High-intensity magnetic rubber

A magnetic rubber, high-strength technology, applied in the field of high-strength magnetic rubber and high-strength rubber, can solve the problems of low magnetic properties and low mechanical properties, and achieve the effect of good magnetic properties and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

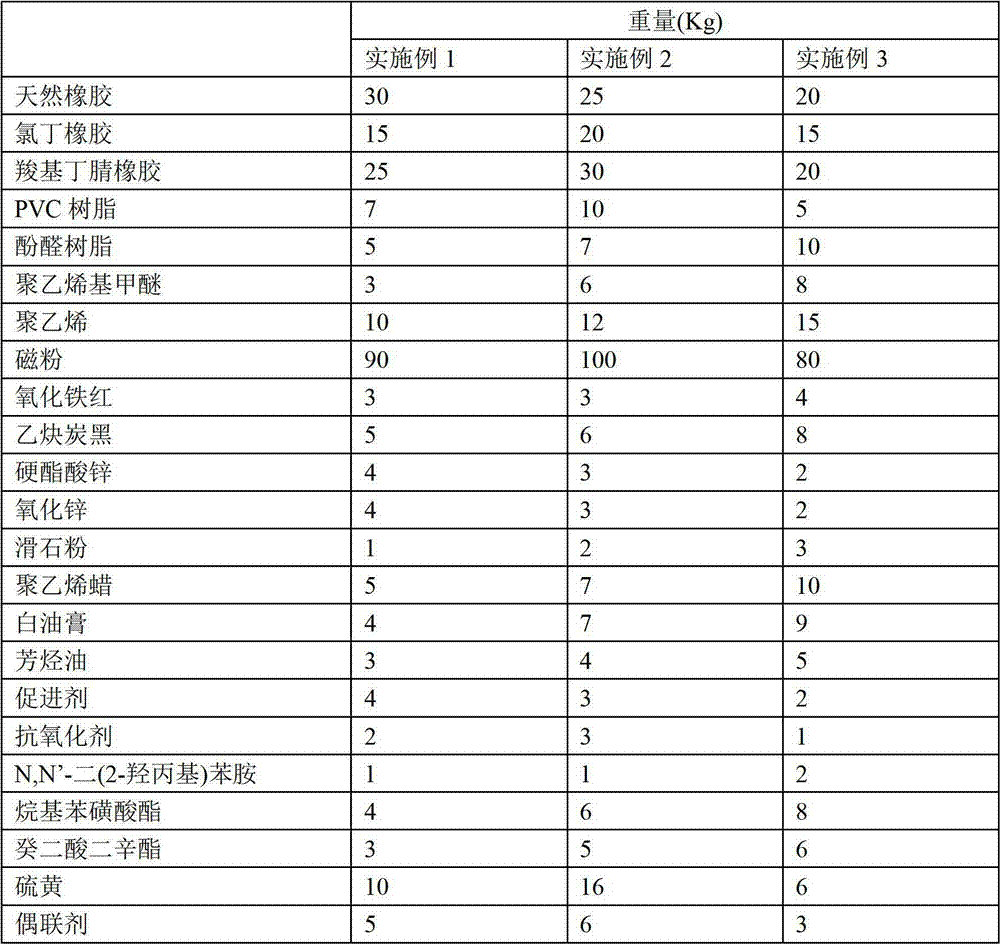

Examples

Embodiment 1

[0035] S1: Mix the rubber evenly, crush it, and mix it evenly with

[0036] S2: Add it to the rubber mixer, mix the rubber at a temperature of 170°C, and grind it into a paste block;

[0037] S3: Pour into the mold, cool and solidify;

[0038] S4: Magnetize under the conditions of a magnetic field strength of 400-600V and a frequency of 50-100Hz, and cut according to the required size.

Embodiment 2

[0040] The difference from Example 1 is that: the temperature in step S2 is 175°C; the magnetic field strength in step S4 is 500V, and the frequency is 75Hz.

Embodiment 3

[0042] The difference from Example 1 is that: the temperature in step S2 is 180°C; the magnetic field strength in step S4 is 600V, and the frequency is 100Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com