A fruit and vegetable washing and draining conveyor

A fruit and vegetable cleaning and conveyor technology, applied in the fields of application, food science, food processing, etc., can solve the problems of high cost, single function, complicated operation, etc., and achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

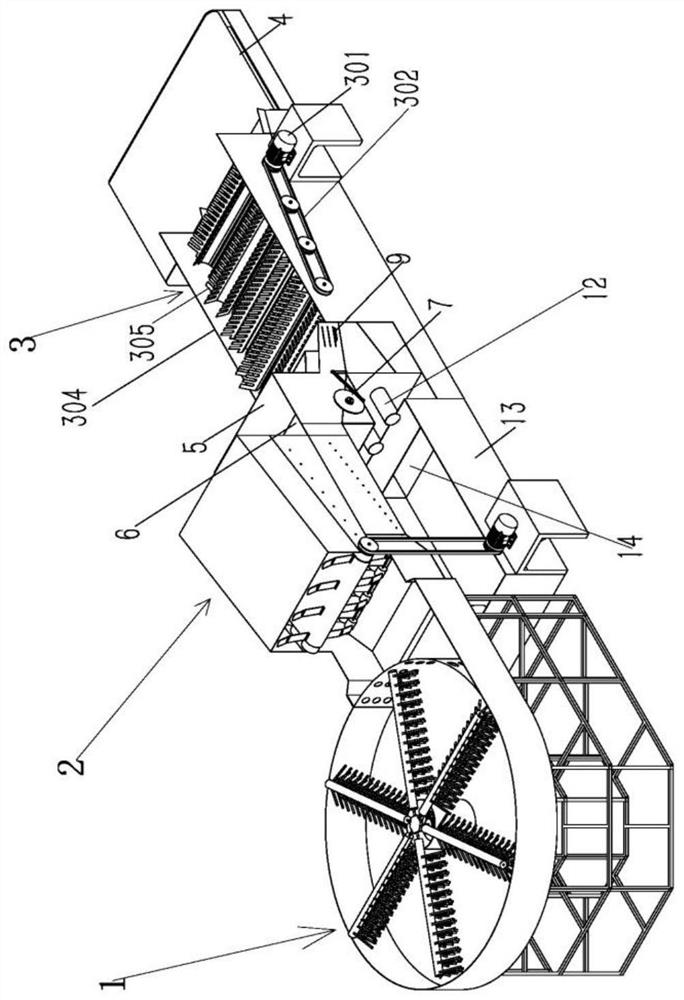

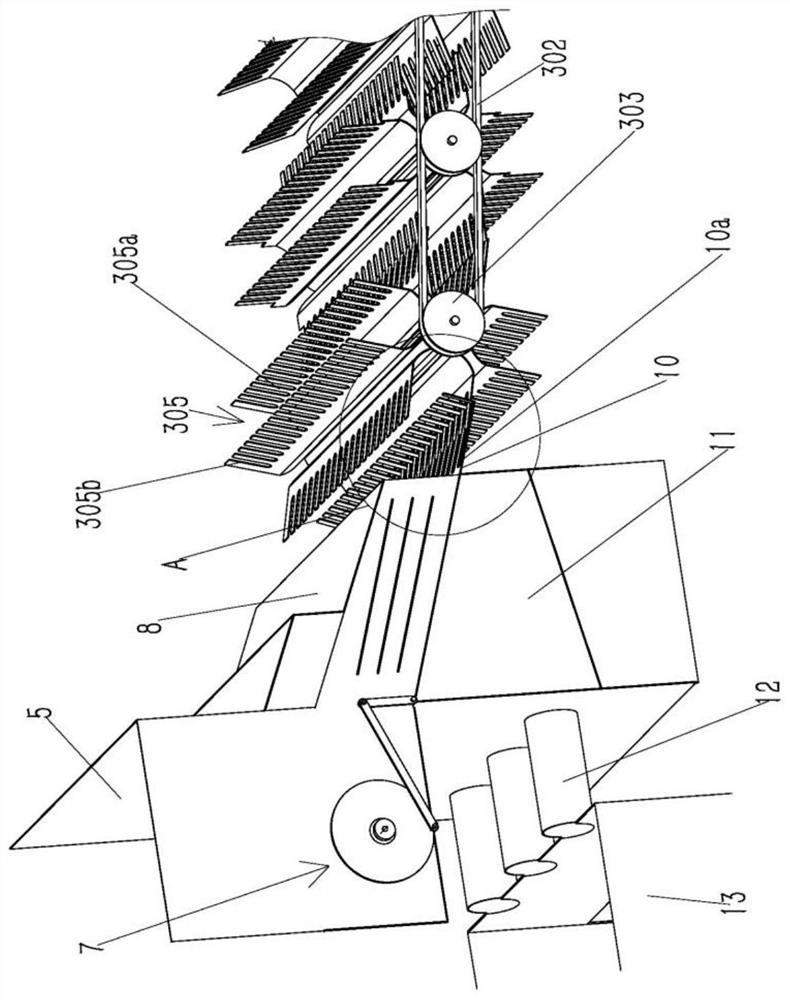

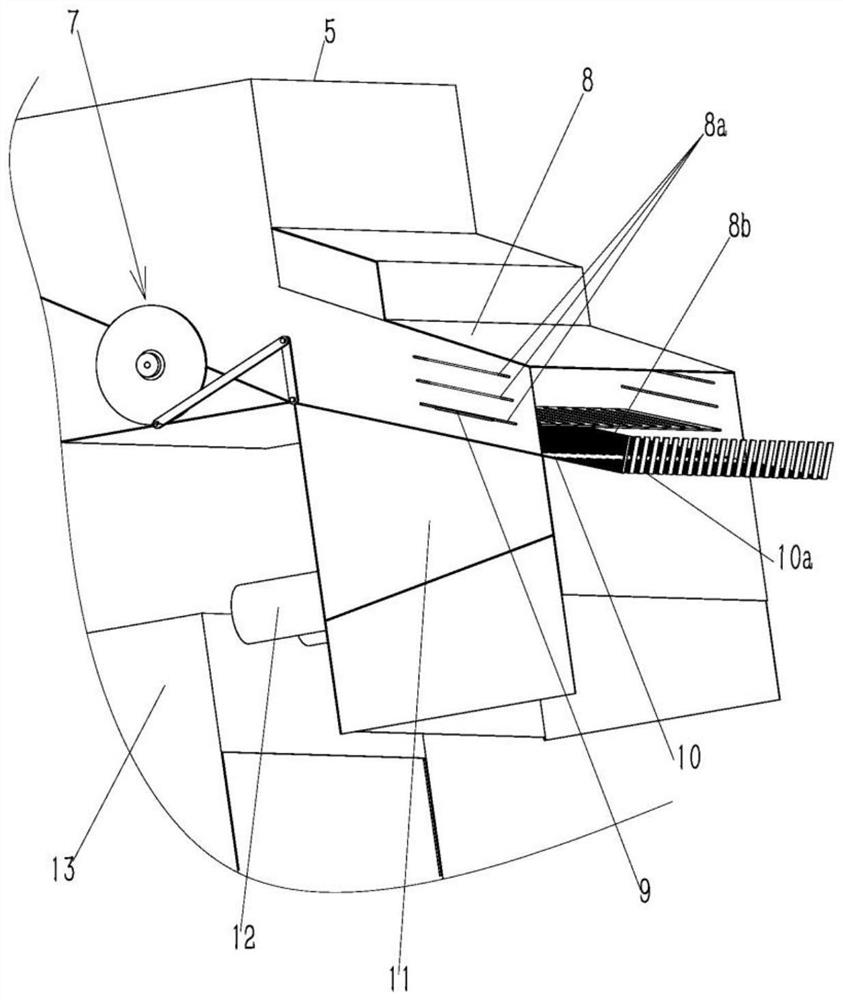

[0032] like Figure 1-7 As shown, a fruit and vegetable washing and draining conveyor includes a rough washing part 1, a fine washing part 2, a draining part 3, and a transport conveyor belt 4 in sequence according to the transport direction. The fruits and vegetables need to be cleaned by the rough washing part 1 and the fine washing part 2 and then transferred to the draining part 3, and most of the residual water in the fruits and vegetables is drained by the draining part 3, and then transferred to the transfer conveyor belt 4 for transfer to the container. the location of the box or package.

[0033] The above-mentioned draining part 3 comprises a draining box 306 with an open structure at the top, extending as a rectangular structure along the transporting direction, and a number of grid rolling racks 305 arranged horizontally and rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com