Wear-resisting protective factice for rail wheeltrack

A wheel-rail and railway technology, used in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of difficulty in forming a lubricating oil film, increase the number of oilings, and accelerate wheel-rail wear, etc. The effect of good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

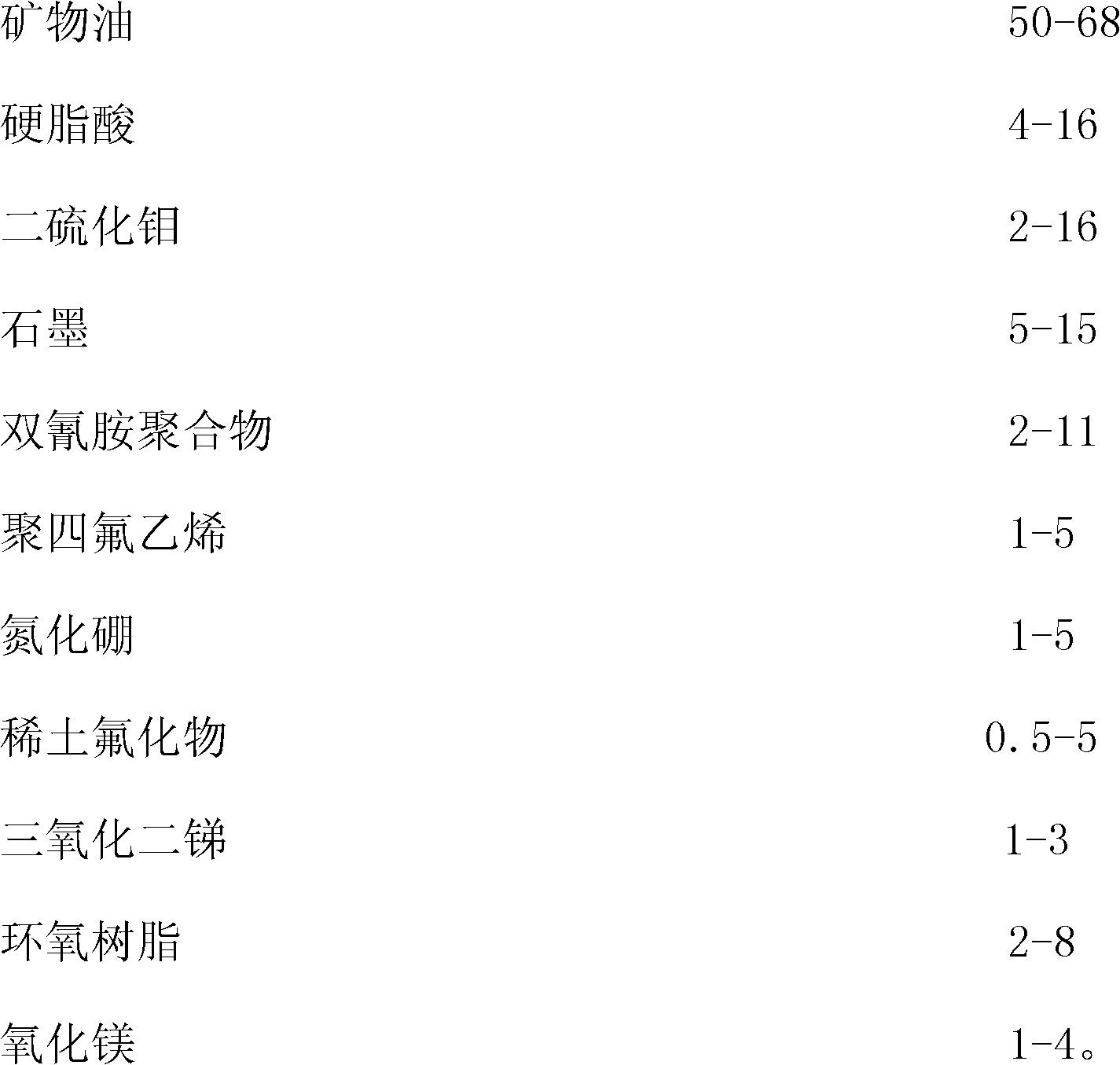

[0012] Wear-resistant protective ointment for railway wheels and rails, consisting of the following raw materials in parts by weight: mineral oil 50-68, stearic acid 4-16, molybdenum disulfide 2-16, graphite 5-15, dicyandiamide polymerization 2-11, polytetrafluoroethylene 1-5, boron nitride 1-5, rare earth fluoride 0.5-5, antimony trioxide 1-3, epoxy resin 2-8, magnesium oxide 1-4.

