Preparation method of recyclable and reusable hydrogenation catalyst

A hydrogenation catalyst, silica technology, applied in catalyst carriers, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem that the catalyst cannot be recycled and reused, the reaction temperature is high, and the catalyst preparation Complex process and other problems, to achieve good recycling effect, simple preparation process, storage and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

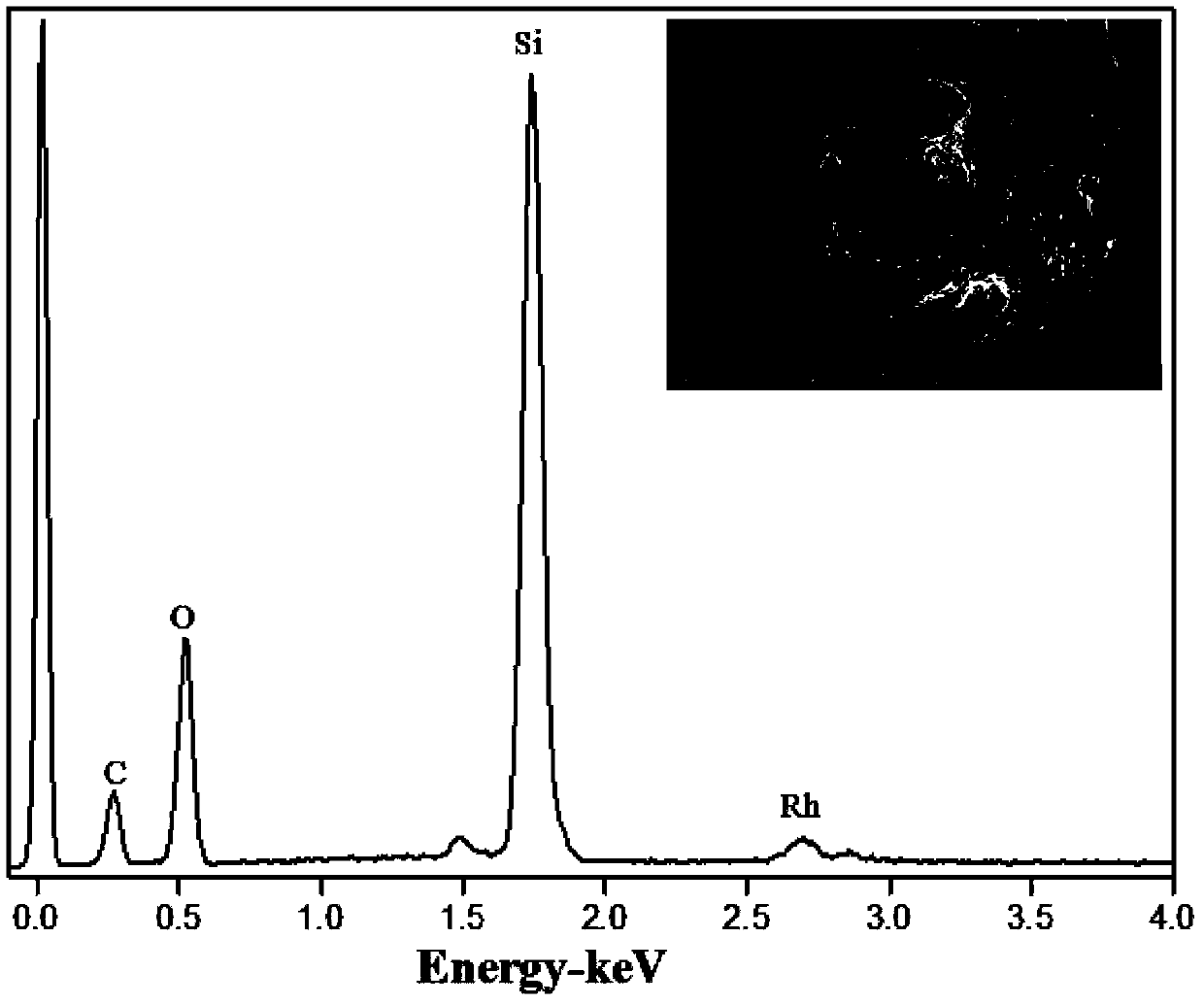

[0028] Modification of silicon dioxide: prepare 1.5L of 1.5g / L dopamine hydrochloride solution, adjust the pH value to 8.5 with tris, put 15g of silicon dioxide into the solution, stir and react at room temperature for 24h, and then carry out Wash with water and dry at 60° C. for 48 hours to obtain dopamine-modified silica.

[0029] Preparation of catalyst precursor: Take 5g of the above-mentioned modified silica into the reactor, add 200mL of deionized water and 40mL of 200mM RhCl3 aqueous solution in sequence, react at 45°C for 10h, then wash with water and dry at 60°C 48h, the catalyst precursor was obtained.

[0030] Preparation of hydrogenation catalyst: put the prepared catalyst precursor in the reactor and add 150mL deionized water and 80mL 1% NaBH 4 The aqueous solution was reacted at 50°C for 8 hours, then washed with water, and finally baked at 60°C for 48 hours to obtain a hydrogenation catalyst.

