Carbonization device of rotten garbage treatment

A waste treatment and carbonization device technology, applied in carbonization furnaces, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increasing the processing cost of carbonization devices and low purity of biochar, so as to save equipment costs and reduce energy consumption , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

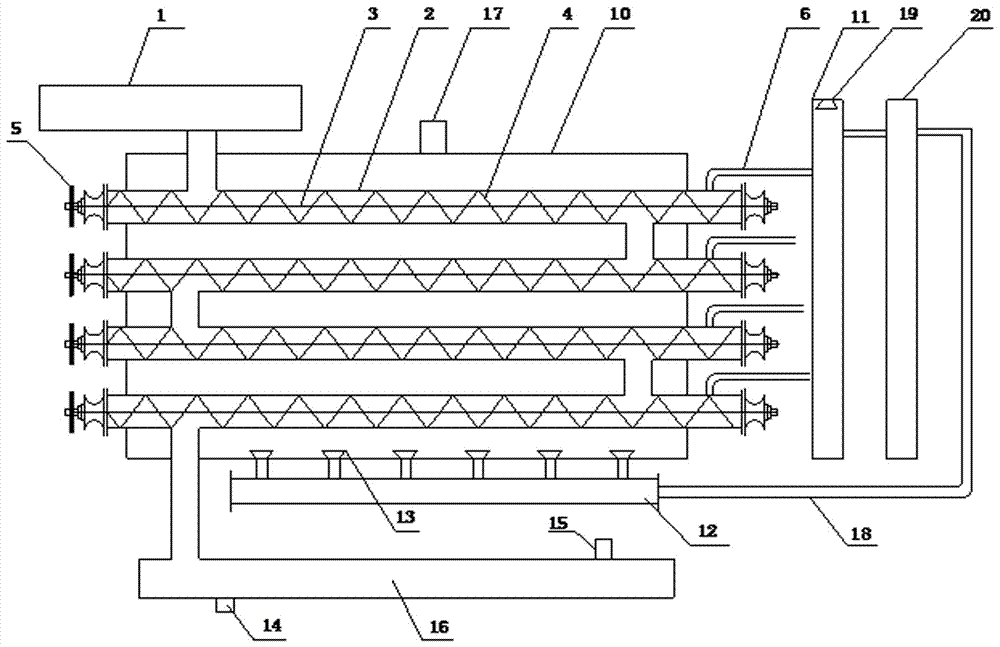

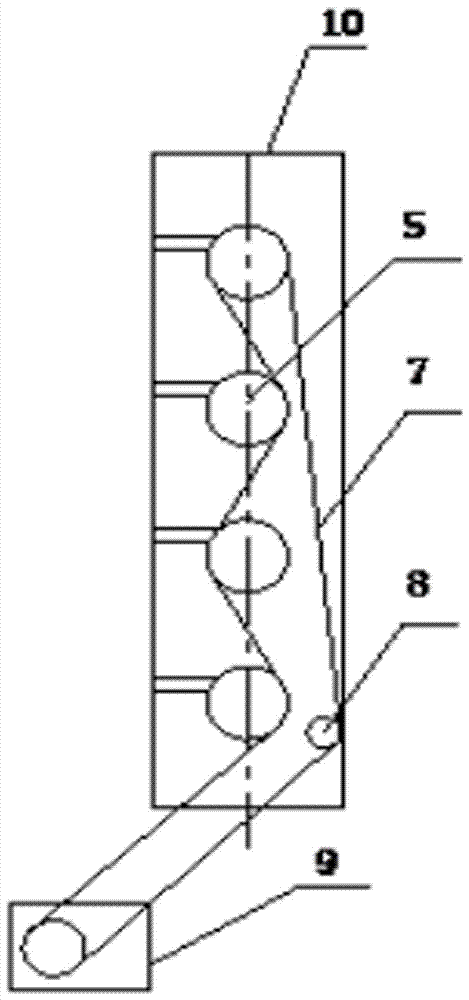

[0031] Attached below figure 1 and attached figure 2 , describe the present invention in detail.

[0032] Such as figure 1As shown, the carbonization device for perishable garbage treatment of the present invention includes: feed screw 1, carbonizer 10, spray tower 11, cooling tower 20, combustible gas recycling tank 12, transmission motor 9 and discharge screw 16 , several delivery pipes 2 are installed in the carbonizer 10 from top to bottom, for example: 4 delivery pipes 2 . A rotating shaft 3 is installed in the conveying pipe 2, and a spiral plate 4 is installed on the rotating shaft 3 in the conveying pipe 2. The direction of rotation of the spiral plate 4 in the adjacent conveying pipe 2 is opposite, and the uppermost conveying pipe 2 and the feeding screw 1 connected, the lowermost conveying pipe 2 is connected with the discharge screw 16, the outlet of the previous conveying pipe 2 is connected with the entrance of the next conveying pipe 2, and the air outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com