Waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology

A technology of low temperature and atmospheric pressure, production equipment, applied in the direction of sustainable manufacturing/processing, products, chemical industry, etc., can solve the problems of high cost, difficult to handle cracking products, low degree of automation control, etc., to achieve optimal configuration and automation degree, improve the effect of oil and gas purification, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

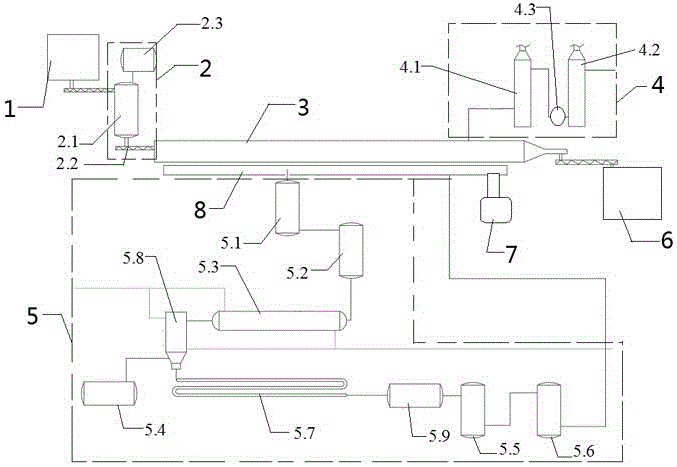

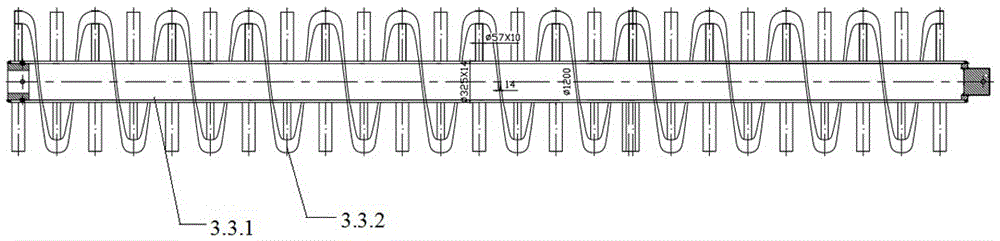

[0029] combined with Figure 1-4 , to further describe the present invention:

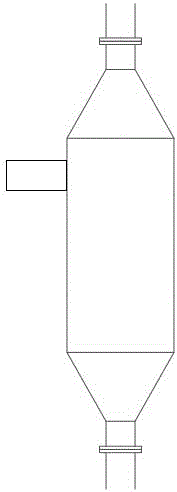

[0030]A low-temperature and normal-pressure continuous thermal cracking production device for waste tires, the technical solution of which is: comprising a pretreatment unit 1 connected in sequence, a conveying and loading unit 2, a thermal cracking unit 3, and a desulfurization atomization treatment unit respectively connected to the thermal cracking unit 3 Unit 4, oil and gas purification condensing unit 5, carbon black deep processing unit 6, cracking furnace heating unit 8; the pretreatment unit 1 is mainly connected from front to back with an automatic cutting machine, a crusher, a mill, a dryer, a magnetic Composed of iron remover, the terminal outlet of pretreatment unit 1 is connected to conveying and feeding unit 2, and conveying and feeding unit 2 is mainly composed of mixing tank 2.1, conveying device 2.2 and catalytic liquid adding tank 2.3, and the mixing tank 2.1 is connected with cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com