Device and method for efficiently producing stable ozone (O3) ointment

A production device and ozone technology, applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of long time, low utilization rate of ozone and oxygen, unstable ozone content, etc., to achieve enhanced stability, Good bactericidal effect, increase the effect of low-speed agitator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

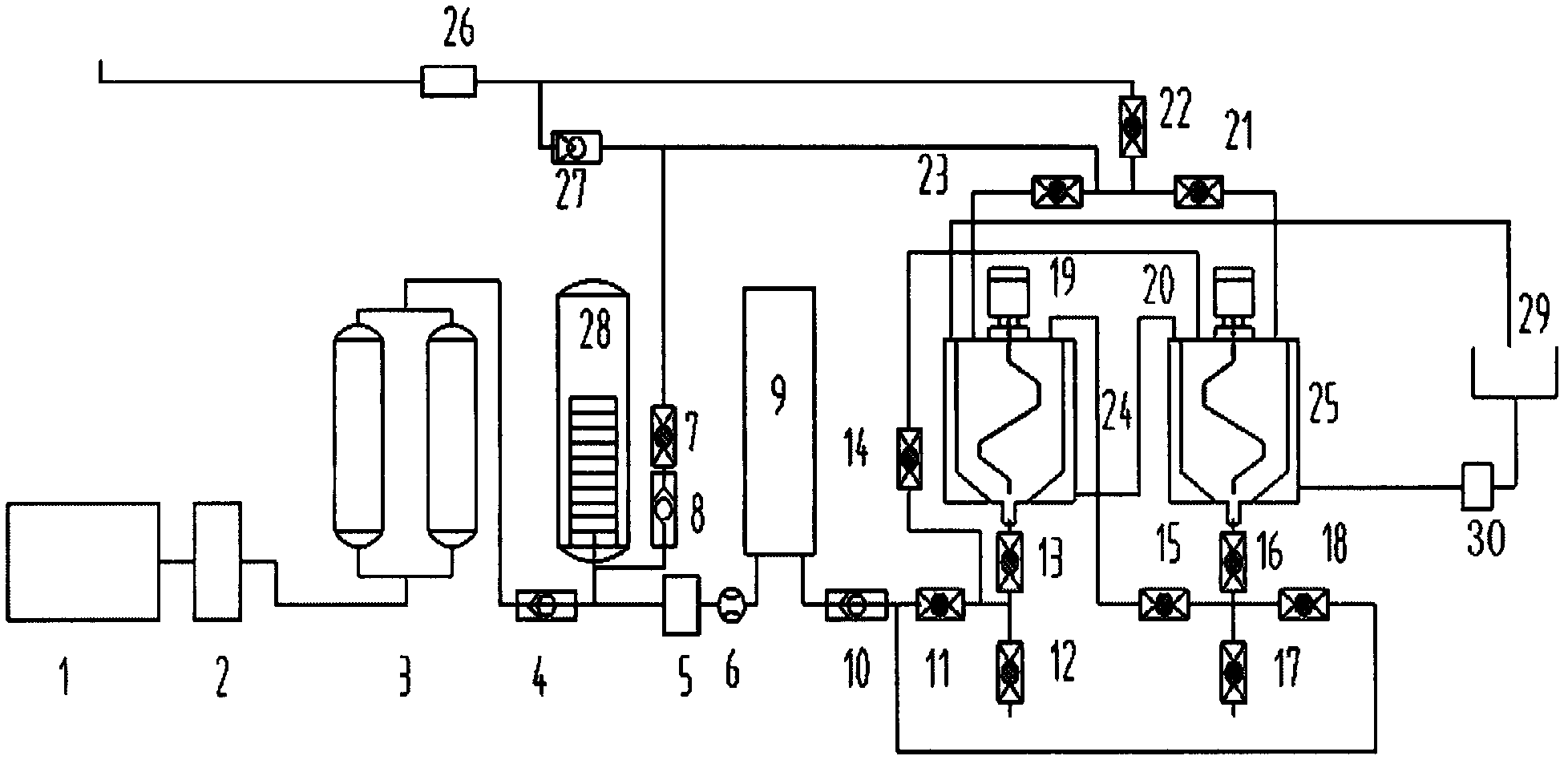

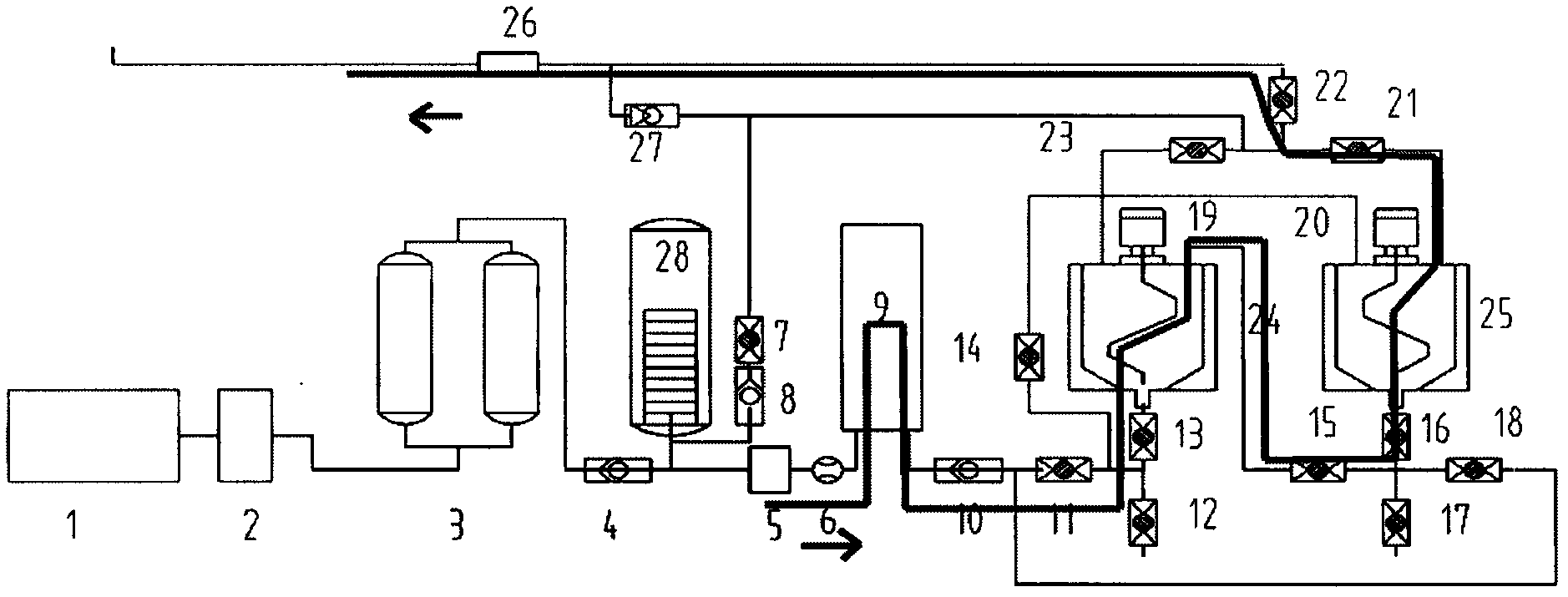

[0023] refer to figure 1 , an efficient production of stable ozone (O 3 ) Ointment production device and method.

[0024] One: close the working state switching valves 12, 17, 18, 23, 14, open the working state switching valves 11, 13, 15, 16, 21, add vegetable oil (such as olive oil, coconut