Optical fiber and cable factice spraying system adjusting spraying amount intelligently

An intelligent adjustment, optical fiber and cable technology, applied in the directions of light guide, optics, jetting device, etc., can solve the problems of difficulty in achieving the best, increasing the application amount, unfavorable production, etc., to improve the reliability and guarantee of yield and performance. Uniformity, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

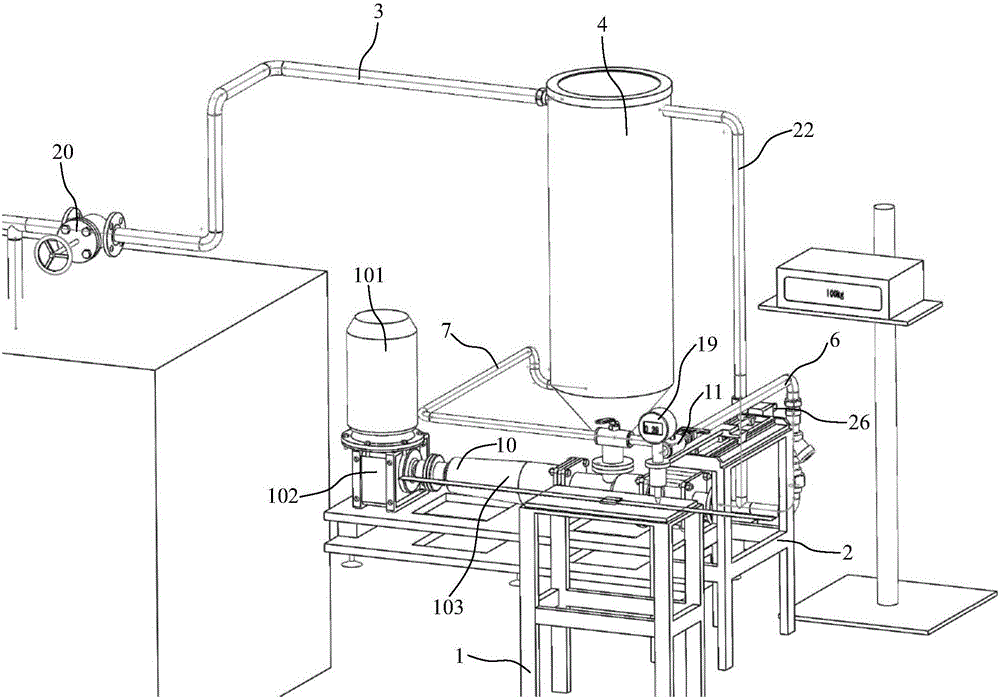

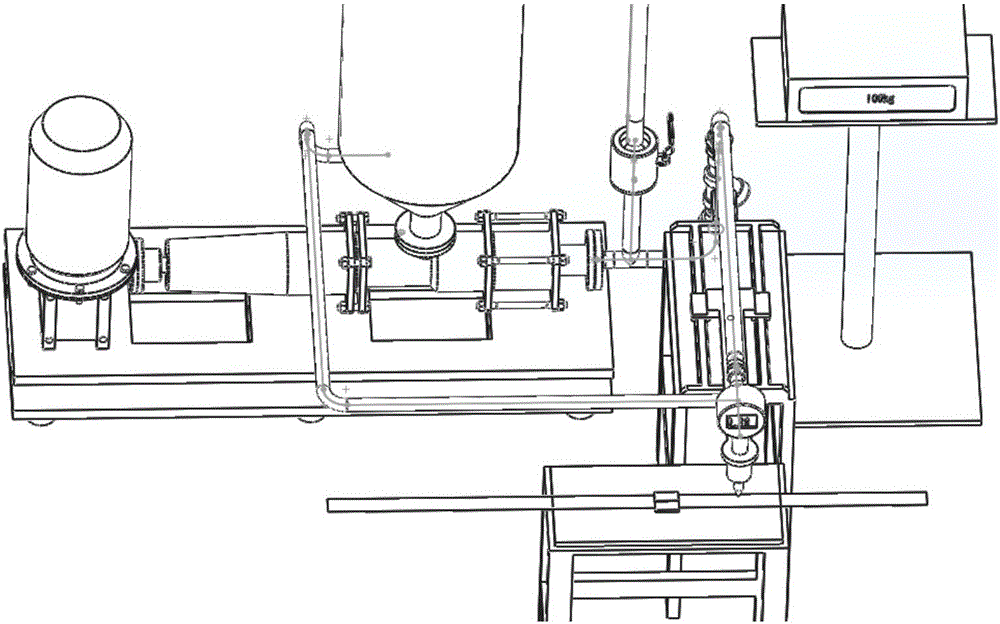

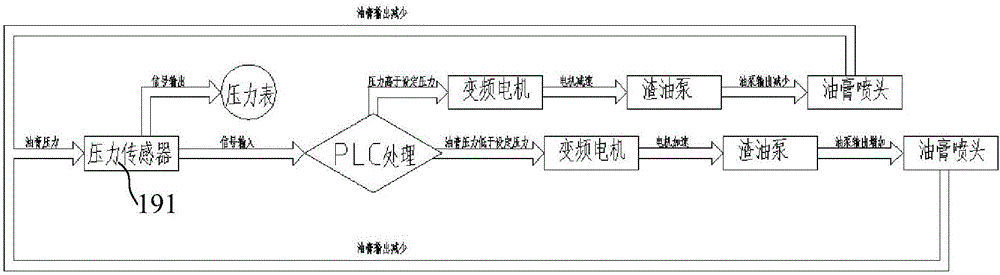

[0025] Embodiment 1: An optical fiber cable ointment spraying system that intelligently adjusts the amount of spraying, including a carrier 1, a support frame 2, an oil supply pipeline 3, an oil storage tank 4, an oil delivery pipe 6, a first oil return pipe 7, and an oil inlet pipe 8 , PLC control module 9, ointment pushing mechanism 10 and image recognition module 25, described image recognition module 25 is used for collecting metal strip and the ointment spray trajectory image information that is positioned at the metal strip surface;

[0026] The grease pushing mechanism 10 is connected to the first port of the three-way joint 11 through the oil delivery pipe 6, and the second port of the three-way joint 11 is connected to a spray head 12 through the oil inlet pipe 8, and the carrier 1 is located directly below the spray head 12 , the third port of the tee joint 11 is connected to the oil storage tank 4 through the first oil return pipe 7, and the upper surface of the supp...

Embodiment 2

[0031] Embodiment 2: An optical fiber cable ointment spraying system that intelligently adjusts the amount of spraying, including a carrier 1, a support frame 2, an oil supply pipeline 3, an oil storage tank 4, an oil delivery pipe 6, a first oil return pipe 7, and an oil inlet pipe 8 , PLC control module 9, ointment pushing mechanism 10 and image recognition module 25, described image recognition module 25 is used for collecting metal strip and the ointment spray trajectory image information that is positioned at the metal strip surface;

[0032] The grease pushing mechanism 10 is connected to the first port of the three-way joint 11 through the oil delivery pipe 6, and the second port of the three-way joint 11 is connected to a spray head 12 through the oil inlet pipe 8, and the carrier 1 is located directly below the spray head 12 , the third port of the tee joint 11 is connected to the oil storage tank 4 through the first oil return pipe 7, and the upper surface of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com