Sterile humidifying liquid adding vehicle

A technology for humidifying liquid and humidifying bottle, applied in the field of medical devices, can solve the problems of affecting the treatment effect, increasing the risk of hospital feeling, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

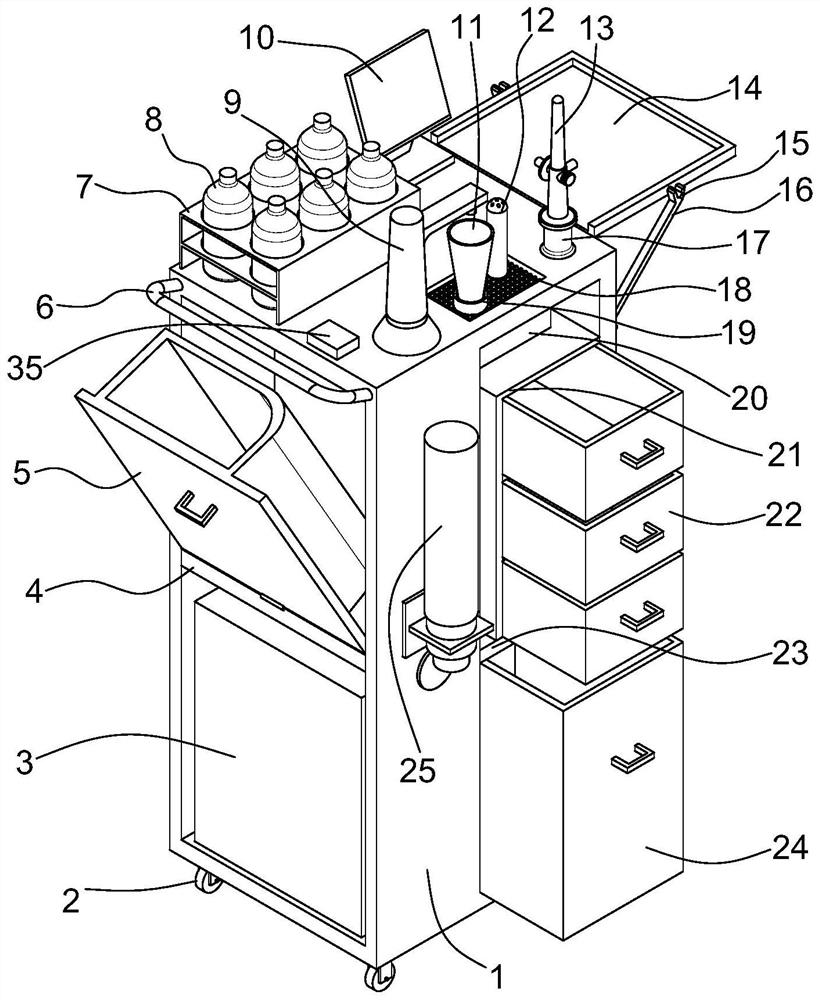

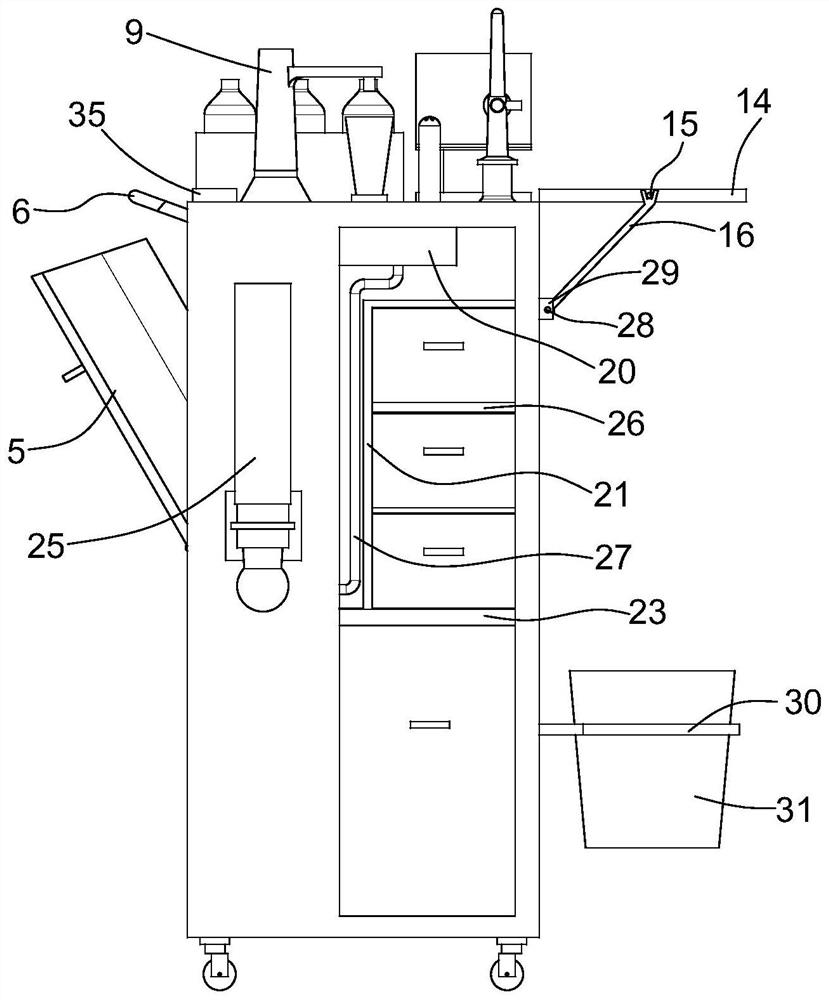

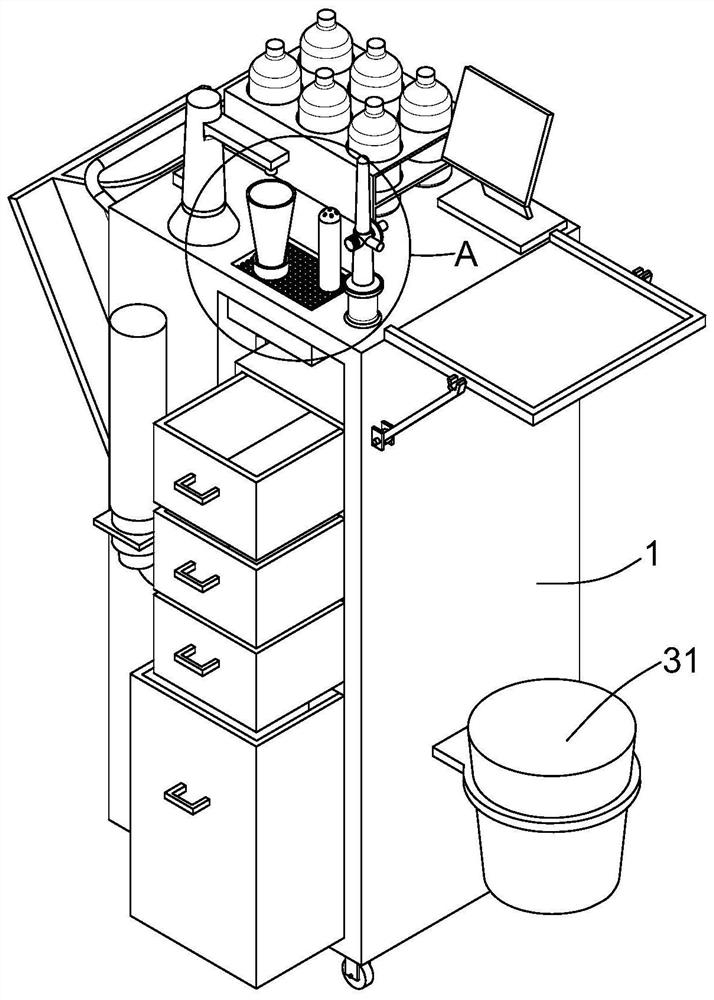

[0034] Please refer to Figure 1 to Figure 5 , a sterile humidification liquid filling vehicle, including such as figure 1The shown hollow cuboid car body 1 is provided with a vertical plate 32 that divides it into a recovery area and a storage area in the horizontal direction in the car body 1, and also includes a draining area 18 arranged on the top of the car body 1, adding Fluid components and auxiliary components. The recycling area is provided with a first partition 4 longitudinally dividing it into a dry matter part and a waste liquid part, and the draining area 18 communicates with the waste liquid part. In this embodiment, the draining area 18 is used to dump the remaining humidification liquid in the used humidification bottle 11, and the liquid filling component is used to fill the newly replaced humidification bottle 11 with sterile humidification liquid, and the auxiliary components are used For placing the accessories of the buoy type oxygen inhaler, the dry pa...

Embodiment 2

[0045] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

