Patents

Literature

75 results about "Cup material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

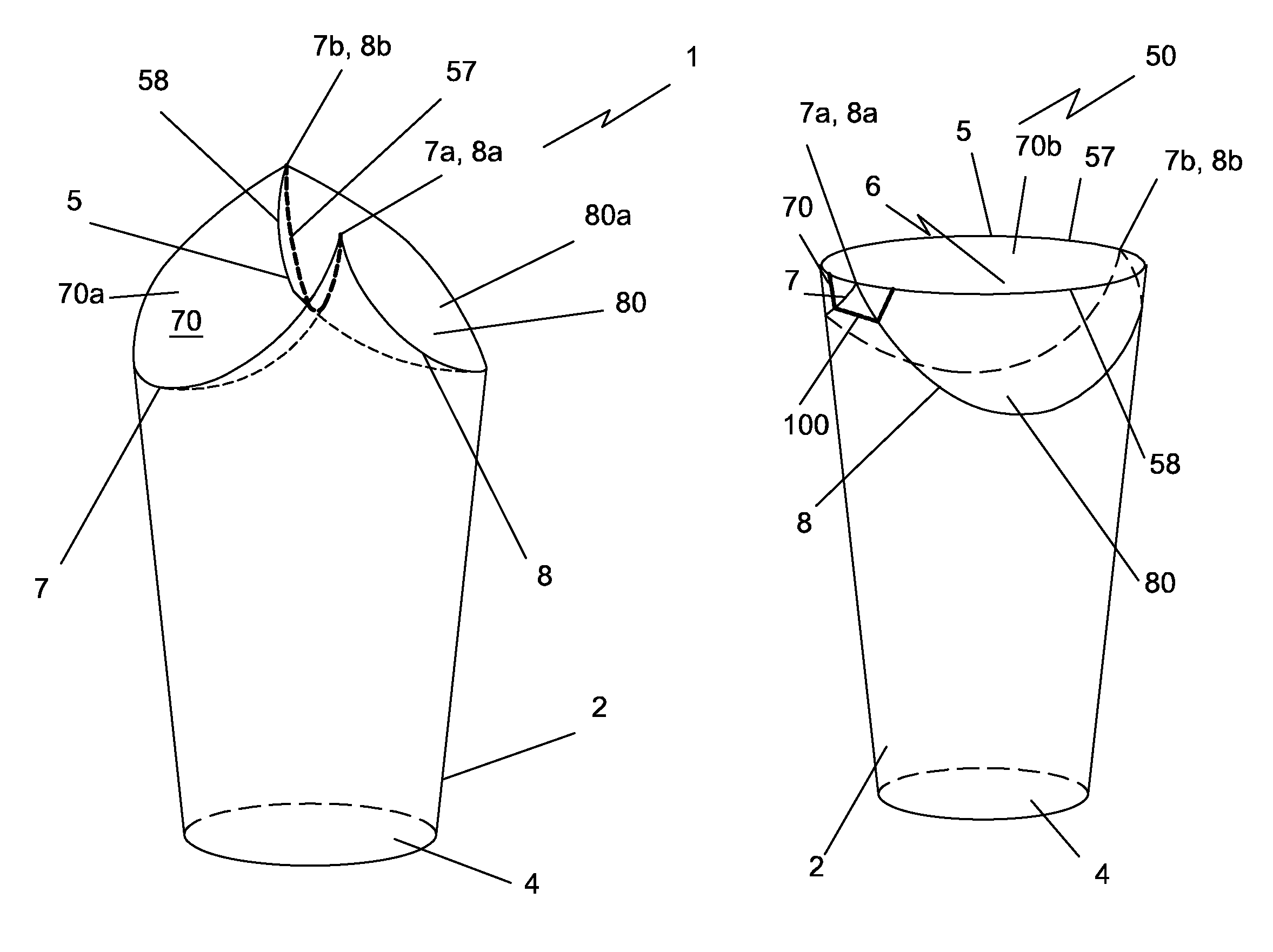

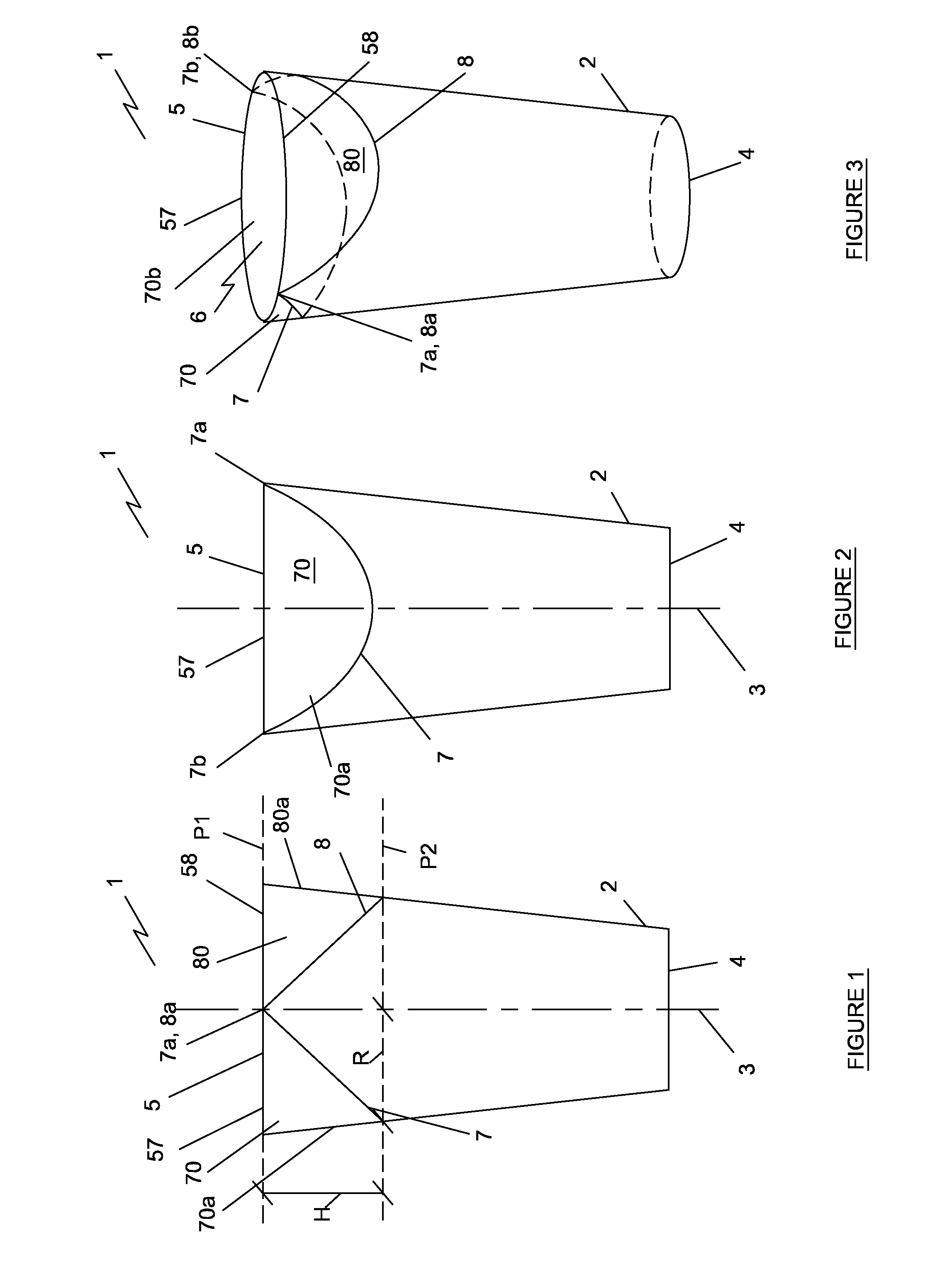

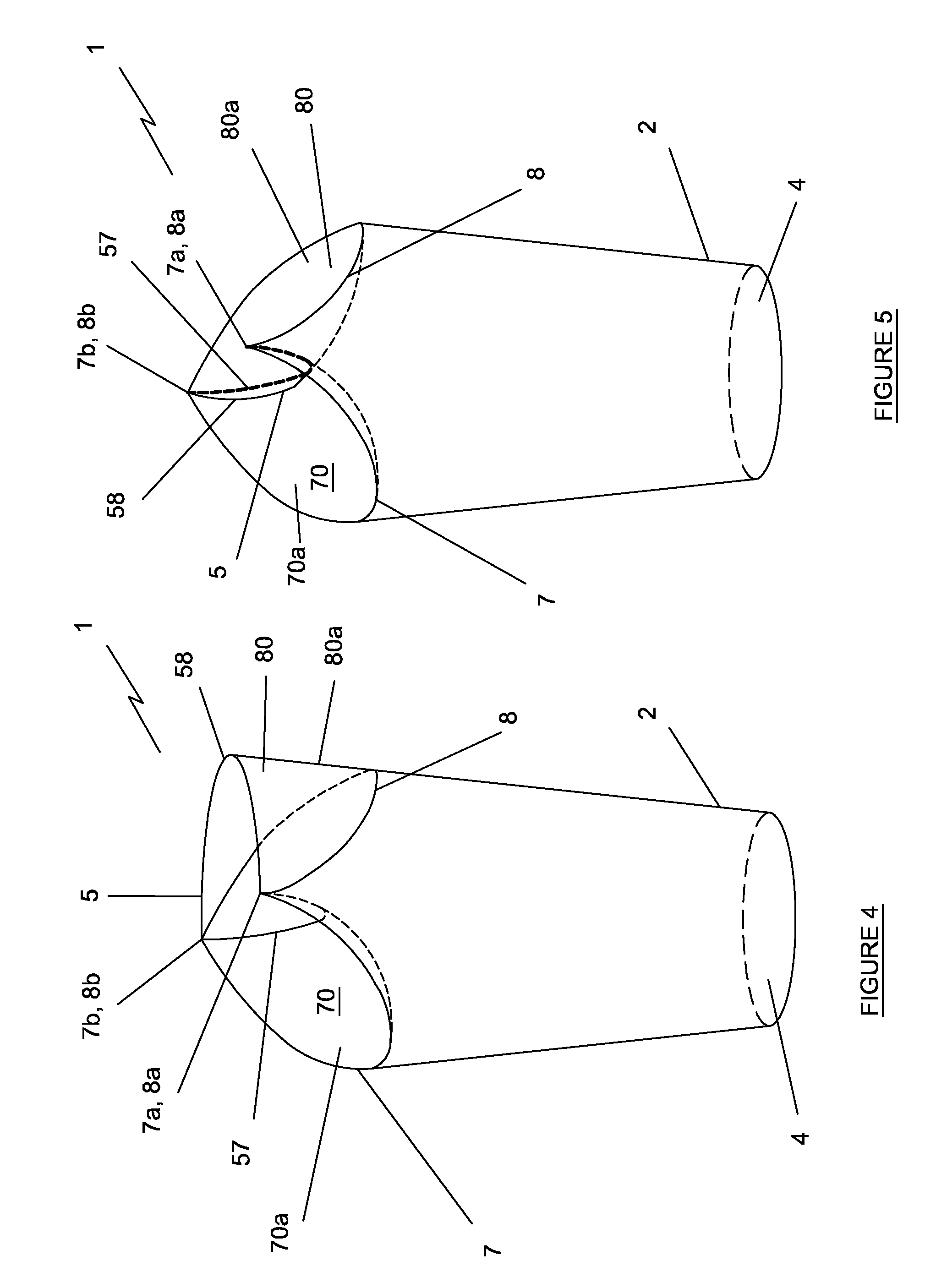

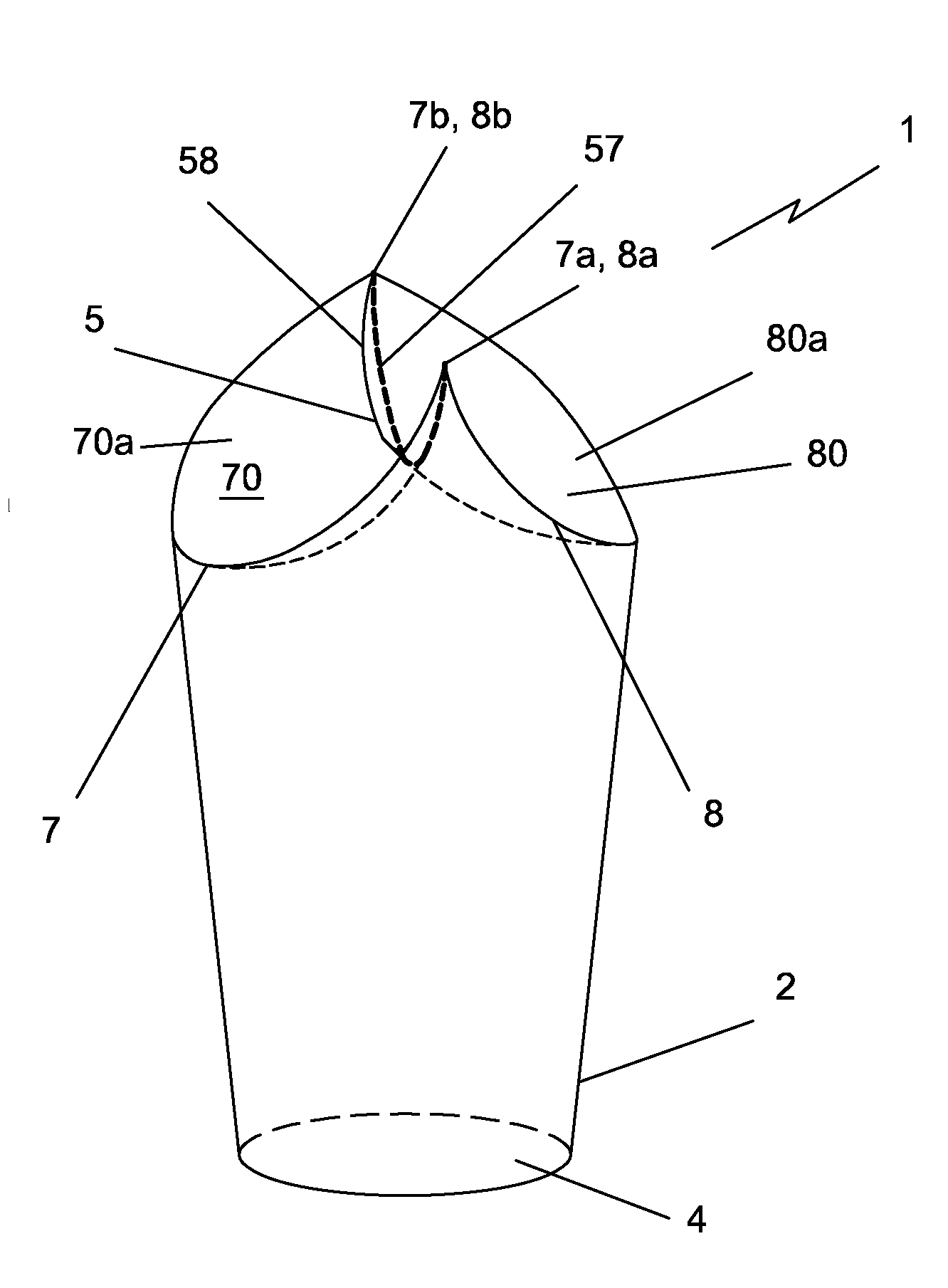

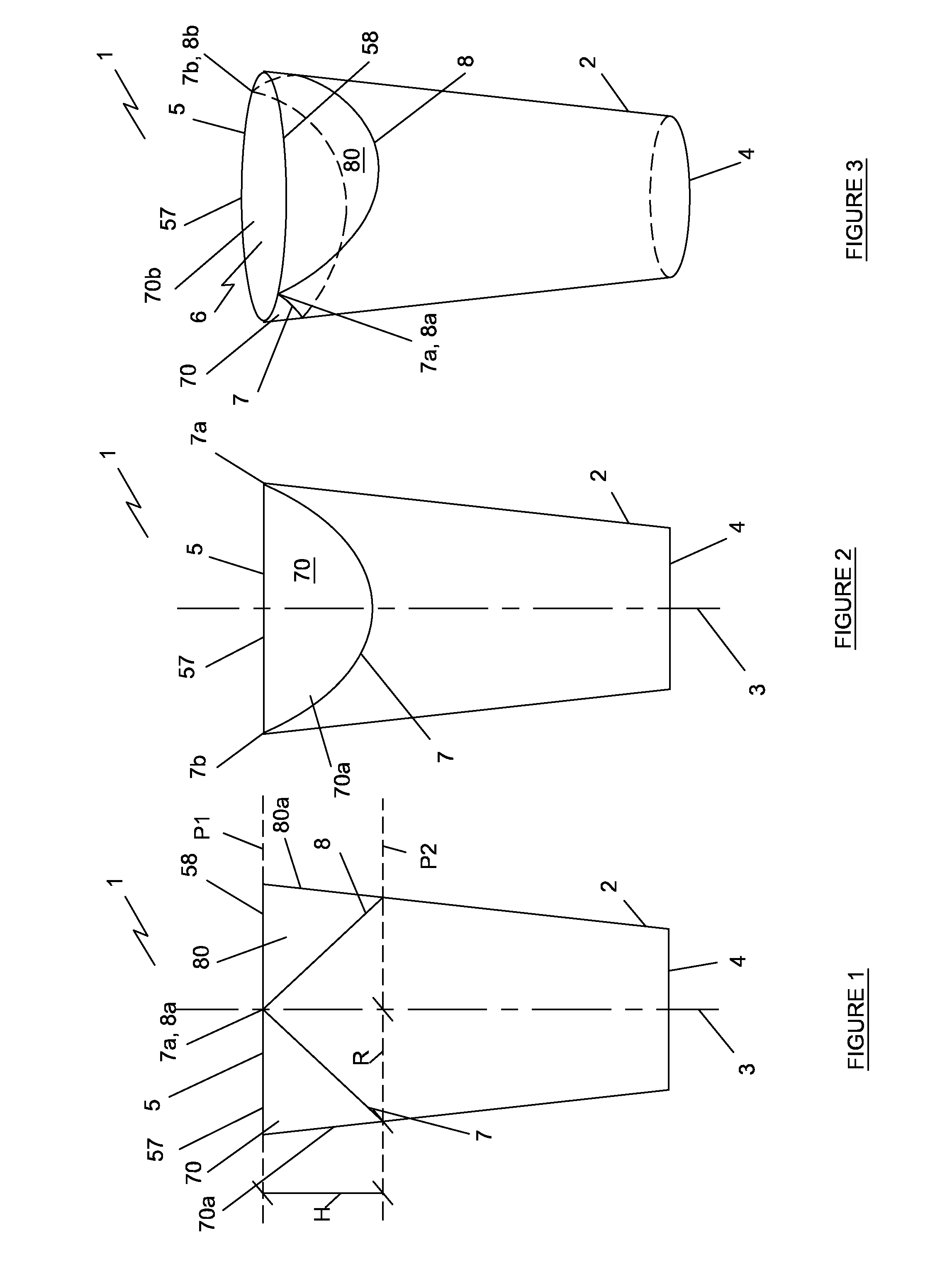

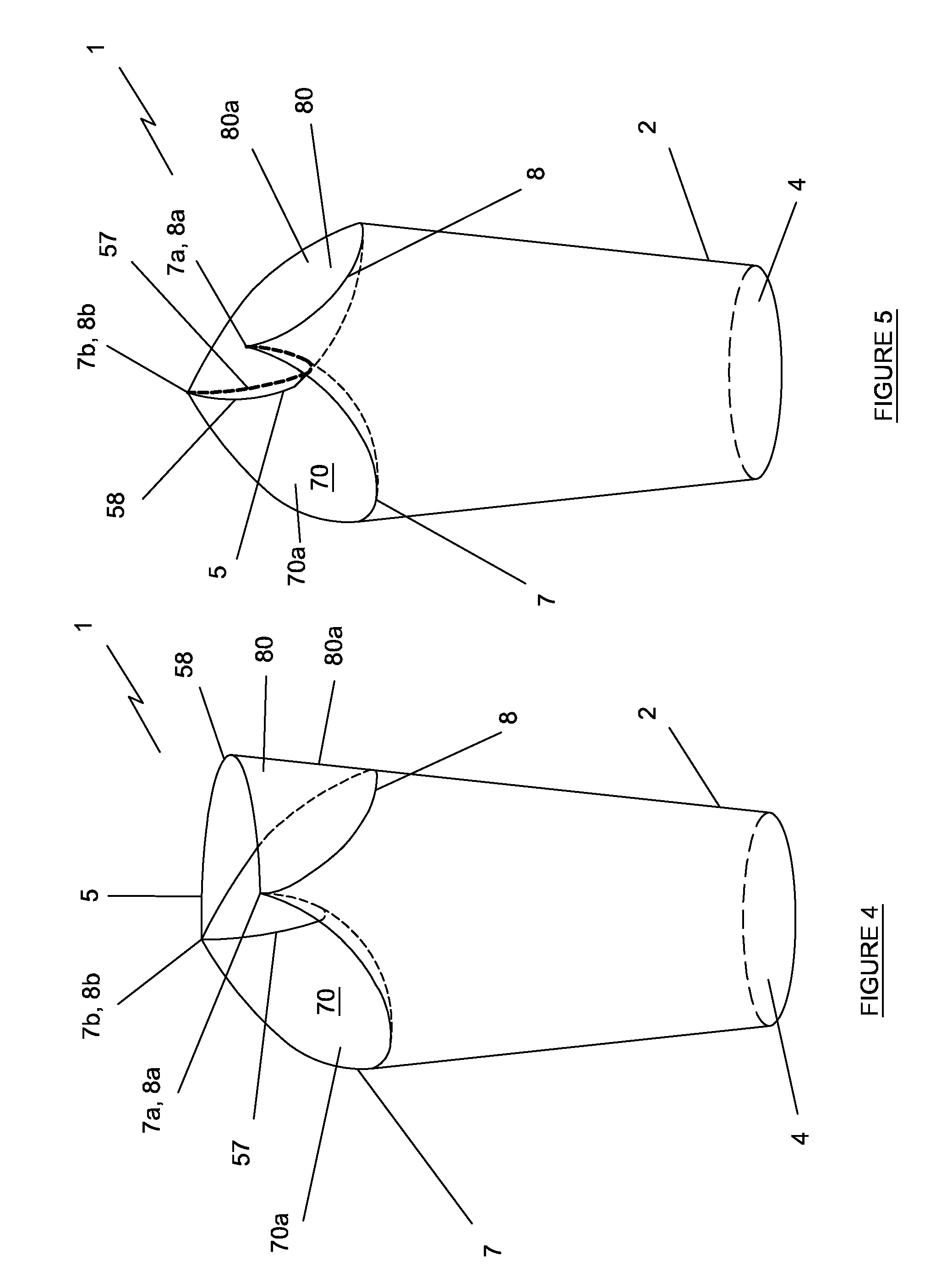

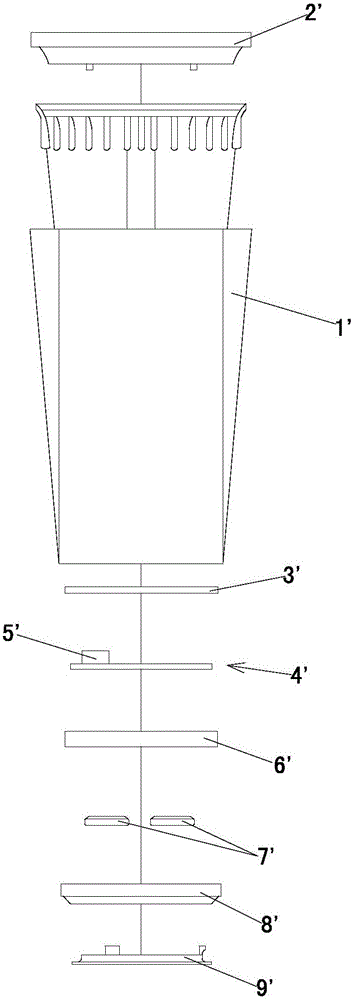

Cup with integral closure flaps

A frusto-conical cup (1, 20, 30, 40, 50) made from a flexible resilient material, having a circular rim (5) defining the top opening (6) of the cup. A pair of arcuate crease lines (7, 8) is formed at the opposing sides of the wall (2) of the cup below the rim defining a pair of flaps (70, 80) for closing the top opening of the cup by folding the flaps along the crease lines. Due to the resilience of the cup material, each flap can toggle between two stable positions on application of an initial external force on the flap, namely an open upright position in which the flap is convex and forms part of the wall of the cup, and a closed slanted position in which the flap changes its shape to concave. In the closed mode, the rim of one flap impinges against the inner face of the second flap and forms a spill-tight seal between the flaps. The seal is maintained due to static opposing forces acting between the flaps.

