Heat accumulating type metal honeycomb gas electronic waste pyrolysis device and pyrolysis method

A technology of metal honeycomb and electronic waste, which is applied in special forms of dry distillation, indirect heating dry distillation, petroleum industry, etc. It can solve the problems of complex process, inability to realize continuous feeding and discharging, low efficiency of pyrolysis method, etc., and achieve uniform temperature and stable combustion , the effect of high combustion efficiency

Pending Publication Date: 2017-03-08

SHENWU TECH GRP CO LTD

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned device uses the hot air exchanger directly arranged at the outlet of the combustion oxidizer to intercept part of the high-temperature heat energy in the combustion flue gas of electronic waste to produce primary and secondary hot air above 600°C and return it to the melting combustion and oxidation combustion of electronic waste. This kind of pyrolysis method has low efficiency, complex process, and also has the problem that continuous feeding and discharging cannot be realized.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

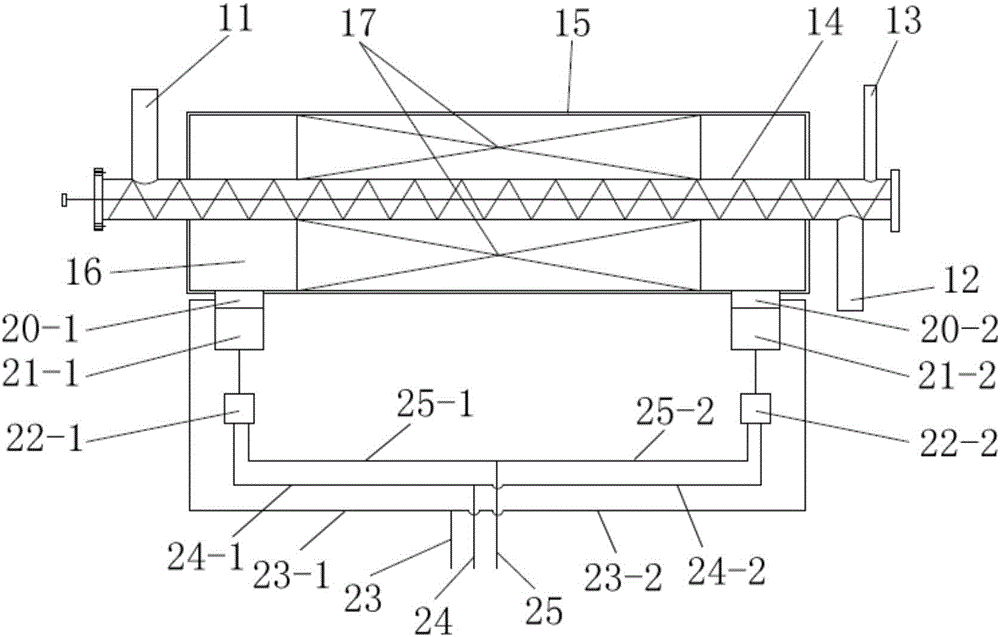

[0049] The regenerative gas heating system uses natural gas as fuel, and the natural gas volume is 2Nm 3 / h, the air volume is 22Nm 3 / h, electronic waste materials (circuit boards, wires, keyboards, etc.) 0.286Nm for oil and gas 3 / h, realizes continuous feeding and discharging of materials, and during the pyrolysis process, the temperature is continuously maintained at 600°C-700°C, and the heat source is very stable.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

