Preparation method of non-silicon defoaming agent

A technology of non-silicon defoamer and silicone oil, applied in the field of preparation of non-silicon defoamer, can solve the problems of insufficient chemical stability, slow defoaming speed, poor strong alkali resistance, etc., and achieve thermal stability and chemical stability. Good effect, low production cost, excellent defoaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for preparing the non-silicon defoamer in the present invention is as follows: first, add 24 parts of white mineral oil, 3 parts of white carbon black, 25 parts of polyether, and 24 parts of castor oil into a reaction kettle equipped with a stirrer, a motor and a heating system, 24 parts of polypropylene glycol, mixed evenly, and discharged after stirring for an hour, to obtain ointment.

[0019] Take 80 parts of the prepared ointment, add self-emulsifying silicone oil, 20 parts of phosphate ester, 5 parts of emulsifier XP-50, SP-80, stir well, then add 280 parts of water to make phase inversion, and the phase inversion is complete Then add 16 parts of thickener AT-70 to thicken and adjust the viscosity to 1500CS~2000CS, and then discharge and pack.

[0020] The white mineral oil in the raw material has a viscosity of 5CS; the white carbon black has a specific surface area (BET method) of 200±25m 2 / g, fumed silica with an average primary particle size of 13...

Embodiment 2~4

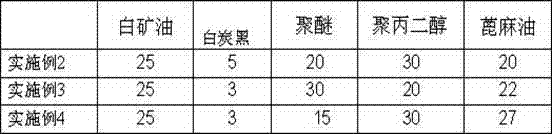

[0022] Compared with Example 1, the production process of Examples 2-4 is the same and will not be repeated. The proportioning, reaction time and temperature of each component in each embodiment are shown in Table 1 below.

[0023] Table 1 Case 2-4 Material ratio of ointment

[0024]

[0025] Table 2 Material Proportion of Case 2-4

[0026] Example 2 Example 3 Example 4 ointment 80 80 80 Self Milking Silicone Oil 20 10 5 Phosphate 20 30 35 Emulsifier XP-50 5 5 5 Emulsifier SP-80 5 5 5 Thickener AT-70 16 16 16 water 280 280 280

[0027] Performance of non-silicon defoamers;

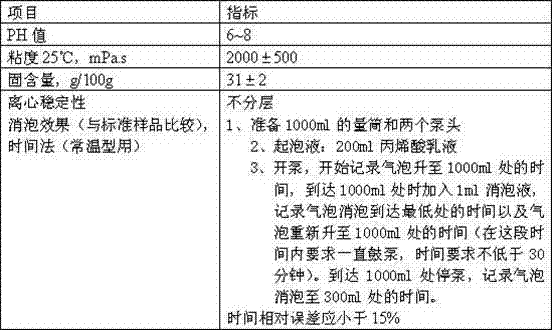

[0028] The product obtained in Example 1, the non-silicon defoamer, was tested according to the following standards, and the appearance was milky white and uniform liquid without mechanical impurities, and the physical and chemical properties were shown in Table 3;

[0029] Table 3 Physical and chemical properties

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com