Biomass gasification and carbonization treatment method and integrated device

A technology of carbonization treatment and biomass, applied in the direction of biofuel, manufacture of combustible gas, special form of dry distillation, etc., to achieve high comprehensive utilization rate, improve heat utilization rate, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

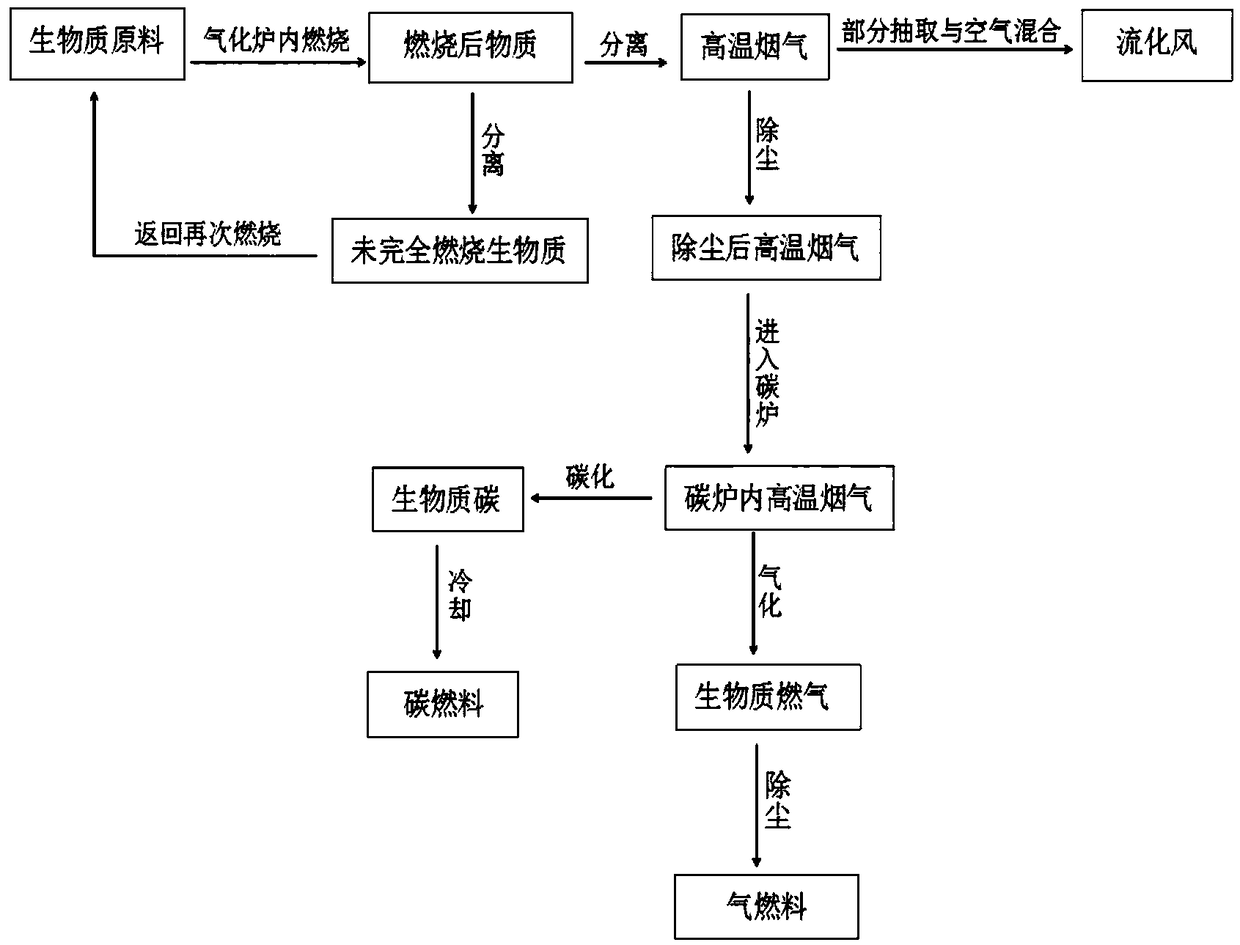

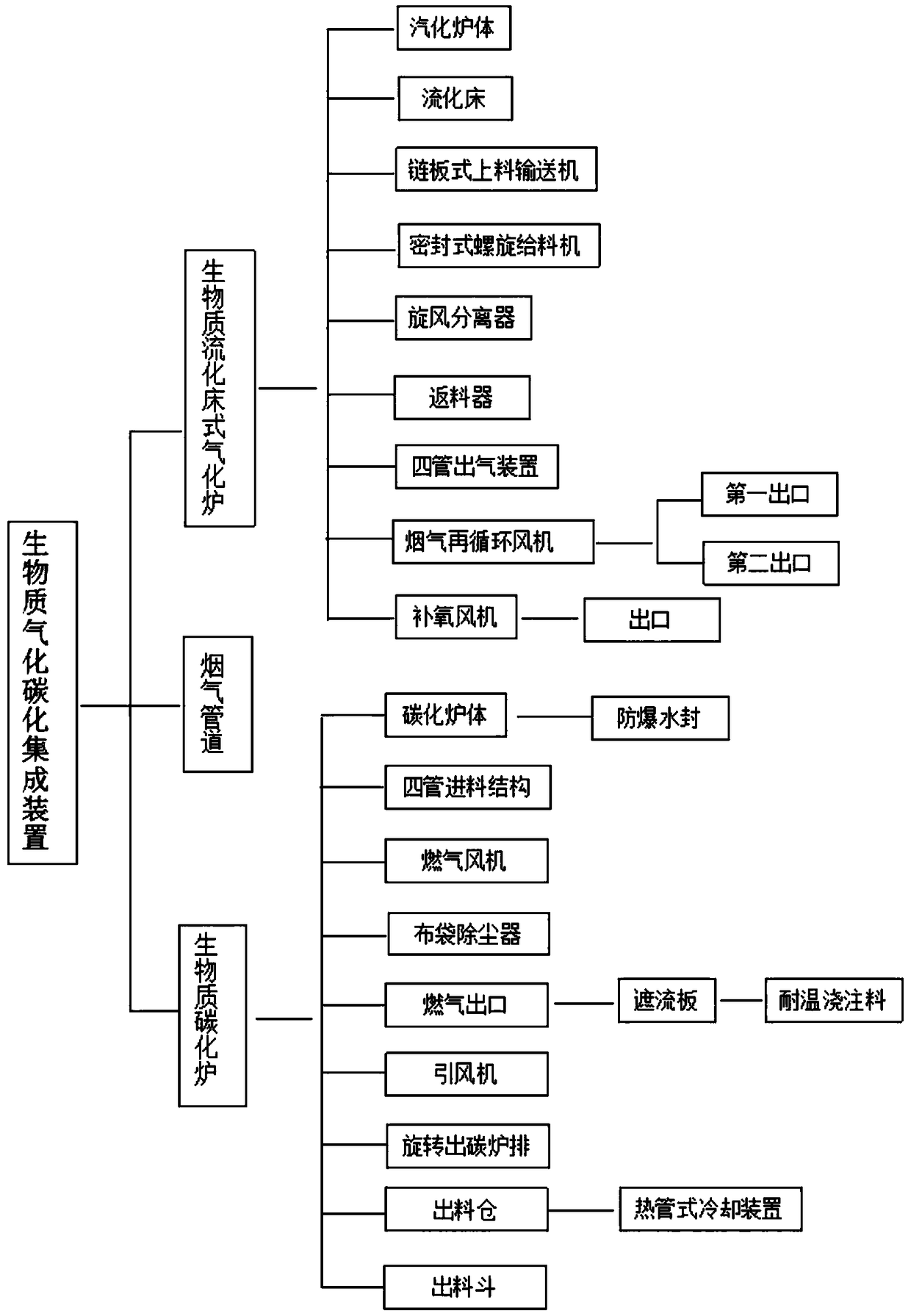

[0029] Example: complete combustion of biomass raw materials in a fluidized bed to generate high-temperature flue gas. Due to the low melting point of the biomass raw material ash, it is necessary to effectively control the combustion temperature, control the amount of oxygen entering the furnace, and at the same time meet a certain fluidization air volume and wind speed. Therefore, the flue gas recirculation technology is adopted to mix the extracted high-temperature flue gas at the outlet with air and use it as fluidizing air to control the amount of oxygen while meeting the air volume required for fluidization. In order to solve the problem of dust in the flue gas entering the carbonization furnace, a cyclone dust collector and a return device are added at the outlet of the fluidized bed gasification furnace, and the incompletely burned materials are separated by the cyclone separator and returned to the furnace for secondary combustion. To achieve the purpose of complete c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com