Embodiment 2

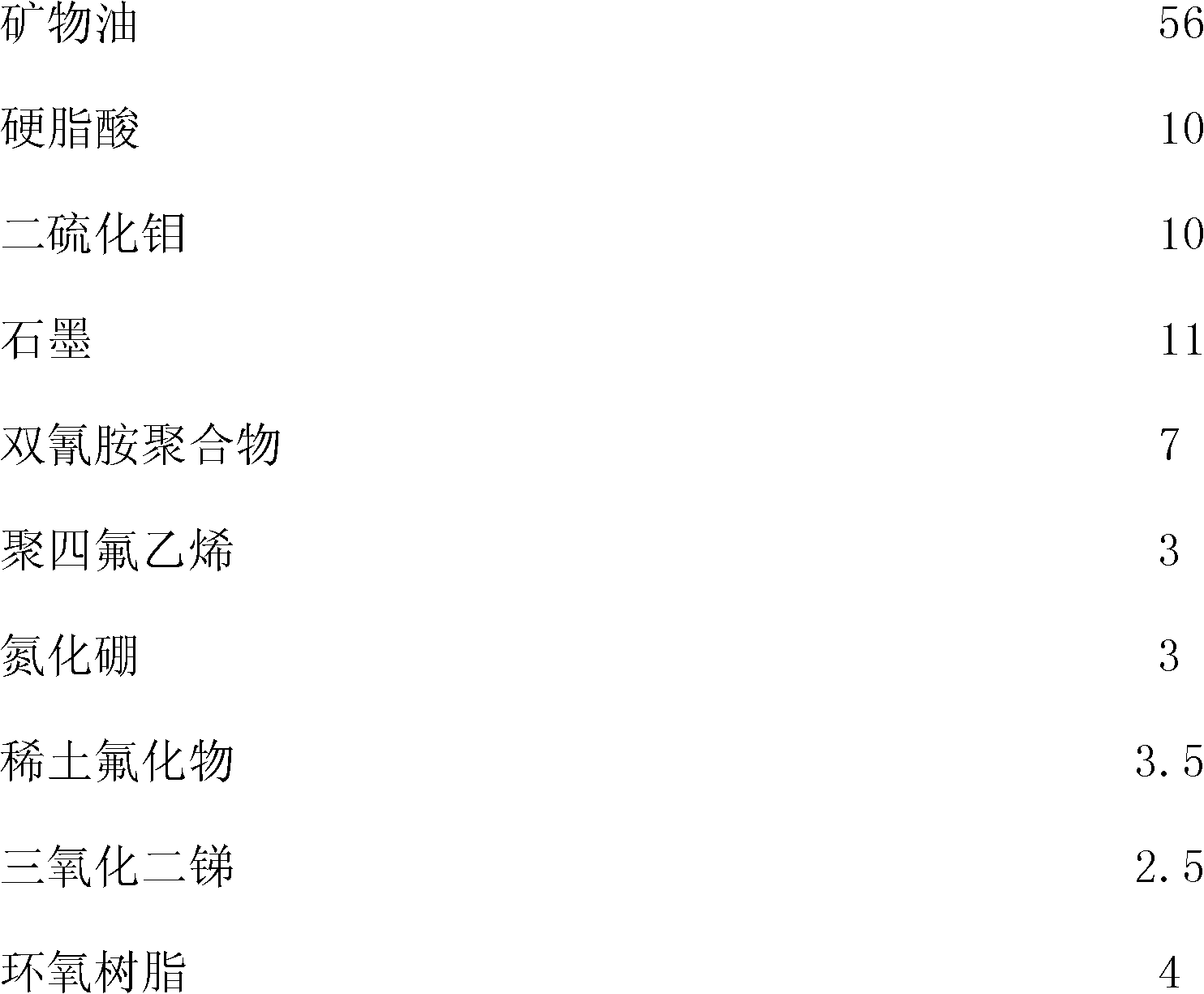

[0014] The wear-resistant ointment used for railway wheel rails is preferably composed of the following raw materials in parts by weight: mineral oil 56, stearic acid 10, molybdenum disulfide 10, graphite 11, dicyandiamide polymer 7, polytetrafluoroethylene 3, boron nitride 3, rare earth fluoride 3.5, antimony trioxide 2.5, epoxy resin 4, magnesium oxide 2.5.

[0015] The above mineral oil can be selected from gear oil, cylinder oil or machine oil, and the addition of magnesium oxide can increase the wear resistance of the ointment to more than 700 minutes, which has significant practical value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com