Owner:HANPAK

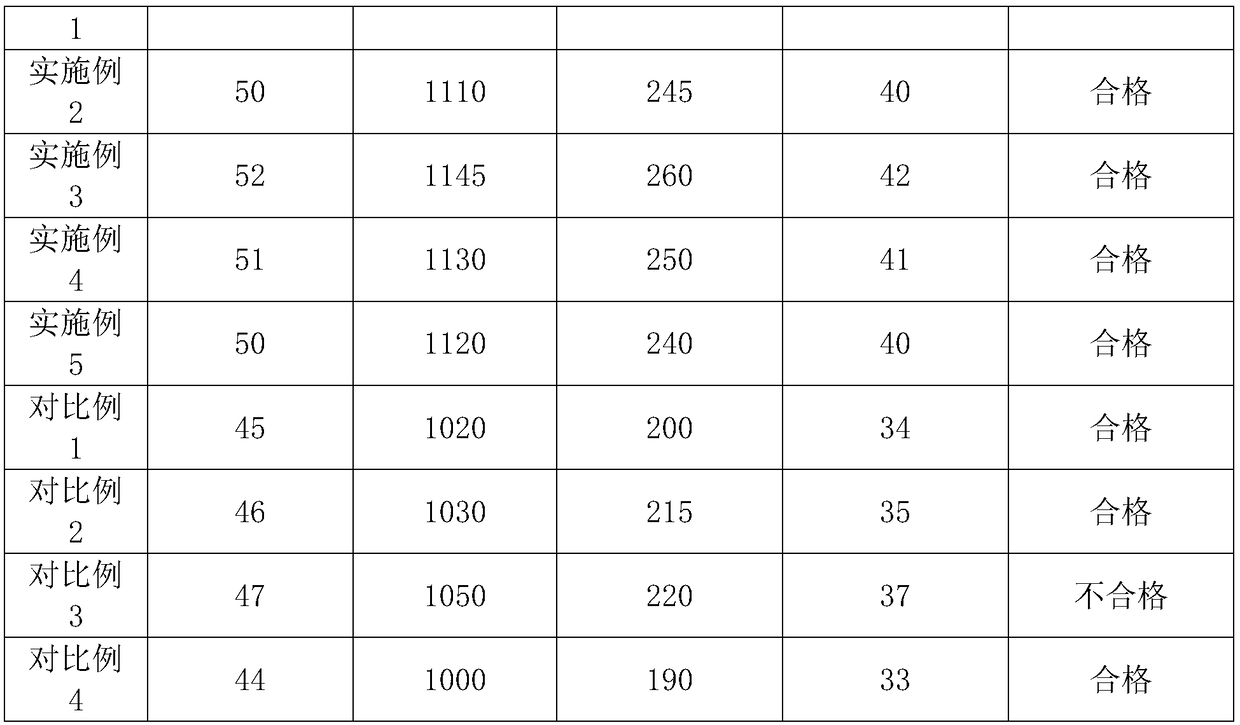

Preparation of high strength piston cup material

The invention relates to a preparation method of a high-strength piston leather cup material and belongs to the field of industrial rubber materials. The technical proposal is as follows: the high-strength piston leather cup material is prepared by the following procedures of batching materials, mixing, calendaring, sulfuration and inspection, wherein, the batched materials comprise nitrile rubber, an accelerating agent, zinc oxide, stearic acid, an aging inhibitor, a softener and carbon black as a reinforcing agent; the materials in batching also comprise sulfur; and the carbon black as the reinforcing agent is carbon black which is prepared by a natural air tank method. The parts by weight of the materials are as follows: 100 parts of nitrile rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 1 to 2 parts of DM accelerating agent, 1 to 3 parts of sulfur, 2 to 3 parts of IPPD aging agent, 5 to 10 parts of DBP softener and 60 to 120 parts of carbon black prepared by the natural air tank method. The material processed by using the method has tear strength of 80.28KN / m by sulfuration and inspection, thus improving the service life of the product.