[0046] In this example, if Figure 4 and Figure 7 As shown, the bottom of the drain tank 181 is provided with several grooves 183. In this embodiment, the grooves 183 are U-shaped grooves. In other embodiments, the grooves 183 can be V-shaped grooves or arc grooves. A plurality of evenly distributed first drain holes 182 are disposed through the bottom of the groove 183 . The groove 183 is convenient for fully emptying the waste wetting liquid from the bottom of the draining tank 181. The opening of the groove 183 reduces the planar area of the bottom of the draining tank 181, thereby making the remaining waste wetted at the bottom of the draining tank 181 The reduced liquid volume facilitates the cleaning of the drain tank 181 and reduces the risk of cross-infection.

Embodiment 3

[0048] This embodiment is a further improvement on Embodiment 2, and repeated content will not be repeated here.

[0049] Such as Figure 4 and Figure 8 As shown, several grooves 183 are distributed in parallel, and a protrusion 184 is formed between two adjacent grooves 183 , and the top of the protrusion 184 is in the shape of an outwardly convex arc. In this embodiment, the convex portion 184 in the shape of an arc makes the plane area of the bottom of the draining tank 181 zero, and when the waste humidification liquid is poured into the draining tank 181, no waste will appear at the bottom of the draining tank 181. Moisturizing fluid remains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com