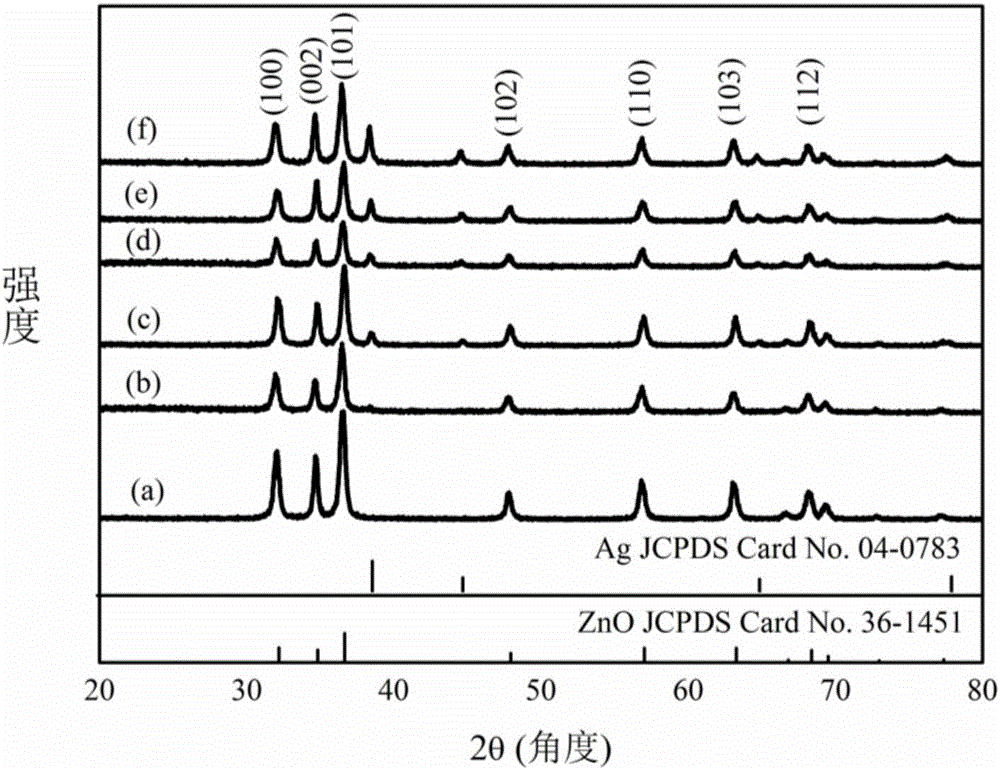

[0031] Add 10mmol of zinc acetate dihydrate and 0.2mmol of silver nitrate into 40.00mL PEG-200 at 180°C and magnetically stir for 0.5h to obtain a gray turbid solution. Cool naturally to room temperature, centrifuge the product, separate the supernatant sol clear liquid and precipitate, wash the obtained precipitate three times with secondary water and absolute ethanol, and dry in an oven at 80°C. The product was then sealed for further characterization.

Embodiment 2

[0033] Add 10mmol of zinc acetate dihydrate and 0.2mmol of silver nitrate into 40.00mL PEG-200 at 180°C for 2h with magnetic stirring to obtain a gray turbid solution. Cool naturally to room temperature, centrifuge the product, separate the supernatant sol clear liquid and precipitate, wash the obtained precipitate three times with secondary water and absolute ethanol, and dry in an oven at 80°C. The product was then sealed for further characterization.

Embodiment 3

[0035] Add 10mmol of zinc acetate dihydrate and 0.2mmol of silver nitrate into 40.00mL PEG-200 at 160°C and stir magnetically for 1h to obtain a gray cloudy solution. Cool naturally to room temperature, centrifuge the product, separate the supernatant sol clear liquid and precipitate, wash the obtained precipitate three times with secondary water and absolute ethanol, and dry in an oven at 80°C. The product was then sealed for further characterization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com