Owner:信义集团公司

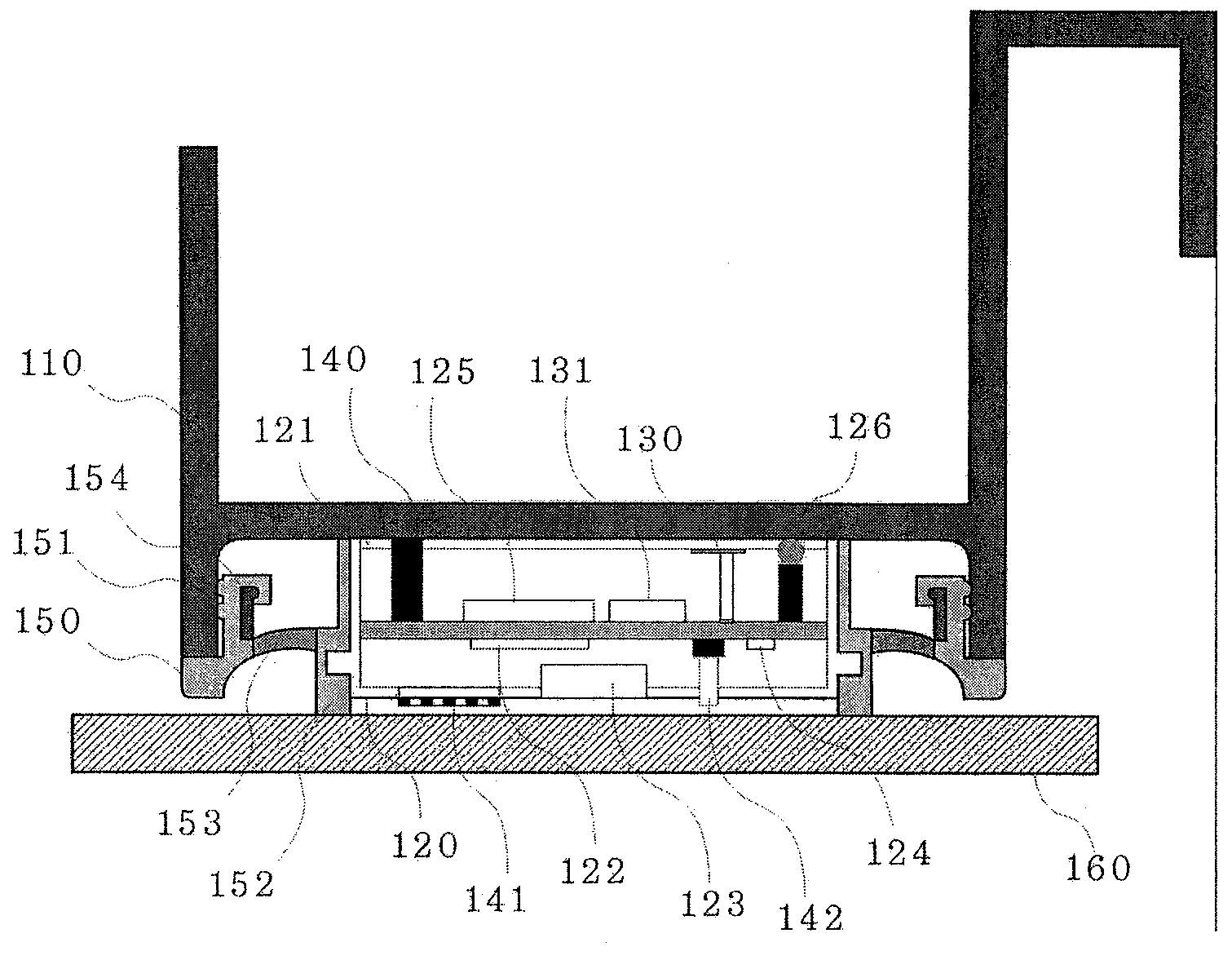

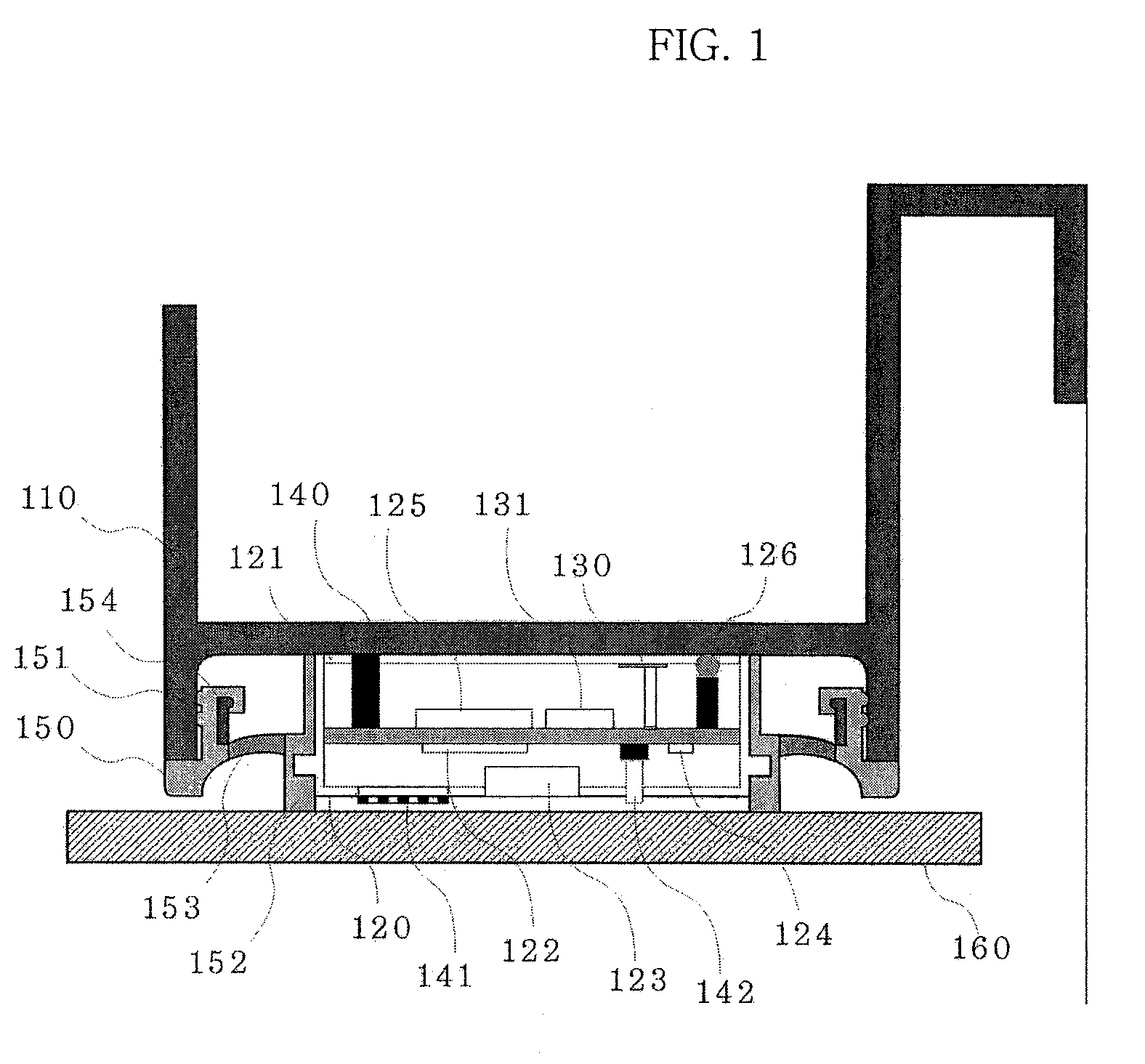

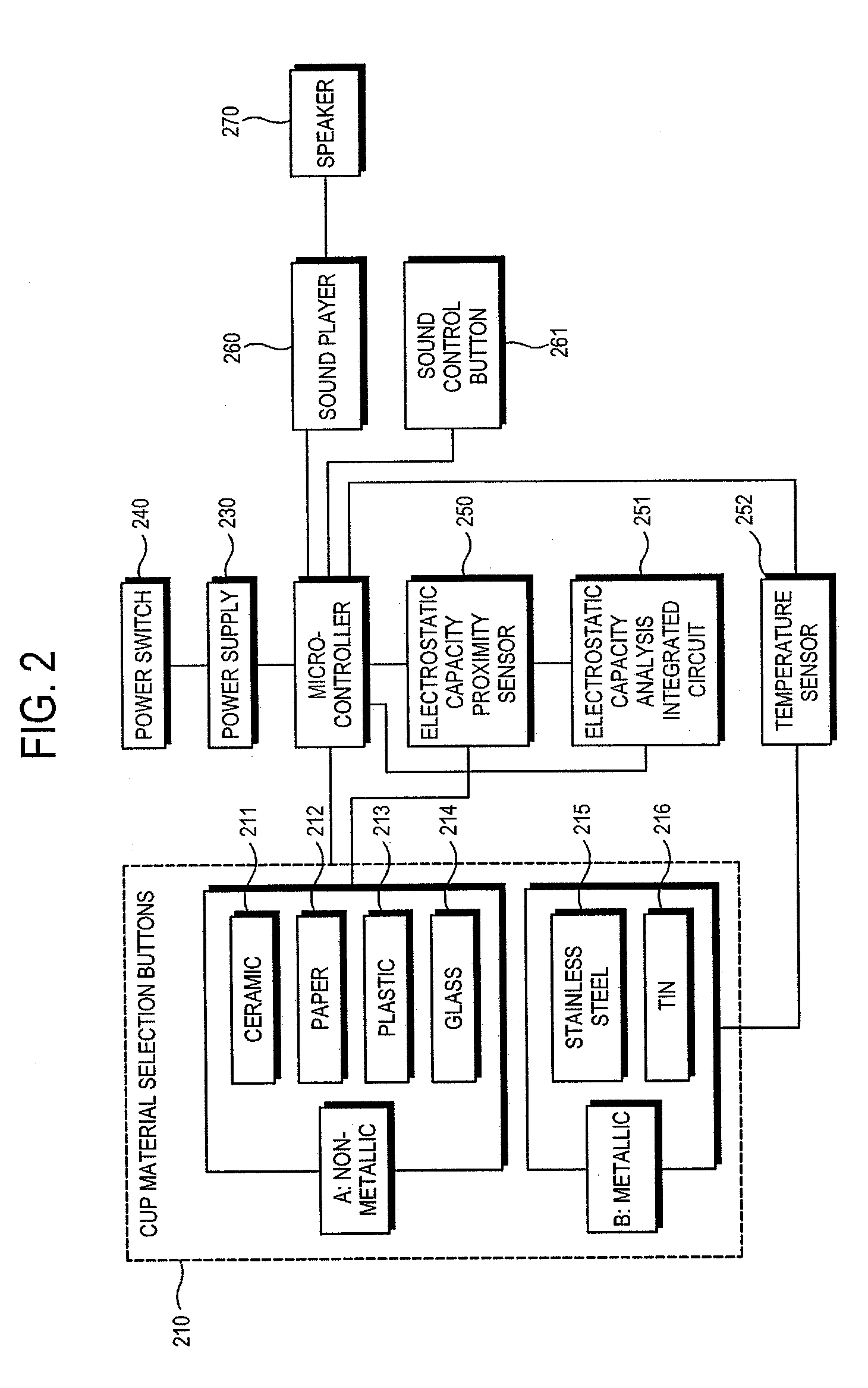

Smart cup having play module and method of manufacturing thereof

InactiveUS20090239440A1Good adhesionEasy detachmentMusical toysDwelling equipmentCapacitanceProximity sensor

Provided is a smart cup having a sound player which is driven by sensors controlled by a micro-controller, to thus control the output of the sound player and extend function and use of a general cup to thereby give help to a daily life of users who use the smart cup. The smart cup includes: a main body of a cup; a play module case; and a silicon coupling portion. The play module detects whether a temperature change occurs in the cup or water-soluble liquid is contained in the cup, to thereby reproduce a built-in sound and includes: a cup material selection button unit; a power switch; a temperature sensor which measures temperature of the cup; an electrostatic capacity proximity sensor which measures a change of an electrostatic capacity; an electrostatic capacity analysis integrated circuit which detects sensitivity of the electrostatic capacity proximity sensor, a detection distance, a changed electrostatic capacity; and a micro-controller which determines whether or not sound will be reproduced.

Owner:KANG HO JOONG

Cup with integral closure flaps

A frusto-conical cup (1, 20, 30, 40, 50) made from a flexible resilient material, having a circular rim (5) defining the top opening (6) of the cup. A pair of arcuate crease lines (7, 8) is formed at the opposing sides of the wall (2) of the cup below the rim defining a pair of flaps (70, 80) for closing the top opening of the cup by folding the flaps along the crease lines. Due to the resilience of the cup material, each flap can toggle between two stable positions on application of an initial external force on the flap, namely an open upright position in which the flap is convex and forms part of the wall of the cup, and a closed slanted position in which the flap changes its shape to concave. In the closed mode, the rim of one flap impinges against the inner face of the second flap and forms a spill-tight seal between the flaps. The seal is maintained due to static opposing forces acting between the flaps.

Owner:HANPAK

Water resistant leather cup material

The invention discloses a water resistant leather cup material, which is composed of the following raw materials in parts by weight: 90 to 95 parts of butyronitrile rubber, 2 to 4 parts of epoxy linseed oil, 30 to 40 parts of filling material, 8 to 12 parts of zinc stearate, 1 to 2 parts of aluminum nitride, 1 to 2 parts of white factice, 0.3 to 0.6 part of antioxidant 168, 0.1 to 0.5 part of anti-aging agent RD, 2 to 3 parts of dimethyl decanedioate, 1 to 2 parts of bamboo charcoal powder, and 1 to 3 parts of fast extruding carbon black N550. The material has a high environmental fire resistant and water resistant performance and a long service life, can be used under severe and damp circumstance, and maintains excellent and stable properties at the same time.

Owner:WUHU JIACHENG ELECTRONICS TECH

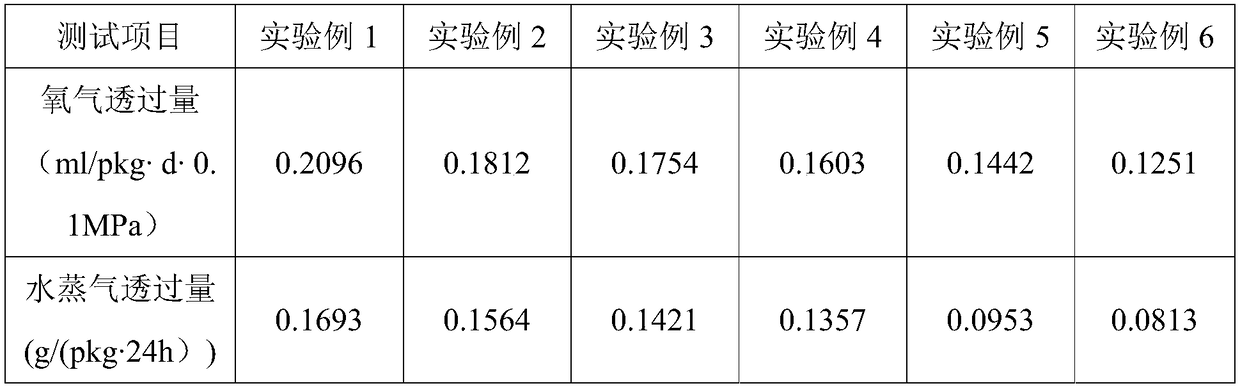

Preparation methods of biodegradable yoghourt-cup material and product

InactiveCN108192303AOvercome barrierOvercome the disadvantage of high brittlenessCross-linkPolymer science

The invention provides preparation methods of a biodegradable yoghourt-cup material and a product, and belongs to the field of polymer materials. The biodegradable yoghourt-cup material is prepared from the following components: 55-75 parts of polylactic acid, 15-35 parts of thermoplastic hydrophobic starch, 5-10 parts of poly(butyleneadipate-co-terephthalate), 0.3-0.7 part of a nucleating agent,0.5-1 part of a chain extender, 0.1-0.3 part of a cross-linking agent and 0.1-0.15 part of a compatilizer. The material provided by the invention has the advantages that the polylactic acid are blended with the thermoplastic hydrophobic starch and the poly(butyleneadipate-co-terephthalate) for modification, and then the auxiliary agents such as the nucleating agent, the chain extender, the cross-linking agent, the compatilizer and the like are added, so that the defects of low barrier property and high brittleness of the polylactic acid are overcome, good mechanical strength and good flexibility are achieved, the product cost is reduced, the application field of a polylactic acid material is expanded, and the pollution to the environment is greatly reduced compared with the pollution of the petroleum-based plastic.

