Vertical type gradient continuous sintering machine

A sintering machine and gradient technology, applied in furnace cooling, waste heat treatment, furnace control devices, etc., to achieve high energy utilization, less smoke and dust, and compact equipment design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

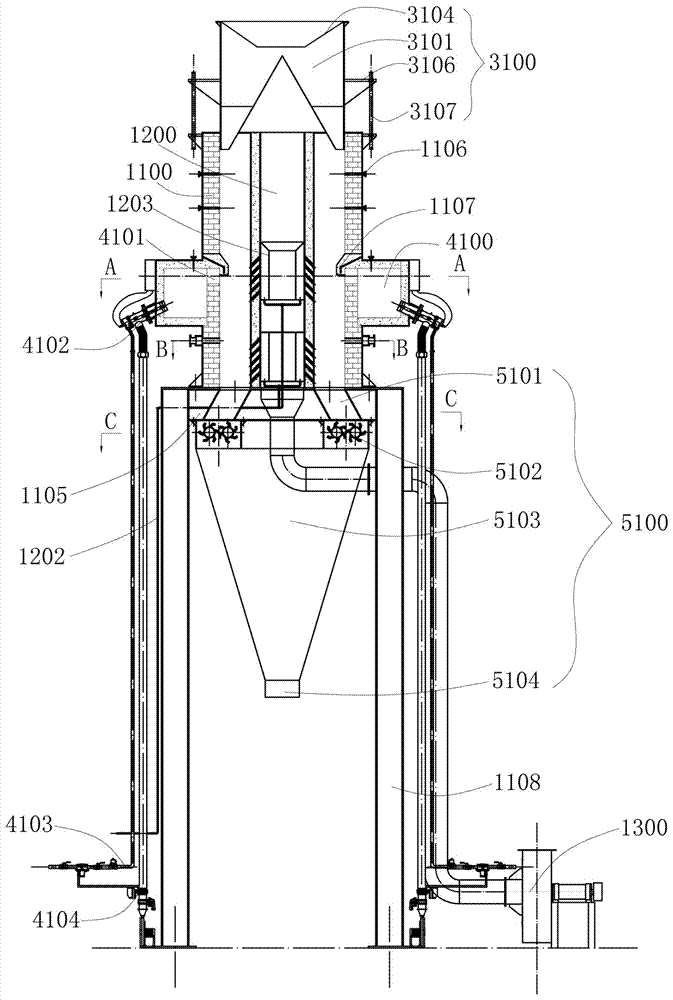

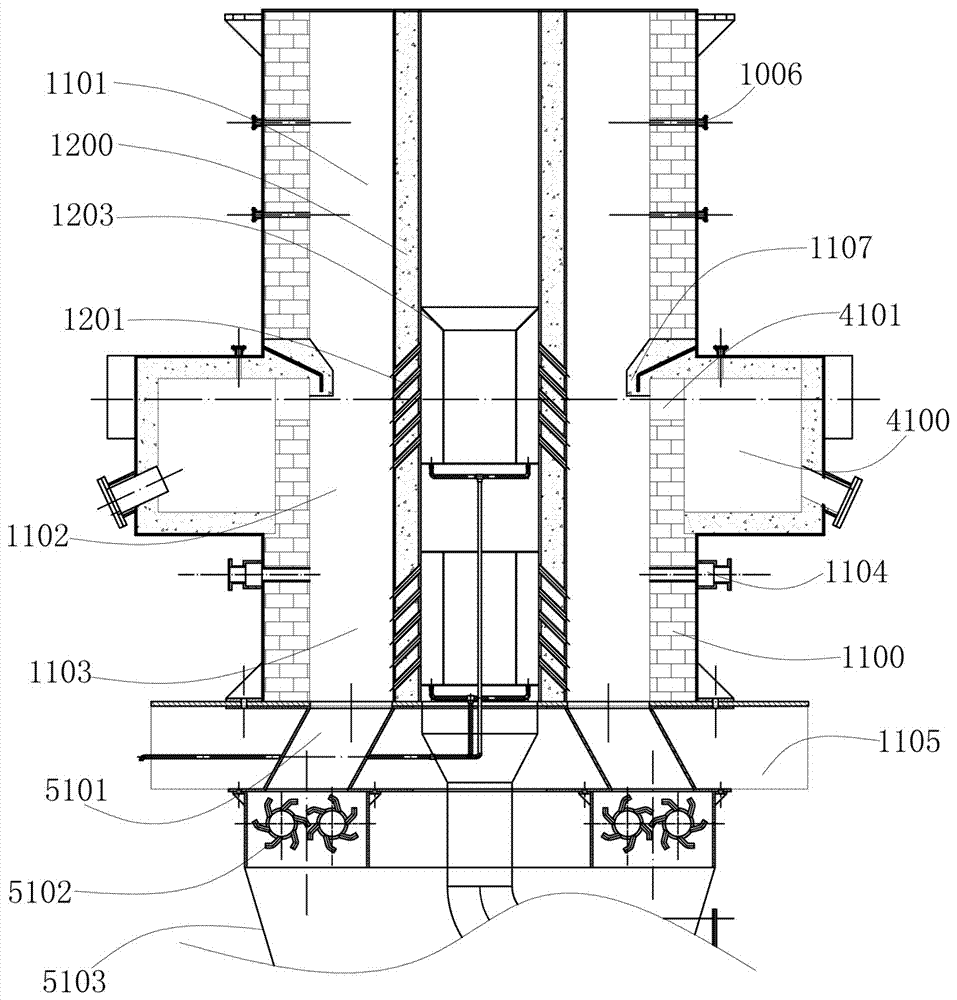

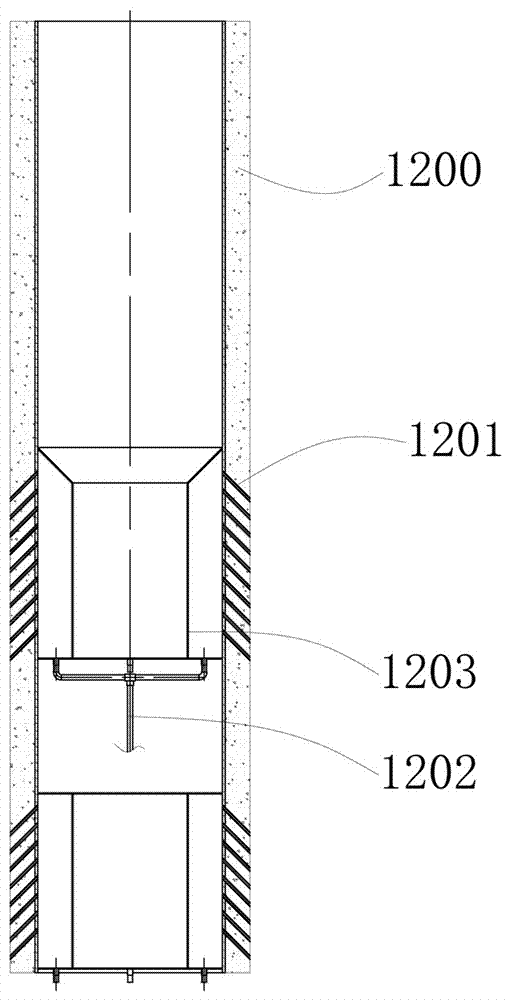

[0030] see Figure 1-Figure 8 , a vertical gradient continuous sintering machine of the present invention, including a furnace body 1100, an inner core tube 1200, a feed bin 3100, a combustion chamber 4100, and a discharge assembly 5100 arranged at the bottom of the furnace body 1100 and a The external air holes 1104 on the side wall, temperature sensors 1106 are evenly distributed on the furnace body 1100 and the combustion chamber 4100, and the inner wall of the furnace body 1100 corresponding to the combustion chamber 4100 is provided with a material guide eaves 1107 to prevent materials from entering the combustion chamber 4100.

[0031] A sintering chamber is formed between the furnace body 1100 and the inner core tube 1200, and the sintering chamber is arranged in turn as a preheating and drying area 1101, a sintering area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com