Sole formula and production process thereof

A production process and formula technology, applied in the field of sole formulation and its production process, can solve the problems of non-slip resistance, wear resistance, low temperature resistance and muteness of the sole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

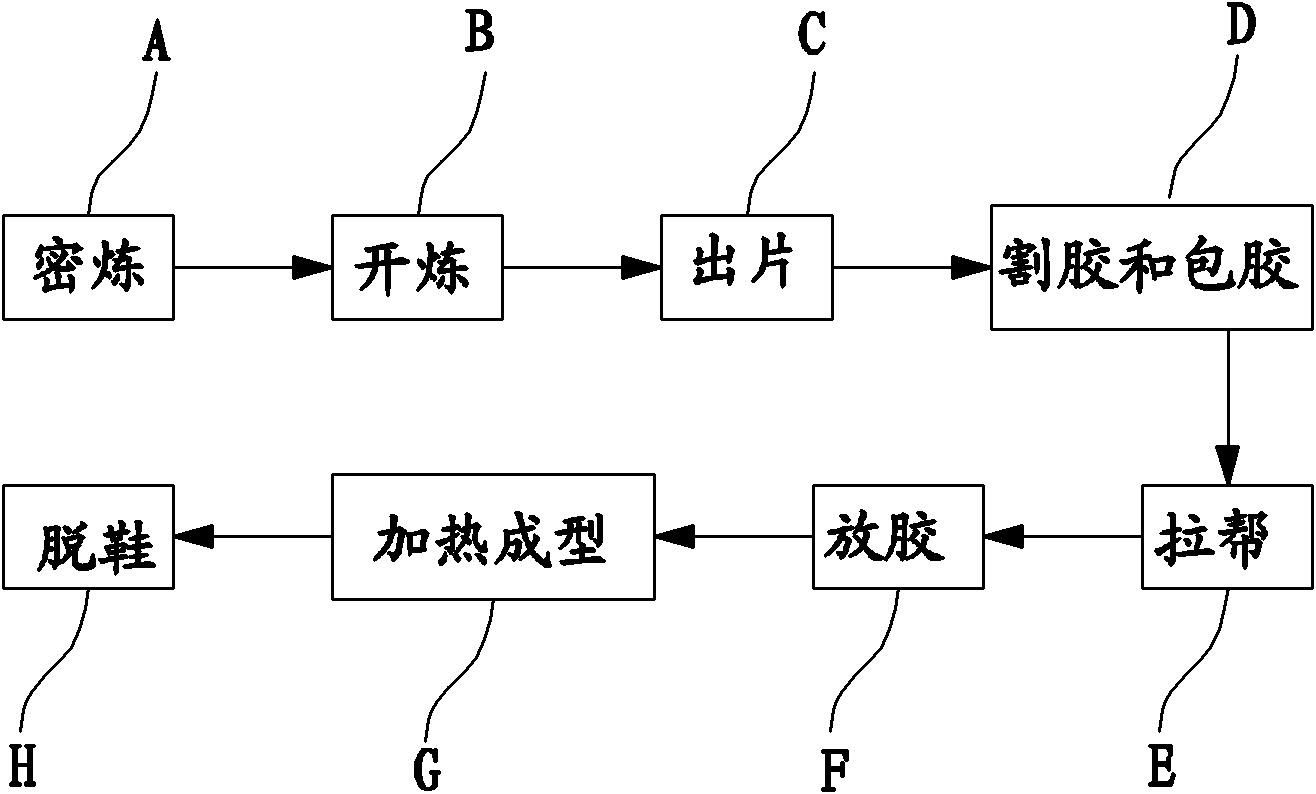

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0027] The shoe sole that the present invention relates to, its raw material formula comprises large material, small material and additive, and it is respectively following components:

[0028] The aniseed material includes natural rubber: 3-5 parts, isoprene rubber: 10-13.8 parts, talcum powder: 5-7 parts, nano-ointment: 10-14.5 parts, white carbon black: 3-5.6 parts;

[0029] The small material includes zinc carbonate: 0.94-1.2 parts; flow aid: 0.1-0.3 parts; DCP: 0.01-0.03 parts; anti-aging agent: 0.188-0.276; protective wax: 0.125-0.25;

[0030] The additives include p-toluenesulfonyl: 0.05-0.08 parts; sulfur: 0.1-0.2 parts; foaming agent: 0.025-0.05 parts.

[0031] Wherein, the foaming agent may be selected from one of azodicarbonamide, azoisobutyronitrile or p-toluenesulfonyl hydrazide. The flow aid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com