Owner:JILIN COFCO BIOCHEM +1

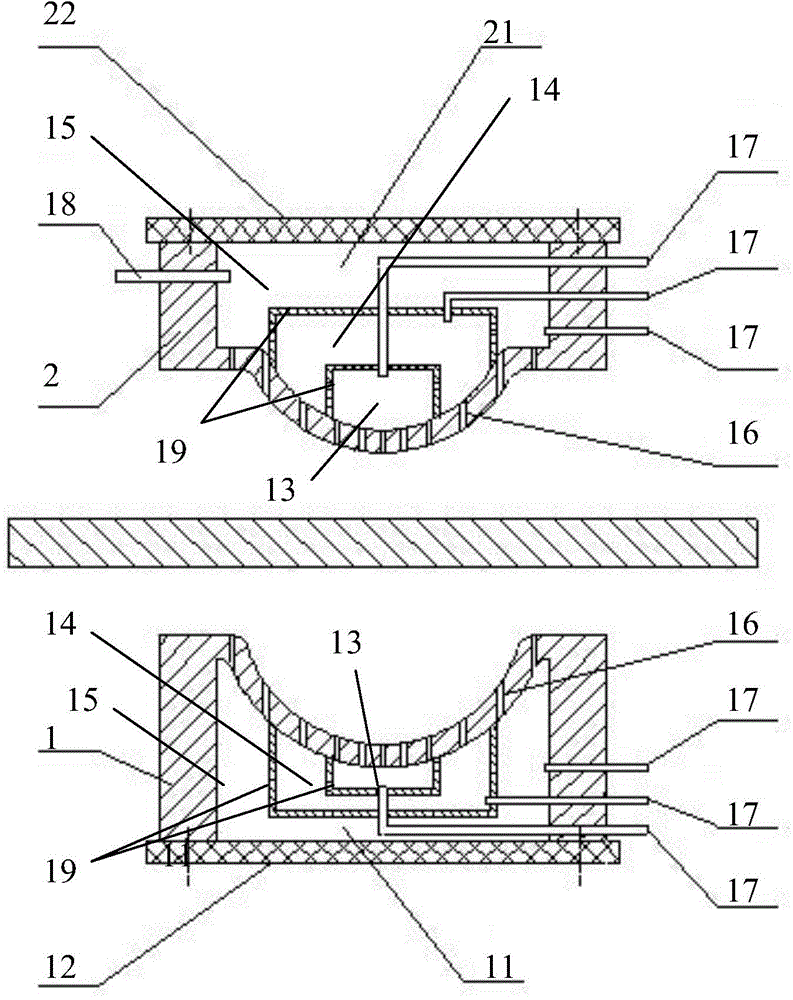

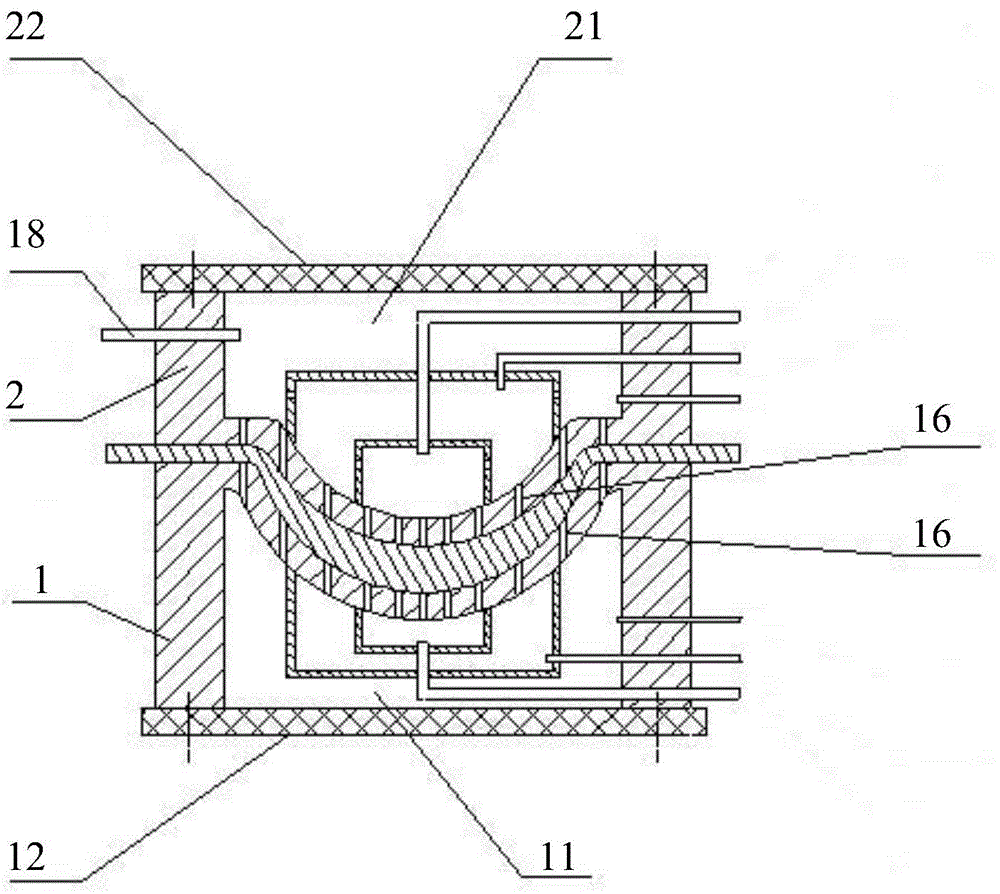

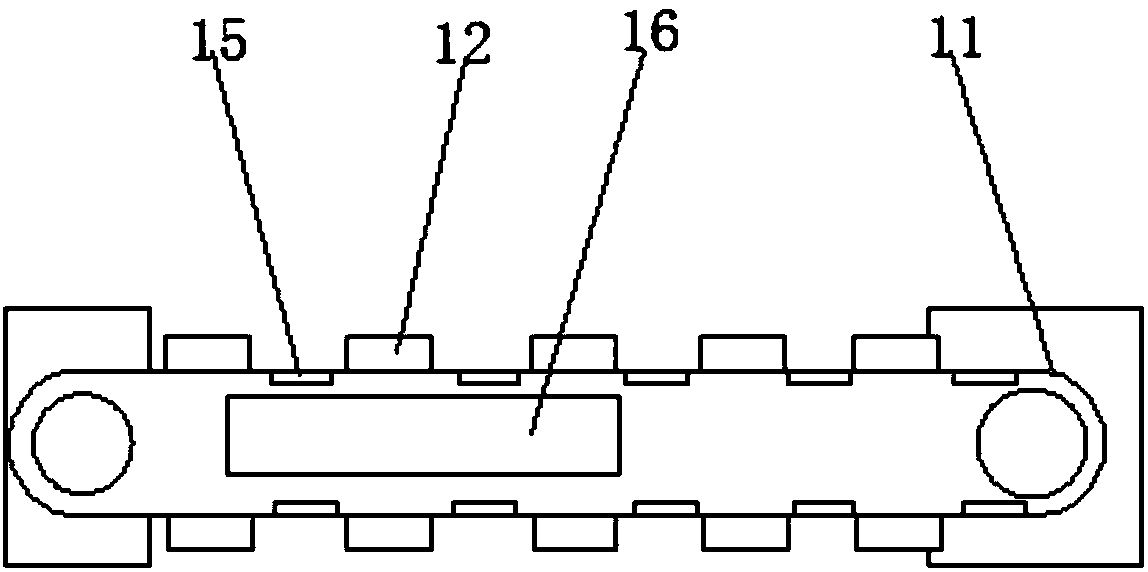

Underwear cup molding die and underwear molding method thereof

The invention discloses an underwear cup molding die. Cavities are formed in upper and lower dies, and superheated airflow is introduced into the cavities for heating, so that the die is rapidly preheated in a short time. The cavities are separated into multiple areas for respectively performing heating treatment at different temperatures, the condition that the temperature on the surface of the die is consistent with the temperature needed at each part of a mold pressing material is ensured, the heating effect of the cup material is improved, the problem caused by extremely high or low temperature is solved, the quality of the mold cup is improved, and the mold cup molding process is effectively perfected and improved. The molding die is suitable for molding modern three-dimensional cups of which the lower sides are thick and the upper sides are thin, so that the mold pressing temperature distribution on the die surface is reasonable, only the hot airflow is introduced into the first area of the lower die during mold pressing, so that the heating can be performed, the power consumption is reduced, the time is saved, the working efficiency is improved, the mold cup quality is improved, and the mold cup molding process is effectively perfected and improved.

Owner:SUZHOU UNIV

Carbon titanium combining self-protection brick for blast furnace hearth and furnace bottom

The invention discloses a carbon titanium combining self-protection brick for a blast furnace hearth and a furnace bottom. By special ingredient proportioning, the carbon titanium combining self-protection brick has micropores and high thermal conductivity of microporous carbon bricks, molten iron corrosion resistance anti-scouring performance of a ceramic cup material and the effects of a titanium ore protecting furnace, can solve the problems that the blast furnace hearth is burnt through frequently in recent years and the furnace bottom is too high in warming speed and short in service life, and is expected to become a substitute product for a carbon brick for a blast furnace.

Owner:ZHENGZHOU ANNEC IND

Film-coating process for paper cup material

InactiveCN107471809AAppropriate cohesionEfficient recyclingLamination ancillary operationsLaminationFiberPulp and paper industry

The invention provides a film-coating process for a paper cup material. The film-coating process comprises the following steps: (1) unreeling base paper, and controlling the tension of unreeling to be 30 to 50 kg / m2; (2) subjecting the printing surface of conveyed base paper to corona treatment under the current of 4 to 6 A; (3) preparing a polyethylene film with a thickness of 600 to 650 [mu]m, and compounding the printing surface of the conveyed base paper with the polyethylene film through a compound roller running at a high speed under the pressure of 100 to 130 kg / m2 so as to obtain film-coated paper; (4) cooling the film-coated paper by using circulating water with a temperature of 10 to 15 DEG C; (5) carrying out reeling, and controlling the tension of reeling to be 15 to 40 kg / m2; and (6) subjecting paper rolls to storage and transportation. The finished paper cup made of the film-coated paper provided by the invention has good anti-leakage performance; meanwhile, after recovery of the waste paper cup, the plant fiber in the paper cup can be recycled with high efficiency, so valuable plant fiber resources are saved.

Owner:ANHUI YIBAILI ENVIRONMENTAL TECH CO LTD

Method for manufacturing paper cup material

ActiveCN103085443ADoes not affect print qualityDoes not affect the sensory effectLamination ancillary operationsSynthetic resin layered productsCardboardPolyethylene terephthalate

The invention discloses a method for manufacturing a paper cup material. The method comprises the following steps of: 1, taking food-level white cardboard for food package as a base material; 2, sticking a polyethylene terephthalate (PET) aluminum coating film on the front surface of the food-level white cardboard by high-temperature-resistant environmentally-friendly glue; 3, printing patterns on the PET aluminum coating film by high-temperature-resistant composite ink at a temperature being more than 150 DEG C; 4, sticking a PET coverage film on the PET aluminum coating film printed by the ink by adopting transparent composite glue; 5, coating a first layer of polyethylene (PE) spraying film on the back surface of the food-level white cardboard; 6, sticking aluminum foil material paper on the first layer of PE spraying film; and 7, sticking a second layer of PE spraying film on the aluminum foil material paper. A paper cup made of the material has a good printing effect and high quality; and the sense of metal is strong.

Owner:罗明亮 +1

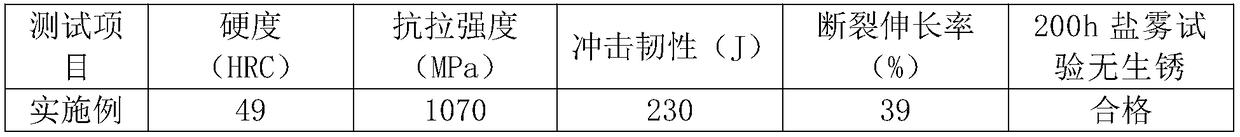

Wear-resistant corrosion-resistant stainless steel cup material and preparation method thereof

The invention discloses a wear-resistant corrosion-resistant stainless steel cup material. The material comprises the following chemical components of, by mass, 0.35-0.55% of C, 0.75-1.15% of Si, 0.80-1.20% of Mn, 5.50-8.50% of Cr, 0.55-0.85% of Cu, 0.18-0.38% of Mo, 0.20-0.40% of V, 0.20-0.06% of Co, 0.03-0.05% of Nb, 0.02-0.04% of Ti, 0.01-0.03% of Ce, 0.0010-0.0040% of Yb, 0.0010-0.0035% of B,the balance Fe and inevitable impurities. The stainless steel cup material has relatively high wear resistance and high corrosion resistance, low in cost, good in antibacterial performance, strength,hardness and heat resistance and excellent in comprehensive performance.