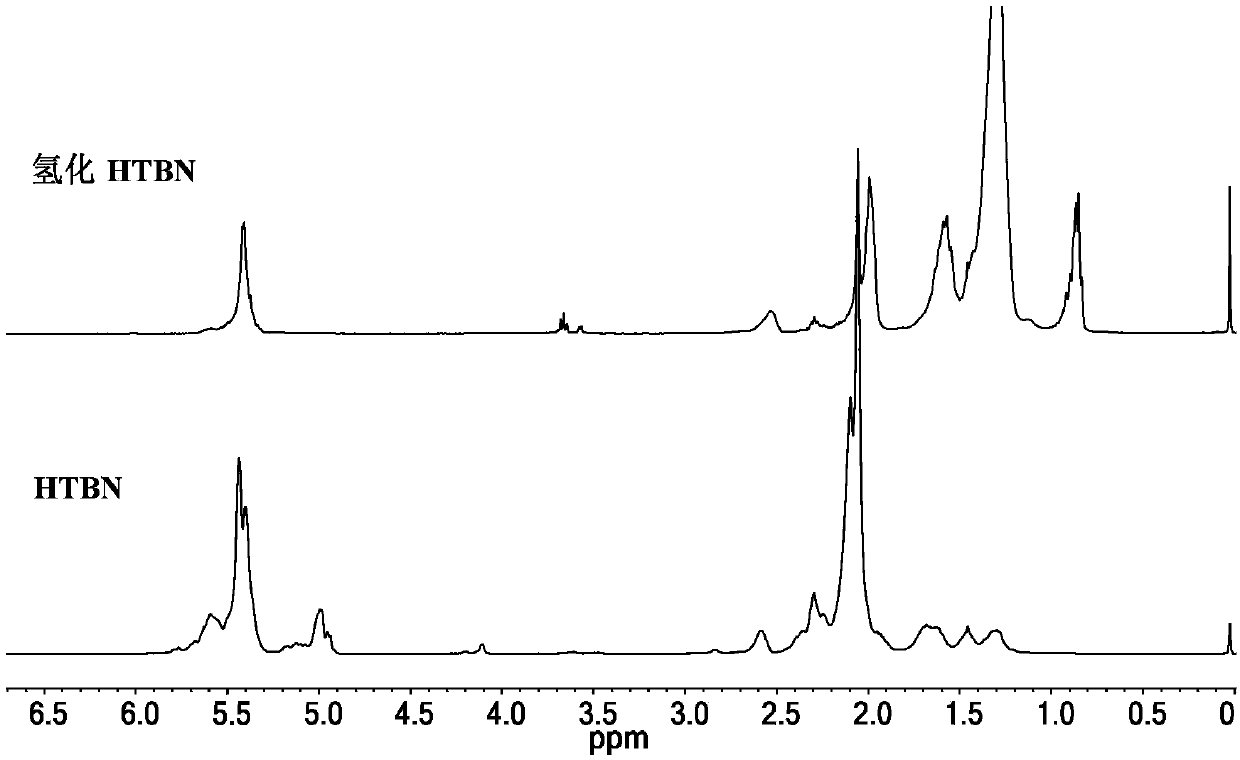

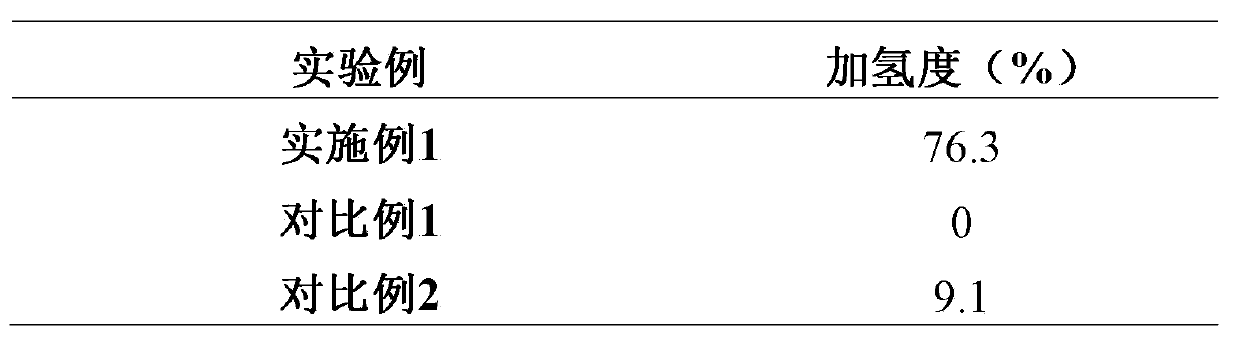

[0031] According to the general hydrogenation procedure above, mea...

Embodiment 2

[0039] Change the amount of hydrogenation catalyst in embodiment 1 to 0.1g, 1g, others are the same as embodiment 1, and the results are shown in table 2.

[0040] Table 2

[0041]

Embodiment 3

[0043] Change the hydrogenation reaction temperature in Example 1 to 25° C., 100° C., and others are the same as in Example 1. The results are shown in Table 3.

[0044] table 3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com