Two-stage type lignin steaming and cooking separation device

A lignin and two-stage technology, which is applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost, large floor area, and shutdown, so as to save power and reduce equipment investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

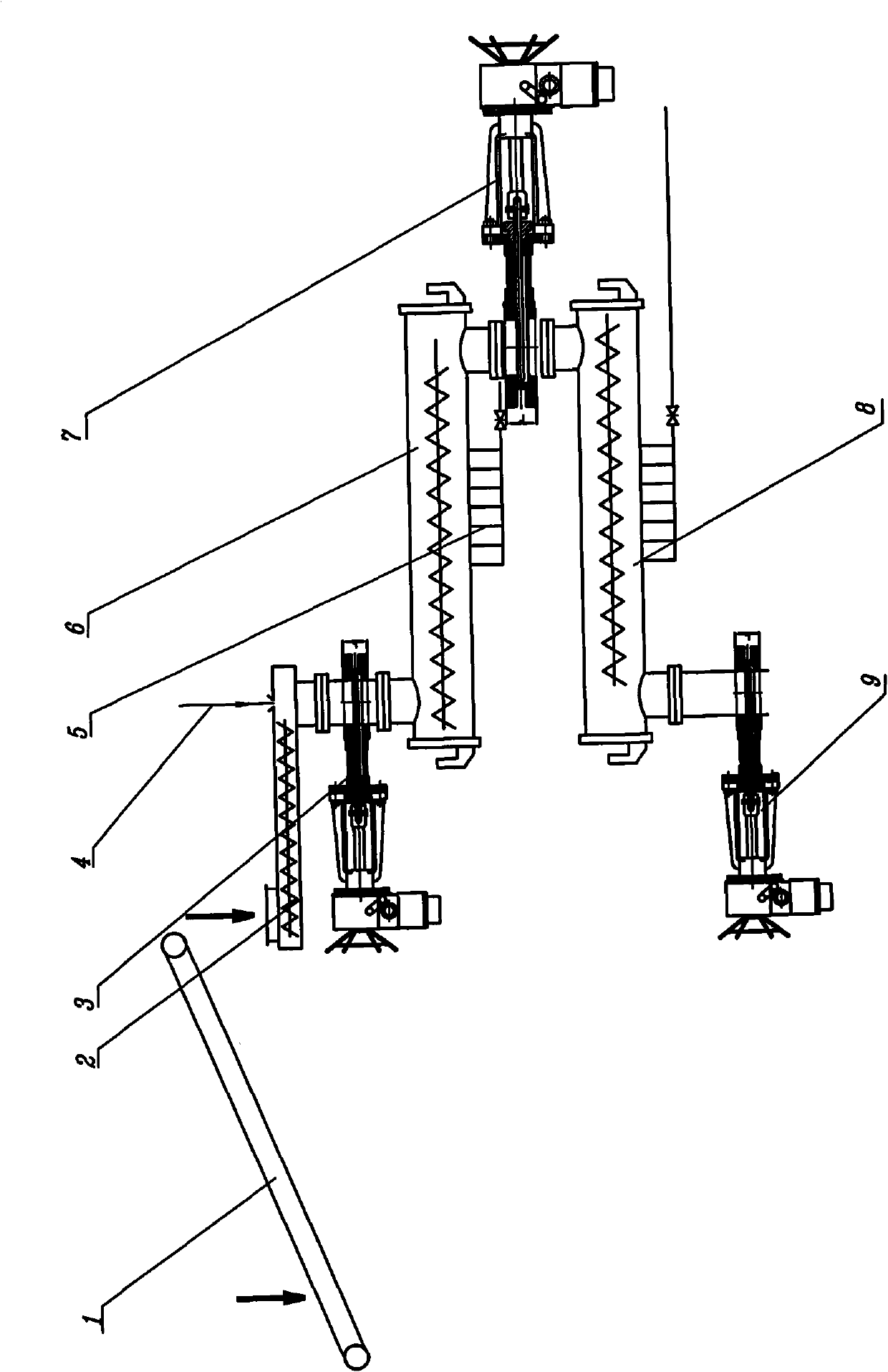

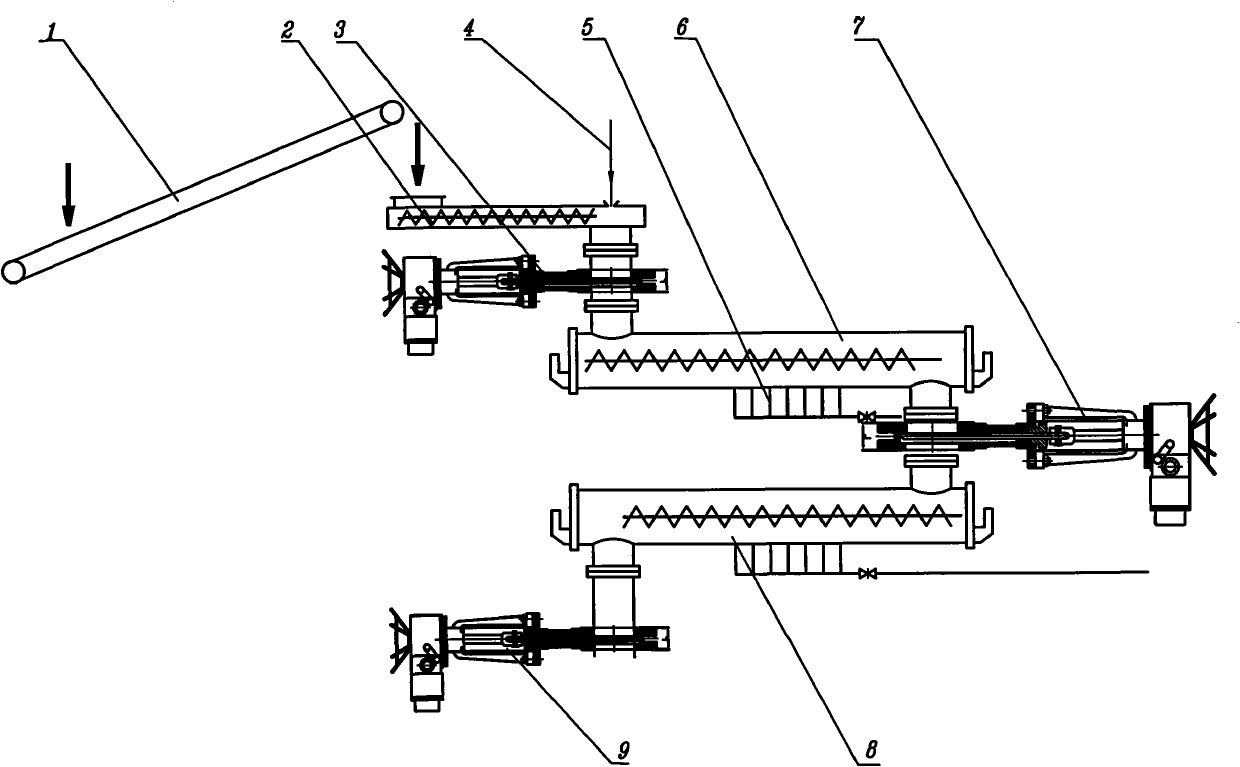

[0015] Open the feeding electric gate valve 3, close the electric gate valve 7, the belt conveyor 1 measures and feeds the raw materials that have been pretreated by steam explosion, and feeds them through the screw conveyor mixer 2. The lye is added from the catalyst inlet 4, and the materials pass through the open feeding The material electric gate 3 enters the heating chamber 6, and after the metering requirement is met, the feeding electric gate 3 is closed, and the heating chamber 6 is fed with steam through the steam inlet 5 for cooking.

[0016] After the design temperature (100-120°C) is reached, the electric gate 7 is opened, and the materials in the heating chamber 6 are transported to the heat preservation chamber 8 through a spiral structure. After the material conveying is completed, close the electric gate 7, feed steam to the heat preservation bin 8, and carry out the second section of cooking. Open the feeding electric gate 3, and simultaneously the raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com