Owner:合肥久新不锈钢厨具有限公司

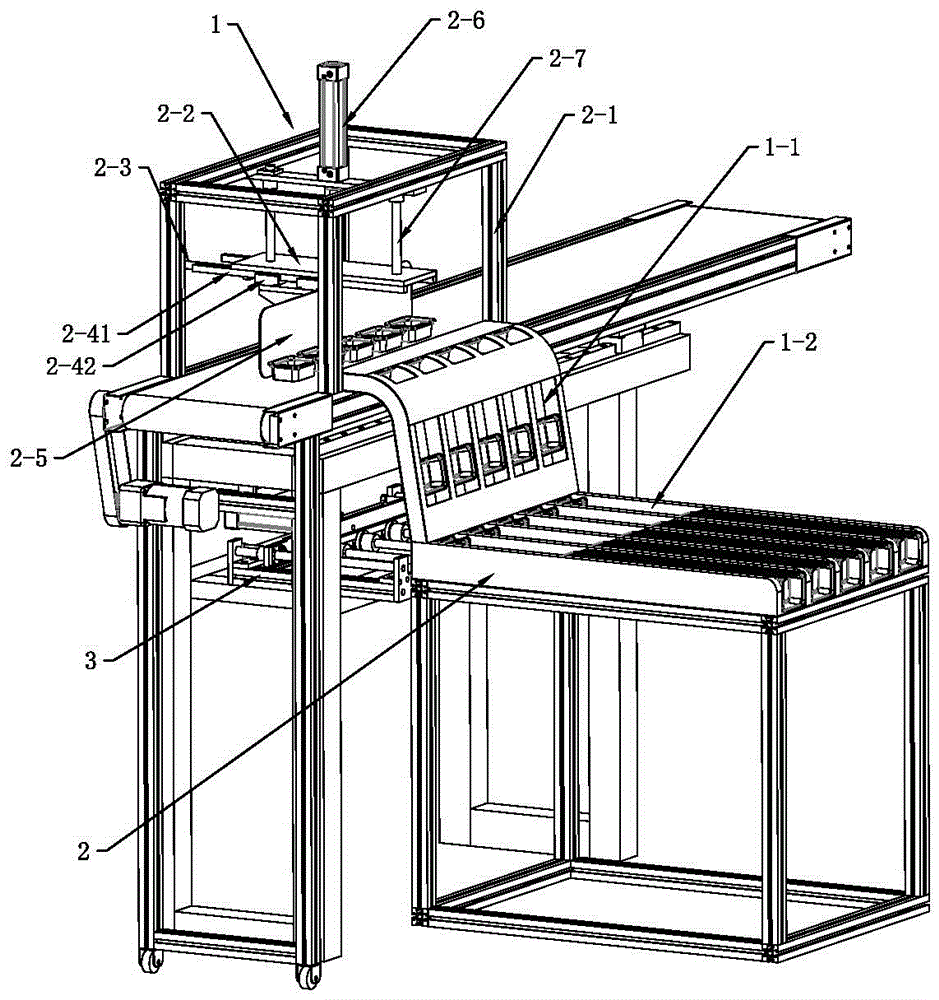

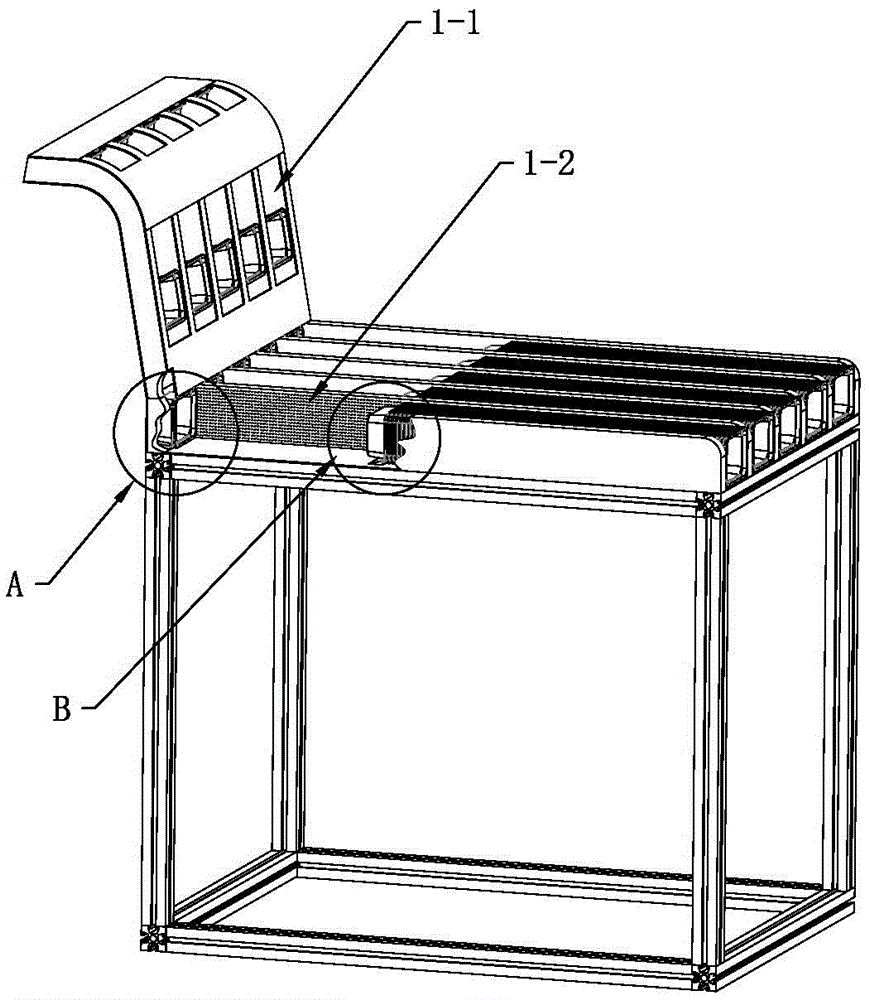

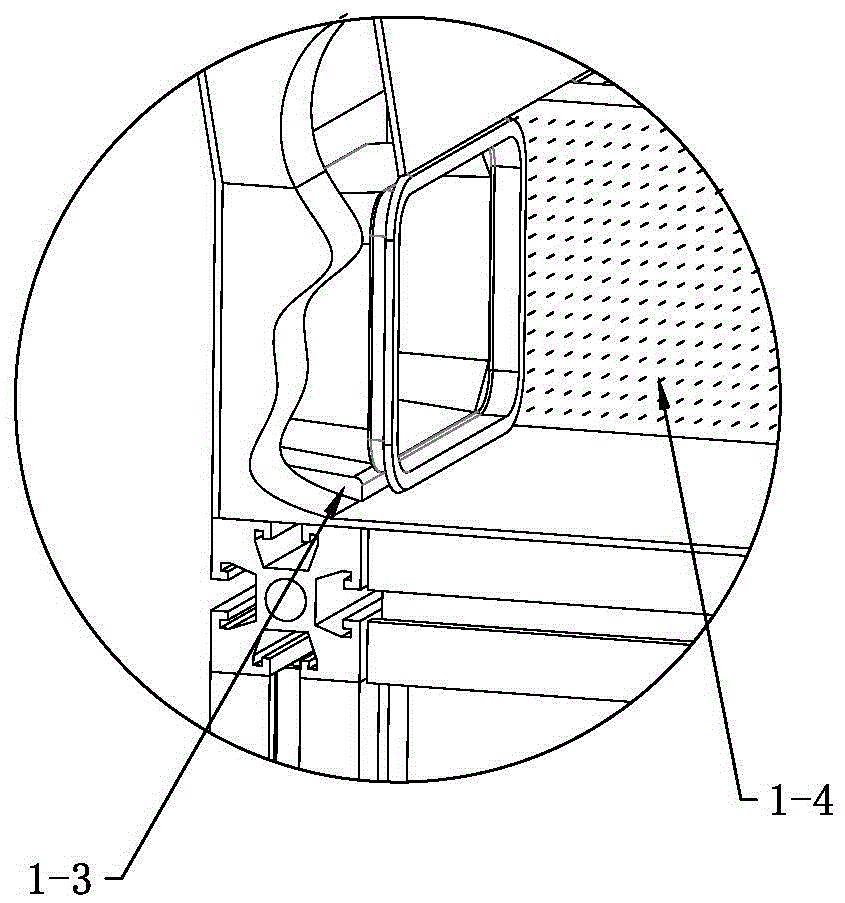

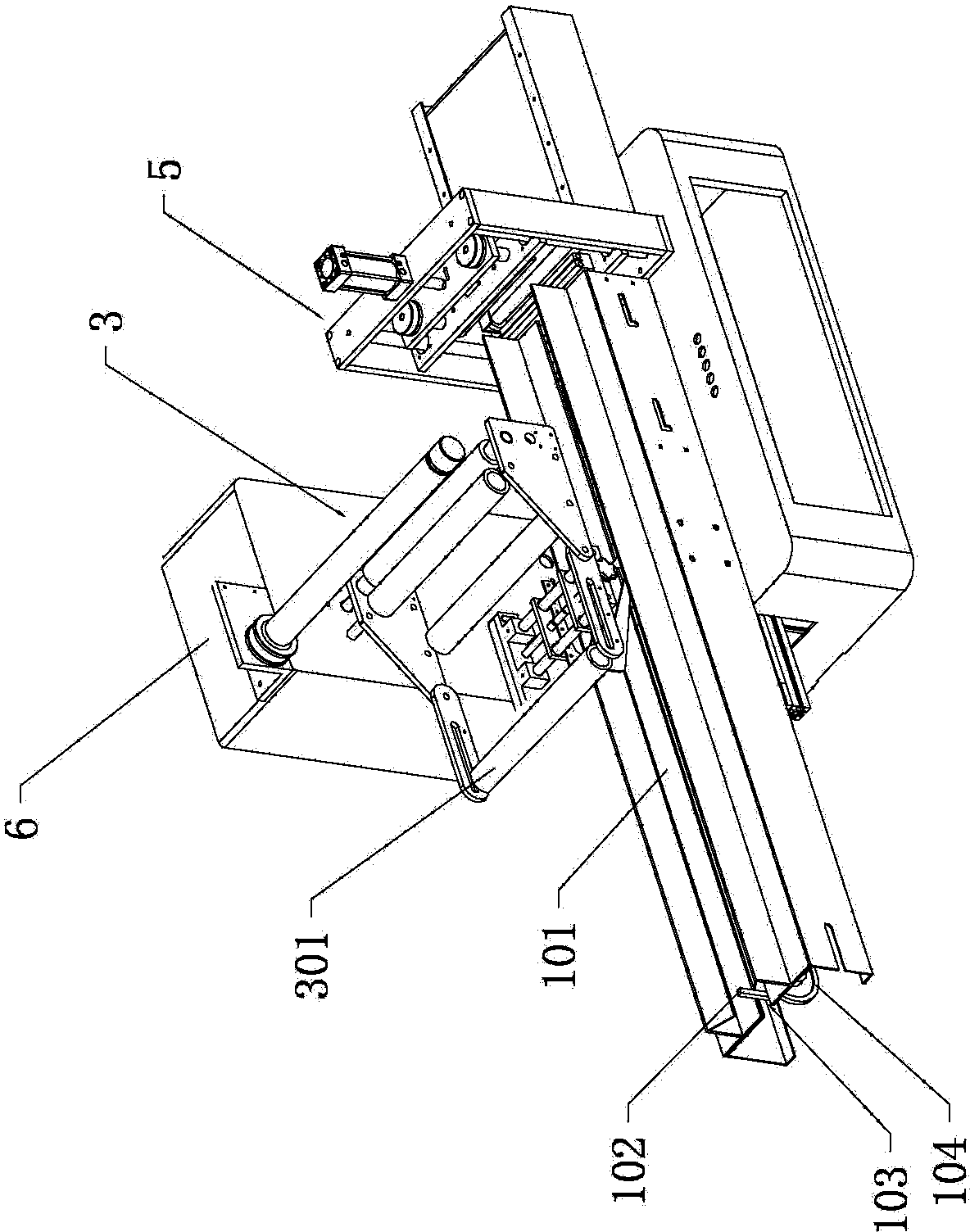

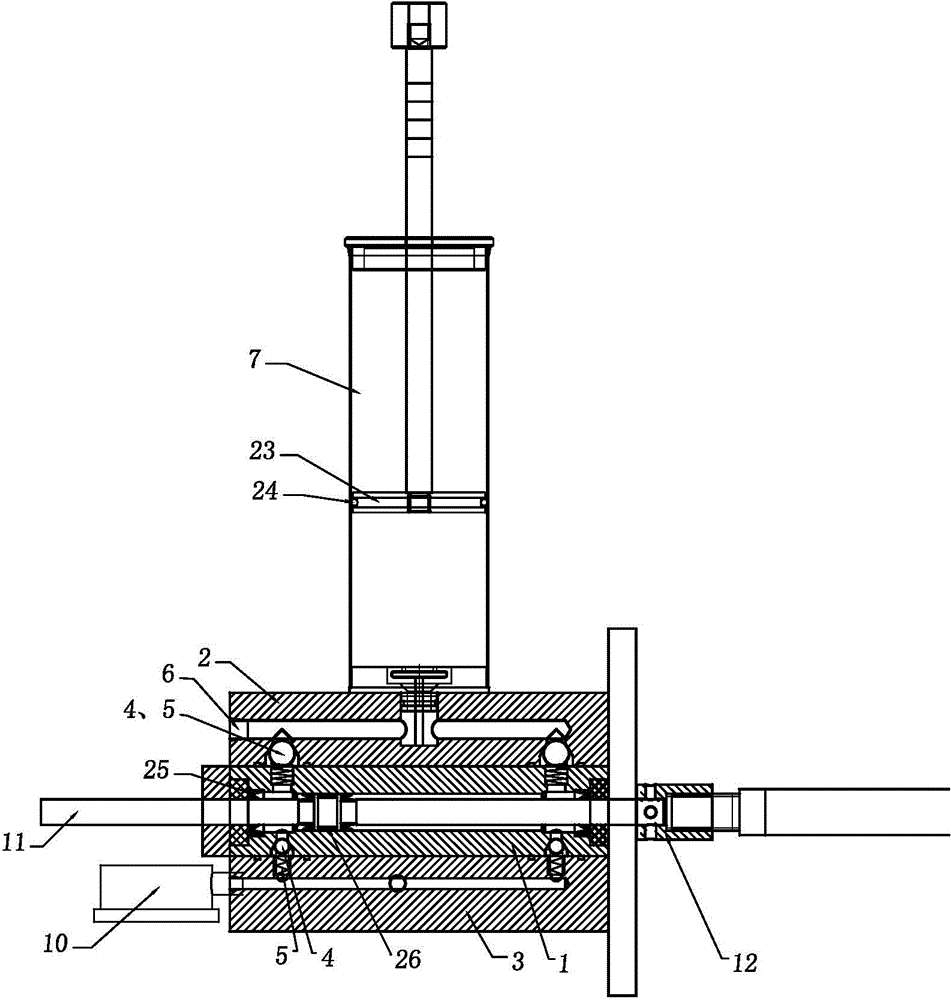

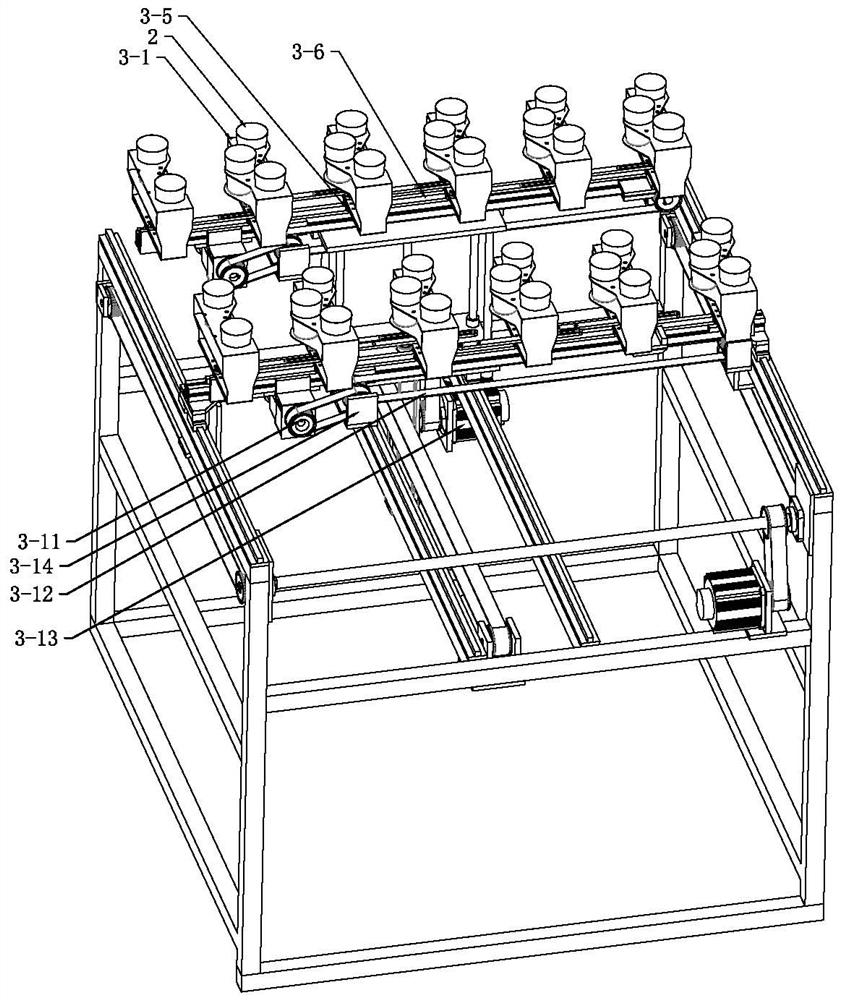

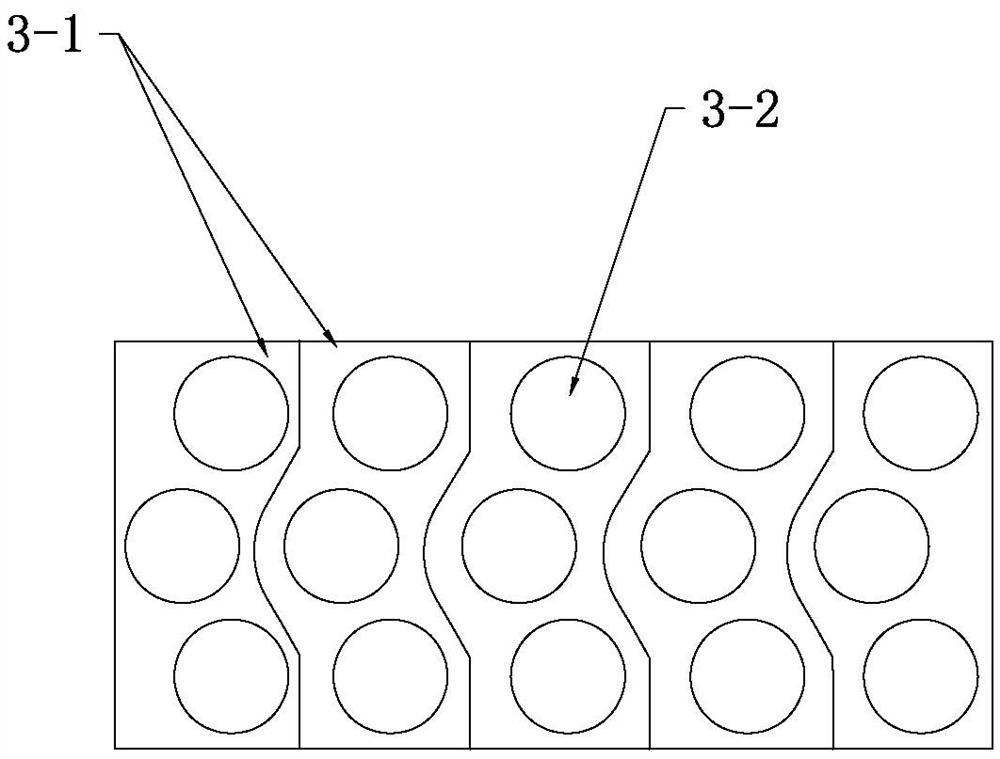

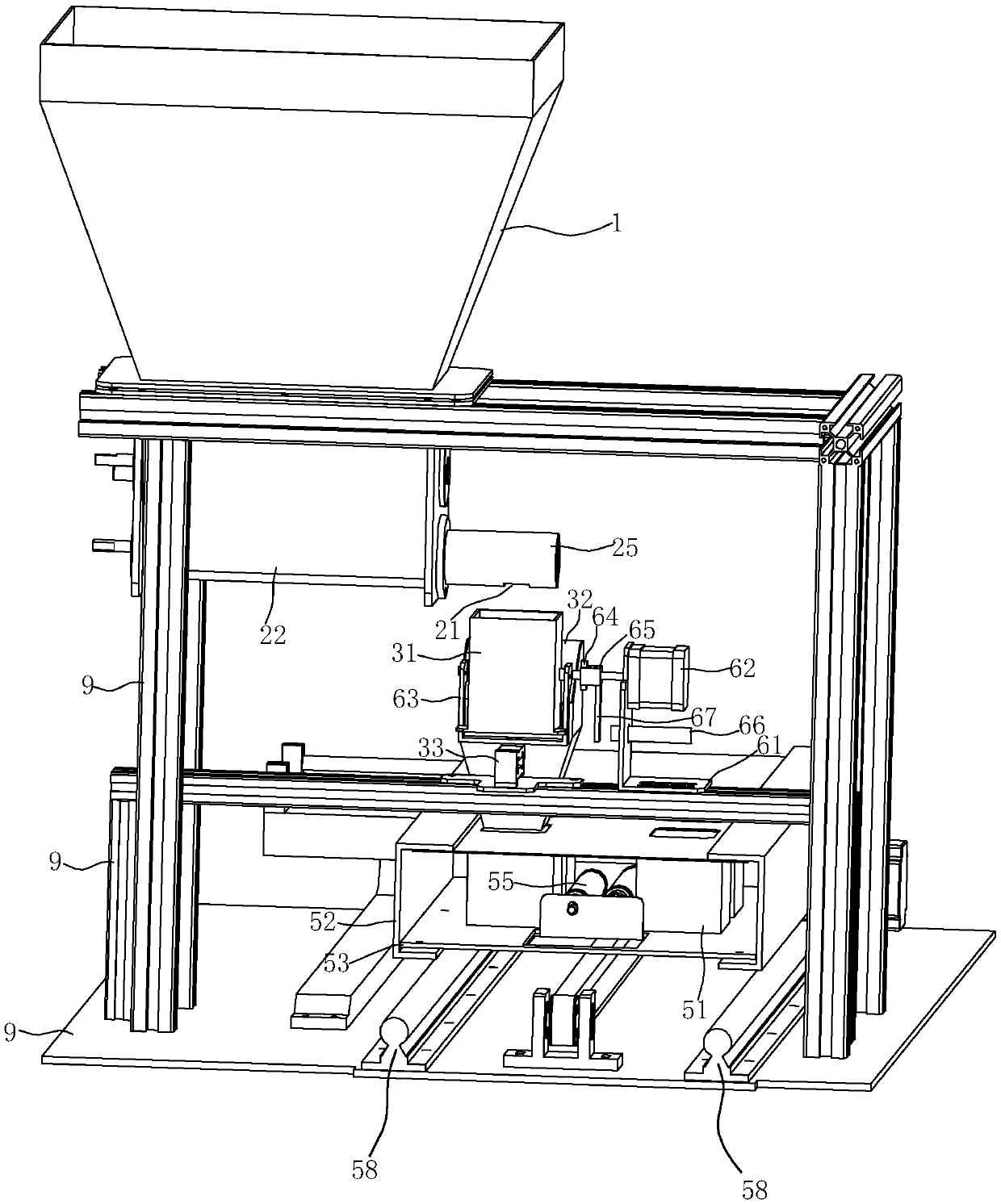

Material pushing and stacking device

InactiveCN106429466APlay the role of slowing down and stoppingEasy and smooth nestingStacking articlesStack effectAutomation

The invention discloses a material pushing and stacking device. The material pushing and stacking device comprises a stacking device, a pushing mechanism and a push rod device. A stacking channel of the stacking device comprises a slide channel and a stacking and pushing channel. The pushing mechanism pushes cup materials into a feeding inlet of the slide channel. The cup materials can creep down along the slide channel under the gravity action of the cup materials and then fall into the stacking and pushing channel from a material falling opening of the slide channel. A push rod of the push rod device pushes the cup materials to advance, and the cup materials are stopped and clamped onto a rim lug. On one hand, the rim lug plays the effect of decelerating and stopping the cup materials; and on the other hand, the bottom of each cup material can be cushioned up so that the next cup material can be stacked smoothly. Compared with the prior art, the material pushing and stacking device has the following main beneficial effects that the degree of automation is high, and human resource cost is reduced; the stacking effect is good, the cup materials are stacked, and meanwhile the entire stacked cup materials can be pushed; and the cup materials can be pushed and stacked at the same time, and thus efficiency is greatly improved.

Owner:GUANGDONG LONGXING PACKAGING IND

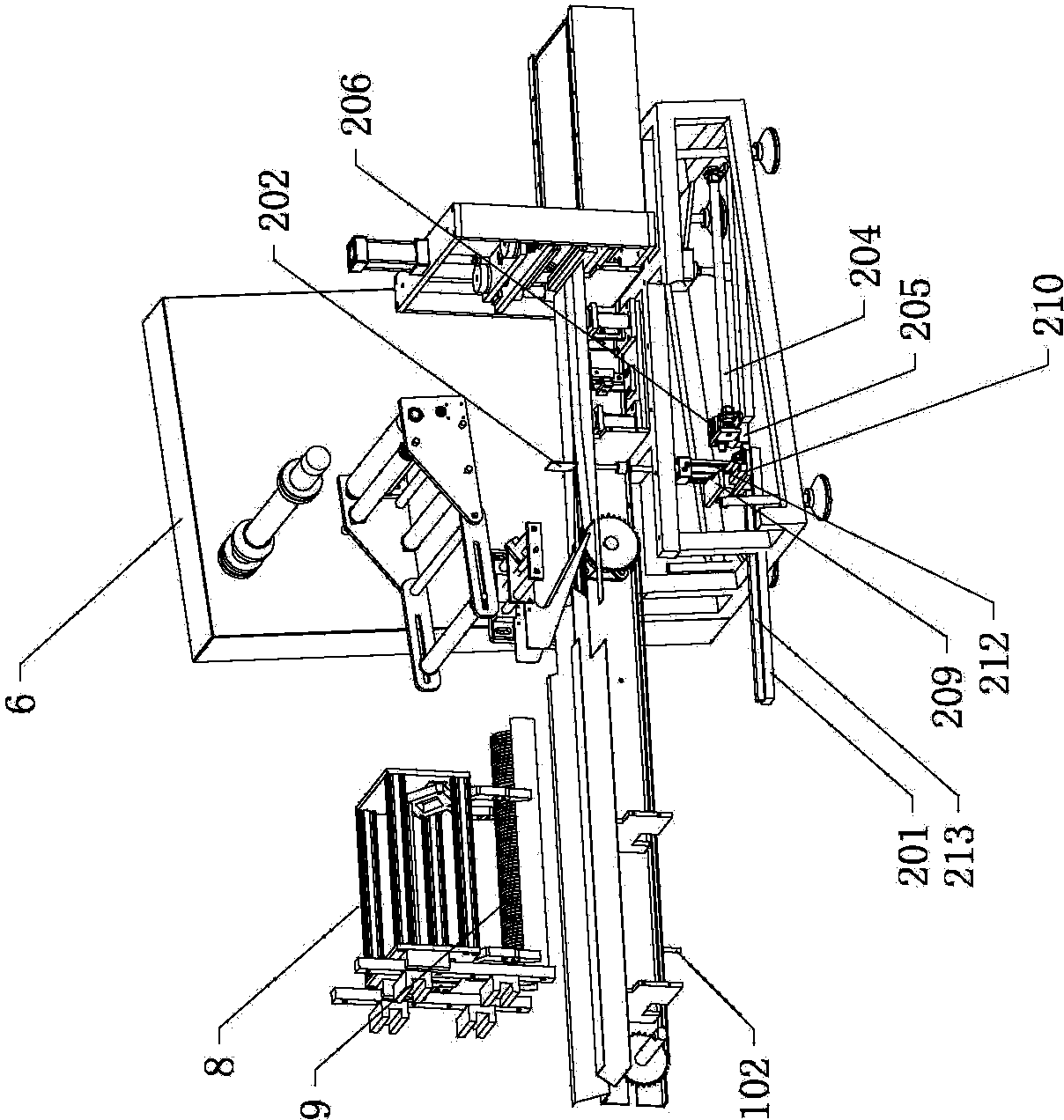

Multifunctional automatic bagging device for cup, bowl and cover

The invention discloses a multifunctional automatic bagging device for a cup, a bowl and a cover. The multifunctional automatic bagging device comprises a leaning unit, a conveying unit, a film supporting and material conveying unit, a bagmaking heat sealing unit and a controller. Compared with the prior art, the multifunctional automatic bagging device has the advantages that by arrangement of the leaning unit for enabling a cup material such as the cover to be leaned against and preventing the cup material from being toppled over, the multifunctional automatic bagging device is wider in application range, can be used for automatically conveying and bagging a common water glass and can be also used for conveying, bagging and encapsulating of cup pieces (including a cup, a bowl, a box, a cover and the like) with diameters close to or greater than the heights and a plurality of rows of complete cup pieces of plastic small jelly containers (such as a peach-heart-shaped cup, a triangular cup, an elliptical cup and covers with other shapes) which have specific shapes and cannot roll away. According to the multifunctional automatic bagging device, automatic product conveying and bagging are realized, the automation degree is high, and the working efficiency is high; the demand for the quantity of workers is reduced, and labor cost is lowered; contact between a human body and a cup piece is avoided, so that the product is more sanitary and reliable.

Owner:GUANGDONG LONGXING PACKAGING IND

Digital intelligent color paste pump

ActiveCN104564630AImprove output performanceHigh precisionPump controlPositive-displacement liquid enginesAutomatic controlPulp and paper industry