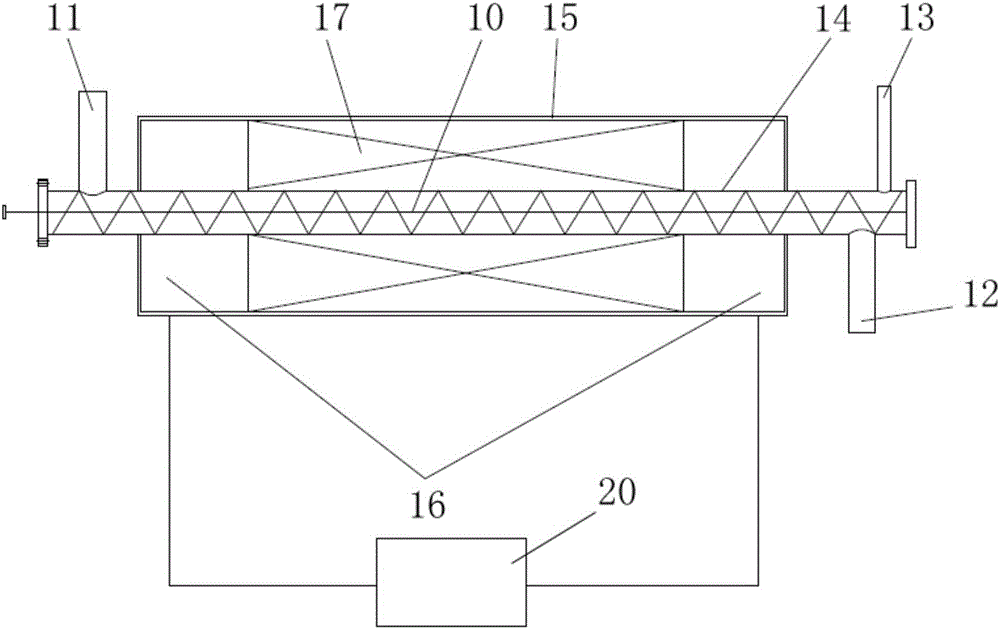

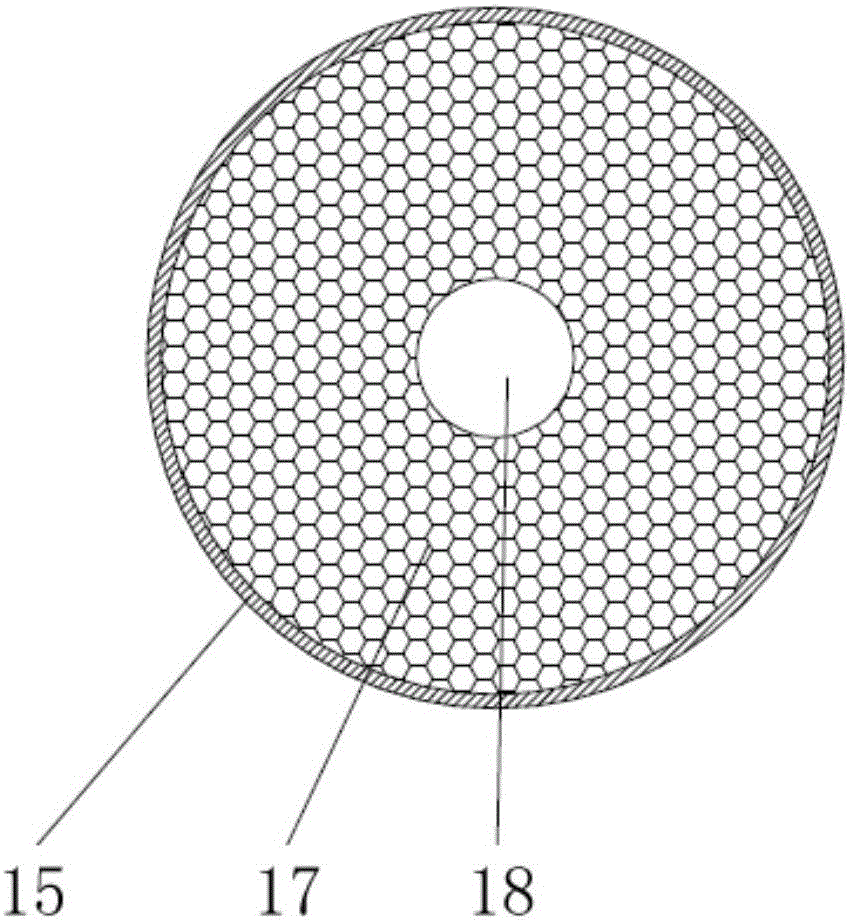

The invention discloses a heat accumulating type metal honeycomb gas electronic waste pyrolysis device. The heat accumulating type metal honeycomb gas electronic waste pyrolysis device comprises an electronic waste pyrolysis reactor and a heat accumulating type gas heating system. The electronic waste pyrolysis reactor comprises a reactor shell and a material pyrolysis assembly. The material pyrolysis assembly crosses the reaction shell. The heat accumulating type gas heating system comprises a metal honeycomb, a heat accumulating type combustion device and a flue gas channel. The flue gas channel is a closed space formed between the reaction shell and the material pyrolysis assembly in a matched mode, the flue gas channel is communicated with the heat accumulating type combustion device, the metal honeycomb is arranged in the flue gas channel, and the material pyrolysis assembly crosses the metal honeycomb. The invention further discloses a device for pyrolysis of electronic waste through the pyrolysis device. The method includes the two steps that a spiral shell is heated through the heat accumulating type gas heating system, and material pyrolysis is carried out. By means of the pyrolysis device and method, continuous material inflow and outflow can be achieved, the heat source stability is good, the pyrolysis process is simple, and the pyrolysis efficiency is high.

Description

technical field [0001] The invention belongs to the technical field of garbage pyrolysis, and in particular relates to a thermal storage type metal honeycomb gas-fired electronic waste pyrolysis device and a pyrolysis method. Background technique [0002] In recent years, all kinds of electronic products are changing with each passing day, and the new and old replacements are getting faster and faster, and the resulting electronic waste is increasing exponentially. The heavy metal elements contained in it will seriously pollute the environment. If electronic waste is not handled properly, it will produce toxic and harmful gases such as dioxin, causing secondary pollution. At present, the processing methods for electronic circuit boards mainly include mechanical physical methods, metallurgical extraction methods, biological treatment methods, and pyrolysis methods, among which mechanical physical methods, metallurgical extraction methods, and biological treatment methods main...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10B53/00C10B47/18C10B47/44

CPCC10B53/00C10B47/18C10B47/44

Inventor 韩希强王宁石为华王志军钟贵全王东方吴道洪

Owner SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com