oil, sunflower oil, etc.) Reactor No. 2 and Reactor No. 2. Open the deflation valve 22 and start the cooling water pump 21.

[0025] Two: 10 minutes after turning on the air dryer, turn on the oil-free air compressor 1, the air pump 5, the ozone generator 9, the agitator motor 19, 20, (see figure 2 )

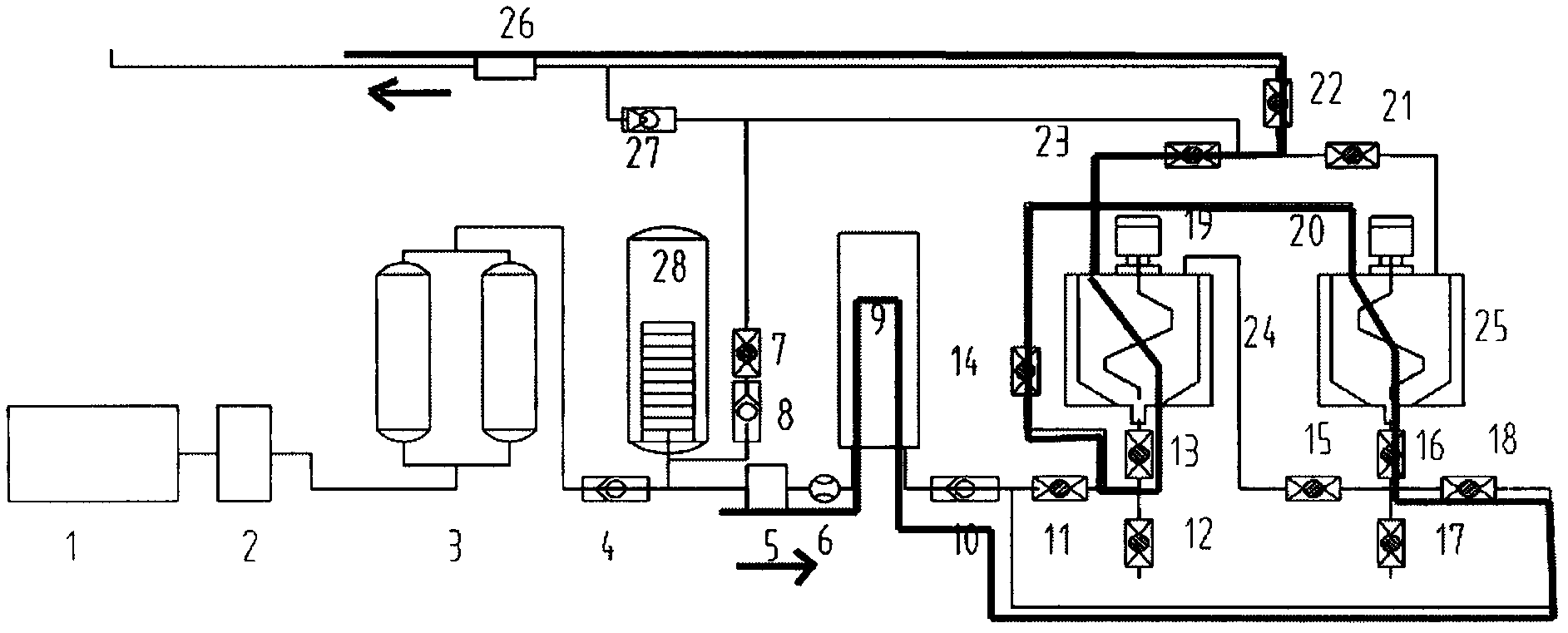

[0026] Three: After 20 minutes, open the ball valve 7 and close the deflation valve 22. (see working status Figure 4 )

[0027] Four: After the deflation valve 22 is closed, the residual gas passes through the oxygen recovery check valve 8 and is recycled into the air bag type gas storage tank 28 .

[0028] Five: Control the start and stop of the oil-free air compressor according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com