The embodiment of the invention discloses a digital intelligent color paste pump which comprises a pump body, a color paste pump input one-way valve bank and a color paste pump output one-way valve bank, wherein the color paste pump input one-way valve bank and the color paste pump output one-way valve bank are respectively arranged on the two sides of the pump body; a piston injection type color paste cup is arranged on one side of the color paste pump input one-way valve bank in a connecting way; the color paste cup is communicated with the color paste pump input one-way valve bank, and a piston rod in the color paste cup is connected with material pressing air cylinders arranged on the two sides of the color paste cup through a color paste cup material pressing plate arranged on the piston rod; a double-output shaft piston shaft is arranged in the pump body, the lower part of the double-output shaft piston shaft is connected with a pump body actuating air cylinder, and the pump body actuating air cylinder is a double-output shaft air cylinder and is used for driving the double-output shaft piston shaft to do leftward and rightward movement. The digital intelligent color paste pump further comprises a control computer, the control computer is connected with the pump body through a copper pipe and is used for controlling the on / off of the color paste pump, so that the proportion of color paste output is controlled. The invention aims to provide the digital intelligent color paste pump capable of automatically controlling and accurately outputting the quantity of color paste.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

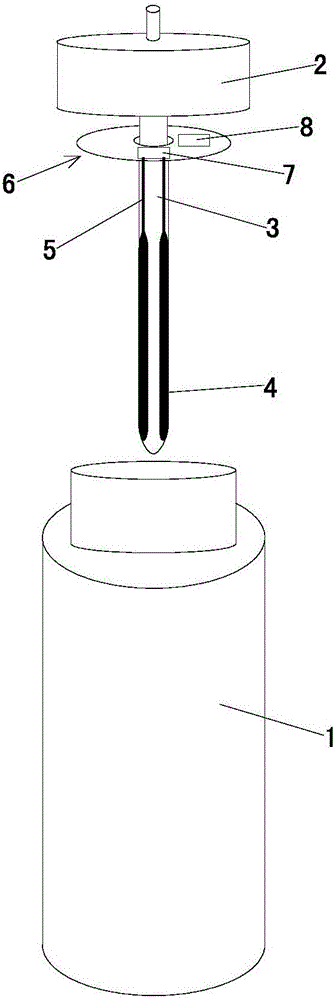

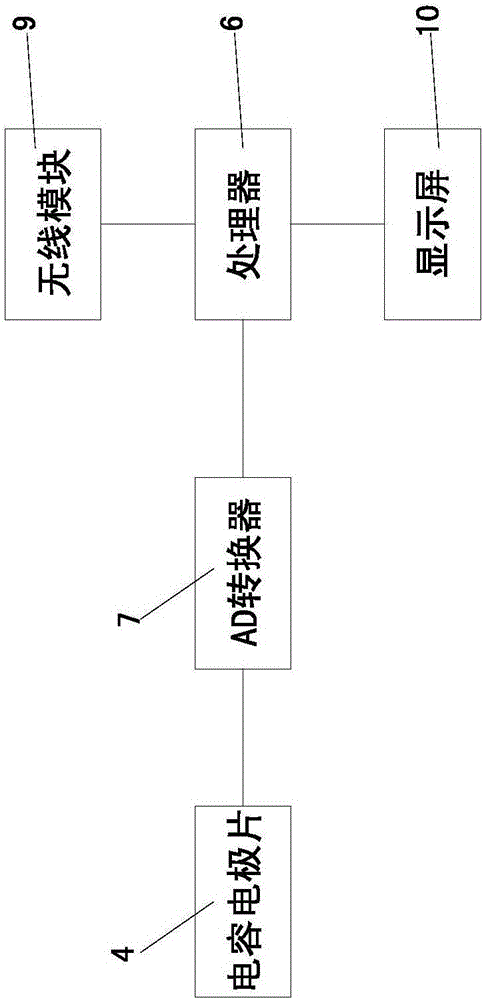

Intelligent straw cup

ActiveCN105996657AEasy to carryPlay a sealing roleThermometers using electric/magnetic elementsUsing electrical meansElectricityWater quality

The invention discloses an intelligent straw cup which comprises a cup body and a cup lid arranged on the cup body. The cup lid is provided with a straw structure stretching into an inner cavity of the cup body. A detection sensor for detecting water quality is arranged on the lower portion of the straw structure in a sealed mode. The lower end of the detection sensor penetrates through the straw structure in a sealed mode. The upper end of the detection sensor is electrically connected with an AD converter and a processor on a PCB through wires integrated in the straw structure. The detection sensor generates electronic signals which are transmitted through the wires to the processor, and the processor processes the signals and converts the signals into digital signals capable of being further processed / used. The PCB is arrange on the upper portion of the straw structure and located at the bottom of the cup lid. According to the intelligent straw cup, the detection mode is not limited, sealing performance is good, production cost of the cup body does not need to be increased, the material of the cup body is not limited, the style design of the cup body is required to be simpler, different cups can be replaced for water quality detection, and the cup is more convenient to use.

Owner:SANCHUAN WISDOM TECH CO LTD

Rubber composition

ActiveUS20110315486A1Excellent adhesion to metalImprove cold resistanceLaminationLamination apparatusPolymer scienceAntioxidant

Disclosed is a rubber composition containing 100 parts by weight of a rubber blend comprising 99-85 by weight % of chloroprene rubber and 1-15 by weight % of chlorinated polyethylene rubber, (A) 10 to 30 parts by weight of a polyether ester-based plasticizer having a molecular weight of 450 to 650, or (B) 10 to 30 parts by weight of both of a polyether ester-based plasticizer having a molecular weight of 450 to 900 and an ester-based plasticizer having a molecular weight 350 to 500, and 3 to 10 parts by weight of two or more aromatic amine-based antioxidants. The rubber composition can simultaneously satisfy requirements for use as, for example, an automobile grease cup material, that is, heat resistance, ozone resistance, cold resistance, and adhesion to metal or resin.

Owner:NOK CORP

High impact-resistance rubber seal cup material

The present invention discloses a high impact-resistance rubber seal cup material, which is prepared from the following raw materials by weight: 460-510 parts of a nitrile butadiene rubber, 50-70 parts of an ethylene-propylene-diene monomer, 5-8 parts of zinc borate, 10-12 parts of antimony trioxide, 2-4 parts of zinc stearate, 3-6 parts of fatty alcohol polyoxyethylene ether phosphate ester, 6-9 parts of triethyl acetylcitrate, 4-6 parts of polydimethylsiloxane, 3-4 parts of nanometer iron brick residue powder, 1-3 parts of sulfur powder, 1-2 parts of antimony trioxide, 1-2 parts of lauryl dimethyl amine oxide, and 10-12 parts of an auxiliary agent.

