Dust removal purification device and method for crude coal tar

A purification device and technology for tar, applied in chemical instruments and methods, separation methods, tar processing and other directions, can solve the problems of low efficiency of dust removal and purification of crude coal tar, and achieve the effect of flexible device, stable and reliable operation, and no solvent loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

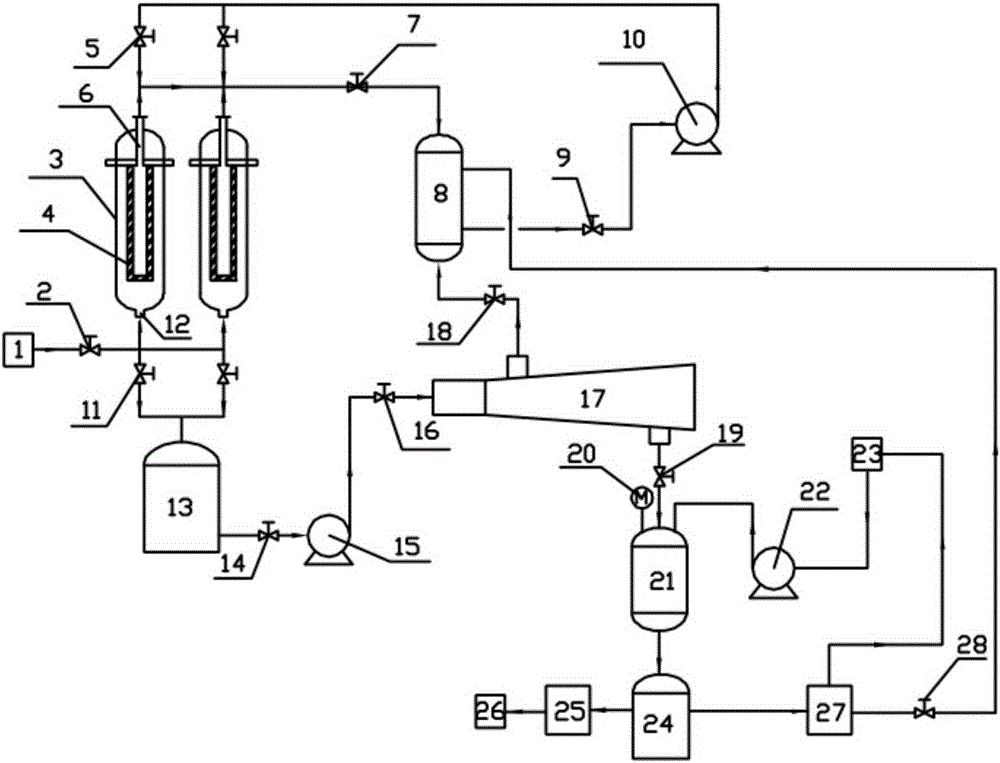

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] see figure 1 , the device of the present invention includes one or more parallel backwash filters 3 in which filter core 4 is installed, the crude coal tar 1 is communicated with the bottom inlet 12 of the backwash filter through the feed valve 2, and the filter core 4 inner cavity It communicates with the top outlet 6 of the backwash filter, and communicates with the purified tar tank 8 through the first outlet valve 7 of the purified oil, and the bottom of the backwash filter 3 communicates with the residual oil buffer tank 13 through the drain valve 11 to purify the tar The outlet of the tank 8 communicates with the inner cavity of the filter element 4 installed in the recoil filter 3 through the first recoil valve 9, the recoil pump 10 and the second recoil valve 5 in turn, and the outlet of the residual oil buffer tank 13 passes through the The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com