Optical cable for connection of 3G equipment

A technology for equipment connection and optical cable, applied in the direction of fiber mechanical structure, etc., can solve the problems of difficult bending and laying, high hardness, inconvenient optical cable, etc., to achieve the effect of large transmission capacity, good bending performance, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

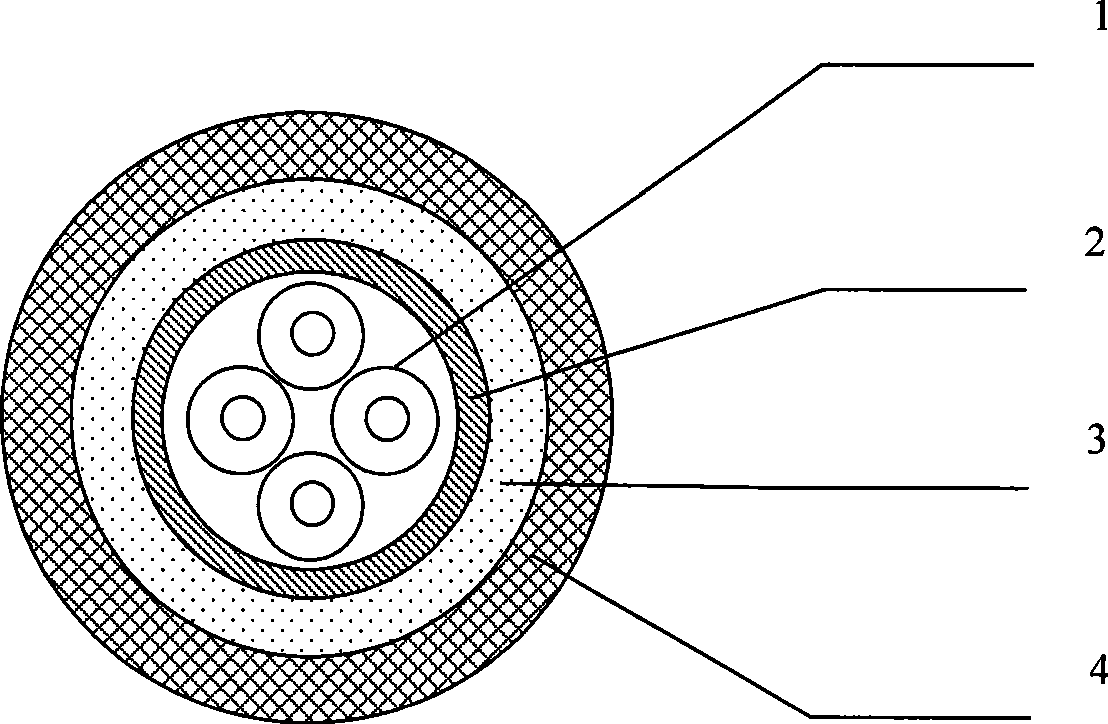

[0032] Two tight-buffered optical fiber sub-unit cables 1 are placed in a loose tube 2, surrounded by a reinforcement layer 3, and the outermost flame-retardant outer sheath 4 forms an optical cable structure for 3G equipment connection, and the entire optical cable is a fully dry structure .

[0033] In the above structure, the material of the tight tube is polyvinyl chloride, the material of the loose tube is polyvinyl chloride, the material of the reinforcement layer is glass fiber, and the material of the outer sheath is polyvinyl chloride.

Embodiment 2

[0035] Four tight-buffered optical fiber sub-unit cables 1 are placed in a loose tube 2, surrounded by a layer of strength members 3, and the outermost layer of flame-retardant outer sheath 4 forms an optical cable structure for 3G equipment connection. The entire optical cable is a fully dry structure .

[0036] In the above structure, the material of the tight tube is low-smoke halogen-free plastic LSZH material, the material of the loose tube is low-smoke halogen-free plastic LSZH material, the material of the reinforcement layer is aramid fiber, and the material of the outer sheath is polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com