Owner:WUHU JIACHENG ELECTRONICS TECH

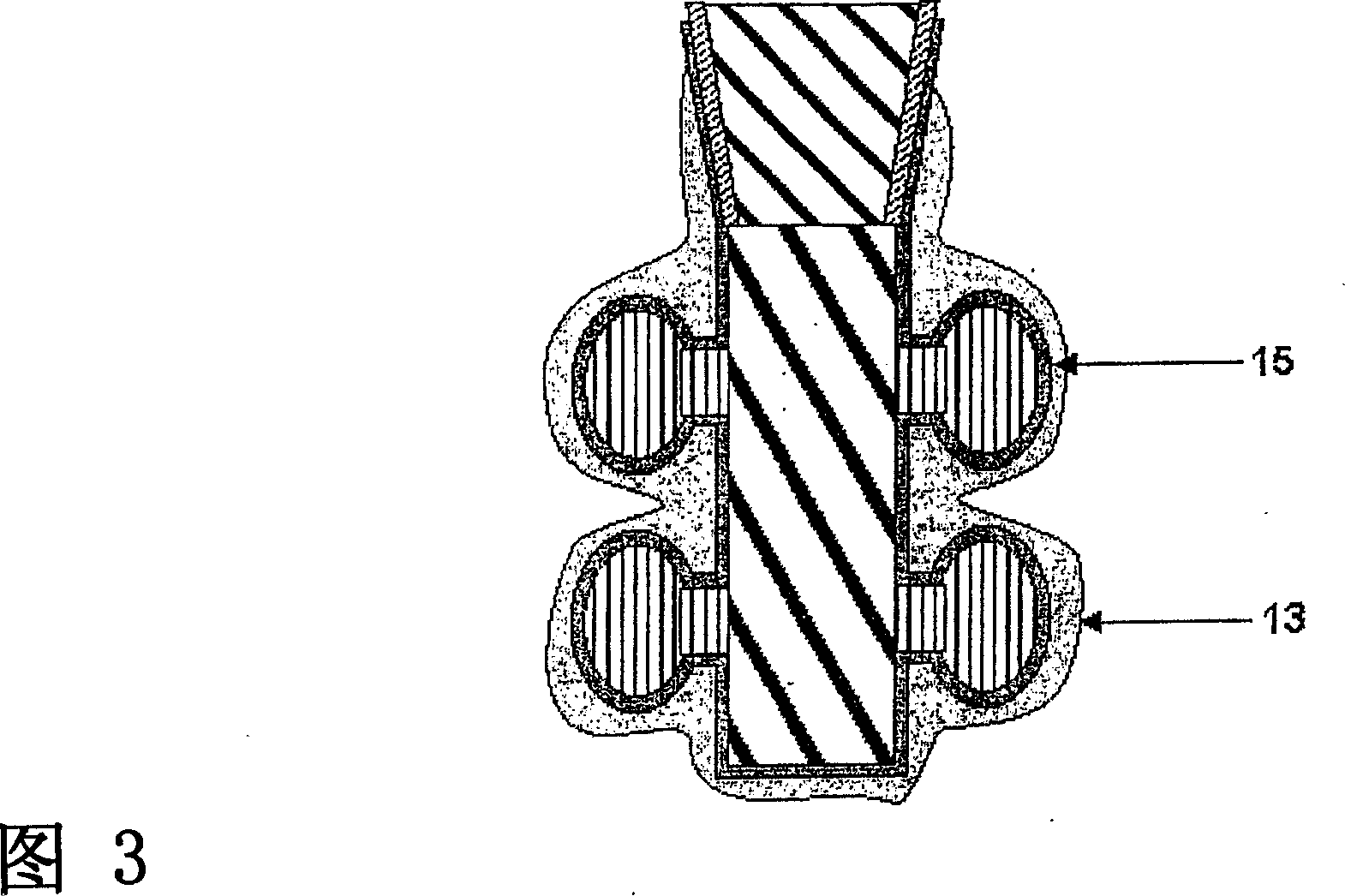

Improvements in investment casting

In an investment casting procedure using microwave energy as the heat source virgin wax models (12) are attached to a spree (10) of a wax-type pattern material incorporating a susceptor, the spree (10) having a pour cup (14) also of a wax-type pattern material, the pour cup material having a higher percentage of the susceptor than the material of the spree. In use the pour cup (14) will melt first and the spree (10) second, unblocking the path of the virgin wax so that its expansion will not crack ceramic with which it has been coated.

Owner:PROCESS TECH EURO

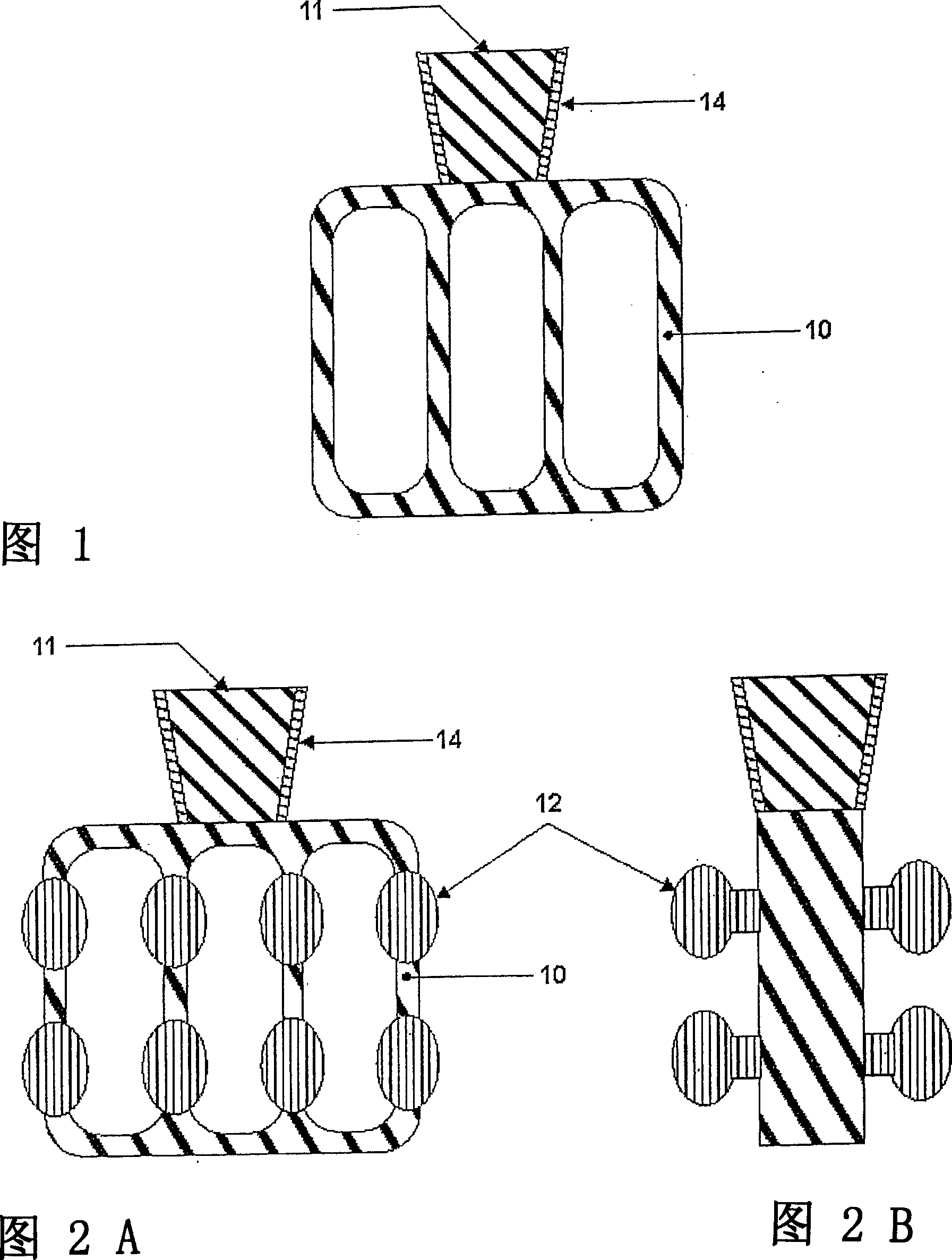

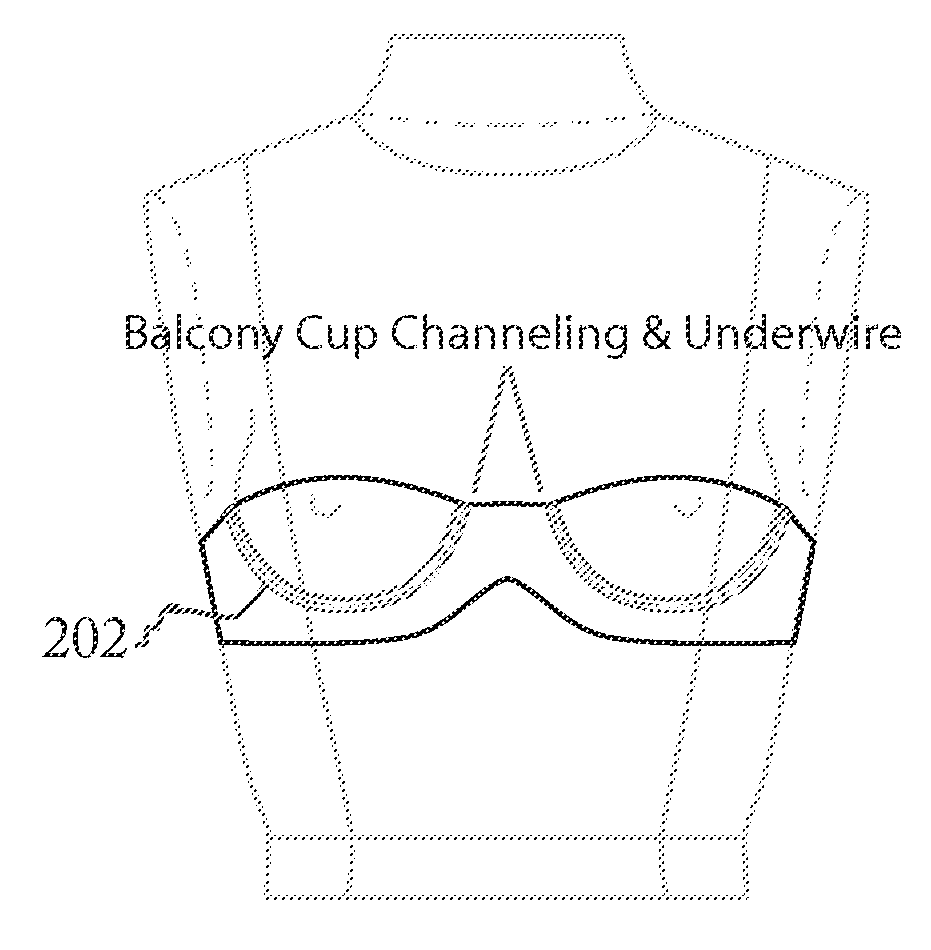

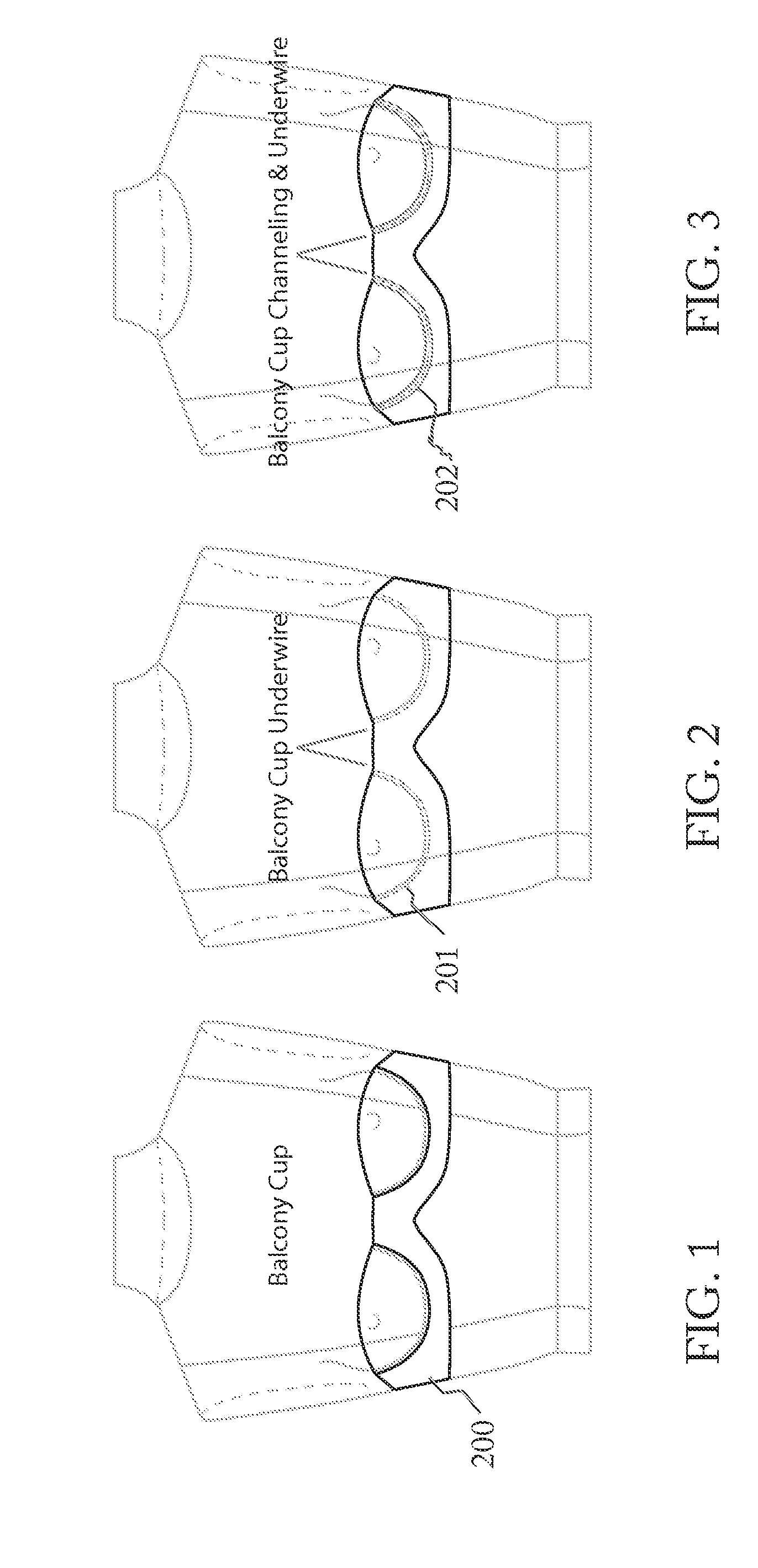

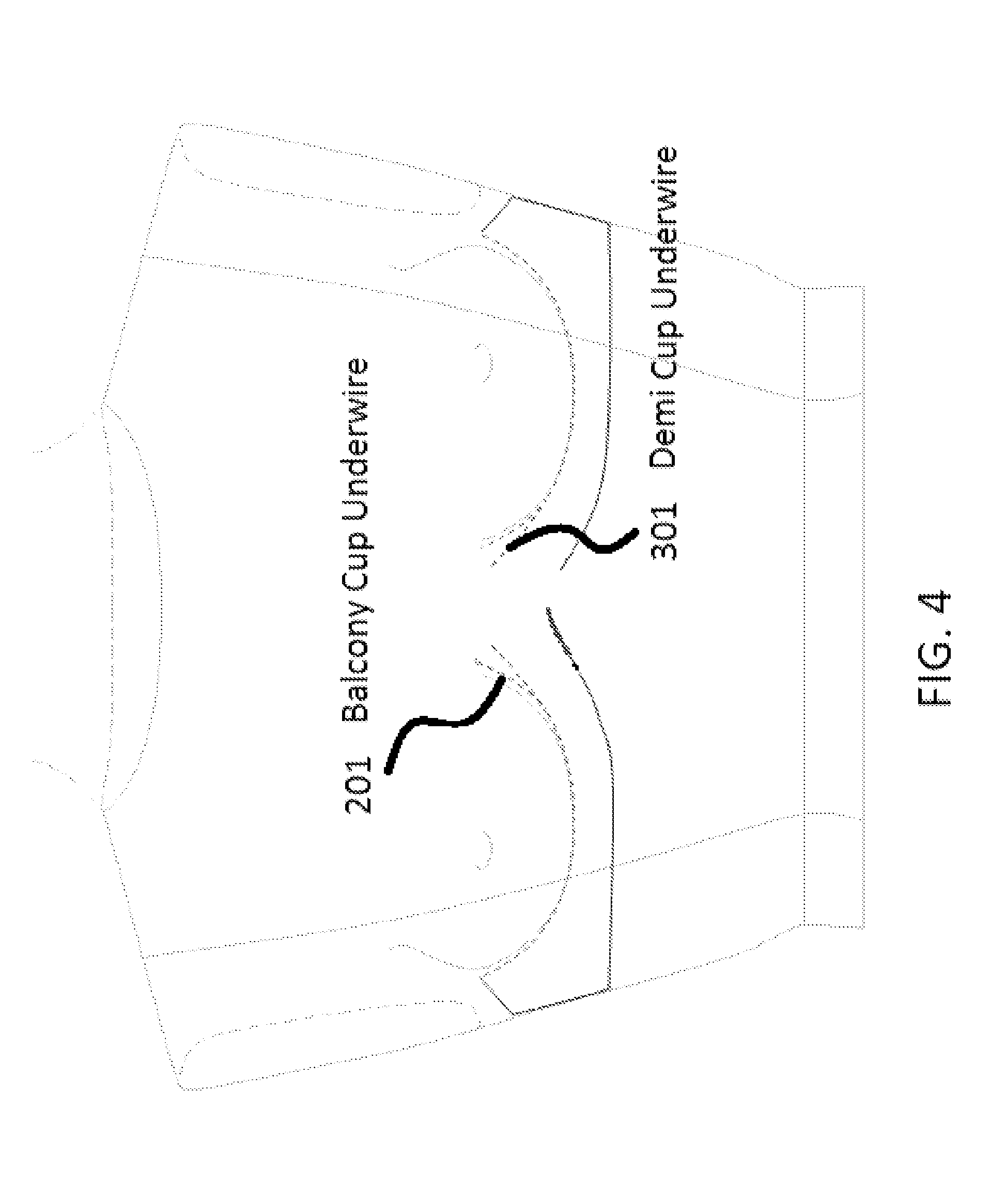

Adjustable Bra System

An adjustable bra system uses pockets 13 on the back side of balcony cups 12 to store demi cup material 11 to convert a demi cup bra to a balcony cup bra. Various bridges connect bra cups together; the bridges include a quick release clasp system 719 allowing the bra cups to quickly spring off the user. Other bridges include the use of offset or staggered 617 receiving snaps allowing for shape adjustment in the bridge area. Bra cups may also have multiple wire channels to accept adjustable wire. The bra cups may also have multiple openings to accept adjustable wire of various lengths.

Owner:DACUMOS SIMEON

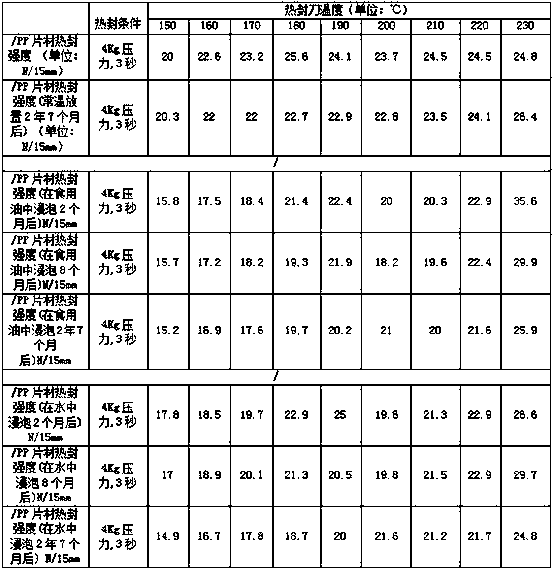

High-temperature steaming and boiling resistant easily-uncovering substrate film, easily-uncovering film containing substrate film and preparation method thereof

PendingCN110126407AEnsure safetyMeet the requirements of sterilizationSynthetic resin layered productsDomestic containersMelt flow indexUltimate tensile strength

The invention belongs to the technical field of packaging materials and specifically relates to an easily-uncovering film. An easily-uncovering substrate film with constant heat sealing strength and with a seal firmly sealed successively comprises a corona layer, an intermediate layer and a heat sealing layer from the outside to the inside that are co-extruded. The material of the corona layer isa blend of PP and metallocene HDPE. The weight ratio of PP to metallocene HDPE is 20-50: 100. The material of the intermediate layer is metallocene HDPE, and the melt index is 0.5-1 g / 10 min. The material of the heat sealing layer is an ethylene-propylene-butylene ternary copolymer. When the film of the invention is heat-sealed with a pp cup material, heat sealing strength is 15-29 N / 15 MM under the precondition of satisfying food safety, it is convenient for consumers to uncover the film and use, and the film can resist steaming and boiling of 121 DEG C.

Owner:惠州德昉高分子膜材料有限公司

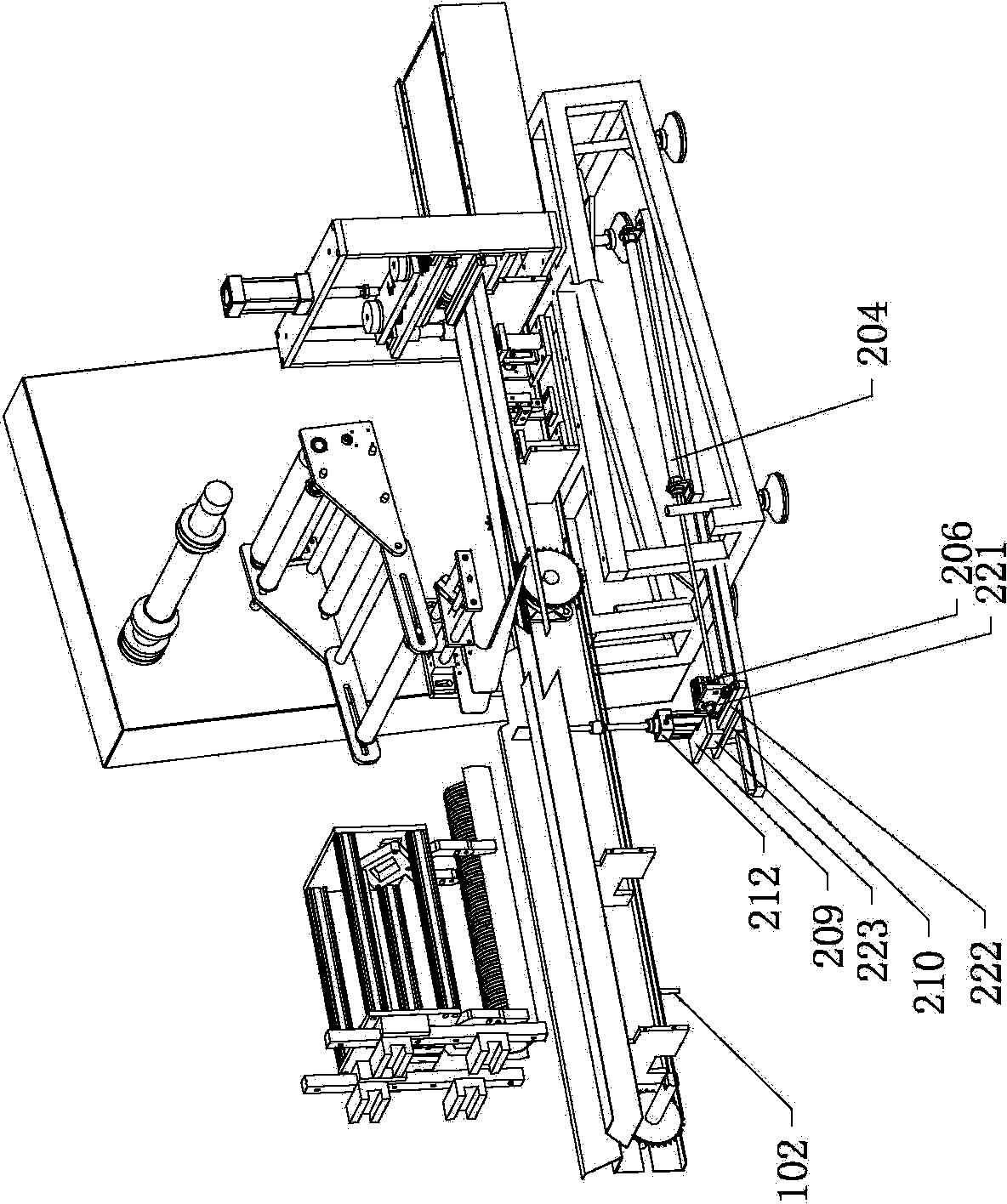

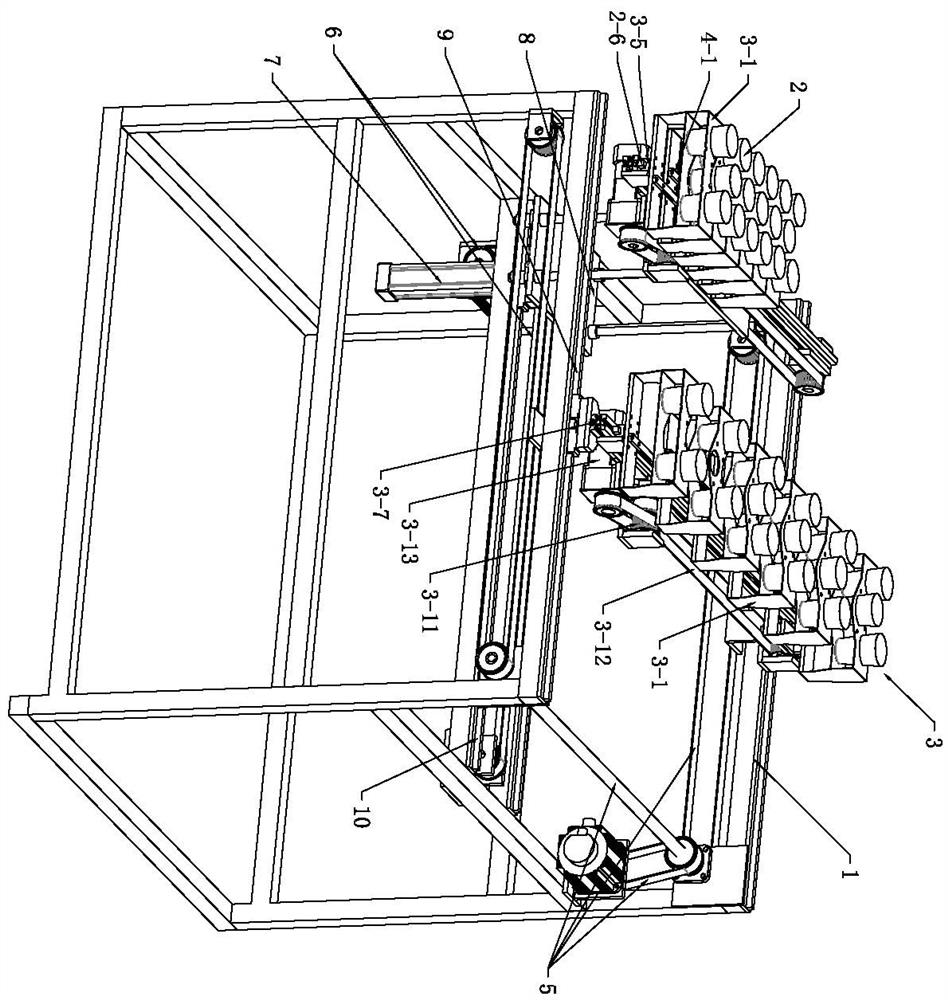

Telescopic receiving, stacking and unloading device with AB units achieving telescopic motion and alternate work

The invention relates to a telescopic receiving, stacking and unloading device with AB units achieving telescopic motion and alternate work. The telescopic receiving, stacking and unloading device comprises a support and two receiving and stacking units, each receiving and stacking unit comprises a plurality of material receiving brackets, a telescopic supporting piece, a telescopic sliding rail and a telescopic driving device. The telescopic receiving, stacking and unloading device with the AB units achieving telescopic motion and alternate work is provided with the two receiving and stackingunits which can achieve alternate material receiving, and the working efficiency is high; and the multiple material receiving brackets of each receiving and stacking unit can be spliced into a whole,the upper portions of the material receiving brackets are provided with a plurality of material receiving openings used for receiving and stacking cup materials, when the multiple material receivingbrackets are unfolded, the material receiving brackets can be in butt joint with material taking and unloading mechanical arms to receive and stack products, after the products are received and stacked, the multiple material receiving brackets can be folded and spliced into the whole, and at the time, the plurality of material receiving brackets correspond to transfer conveying mechanical arms.

Owner:王昌佑

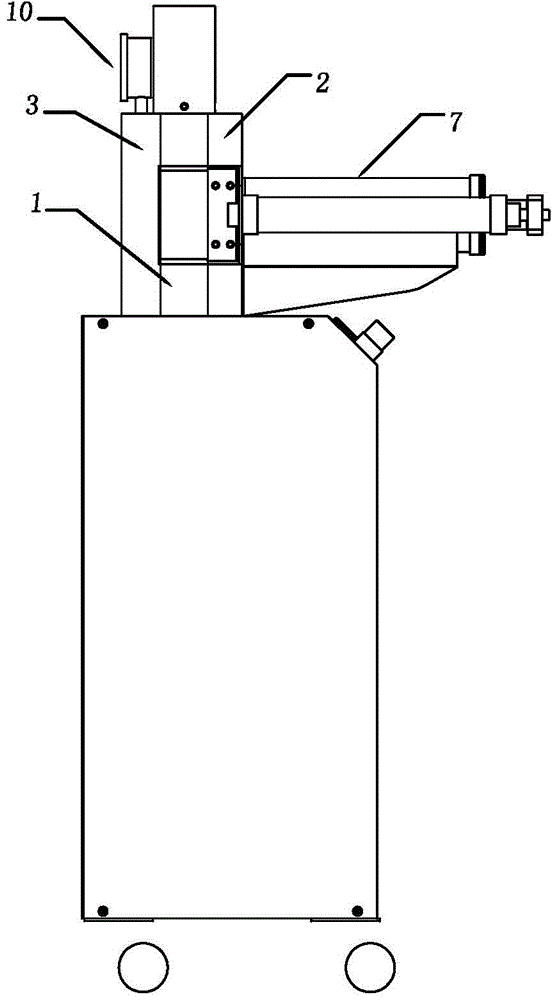

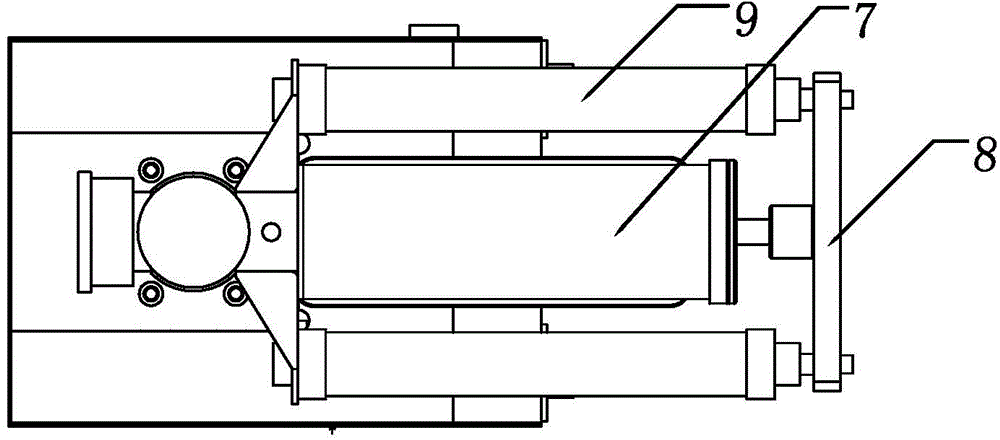

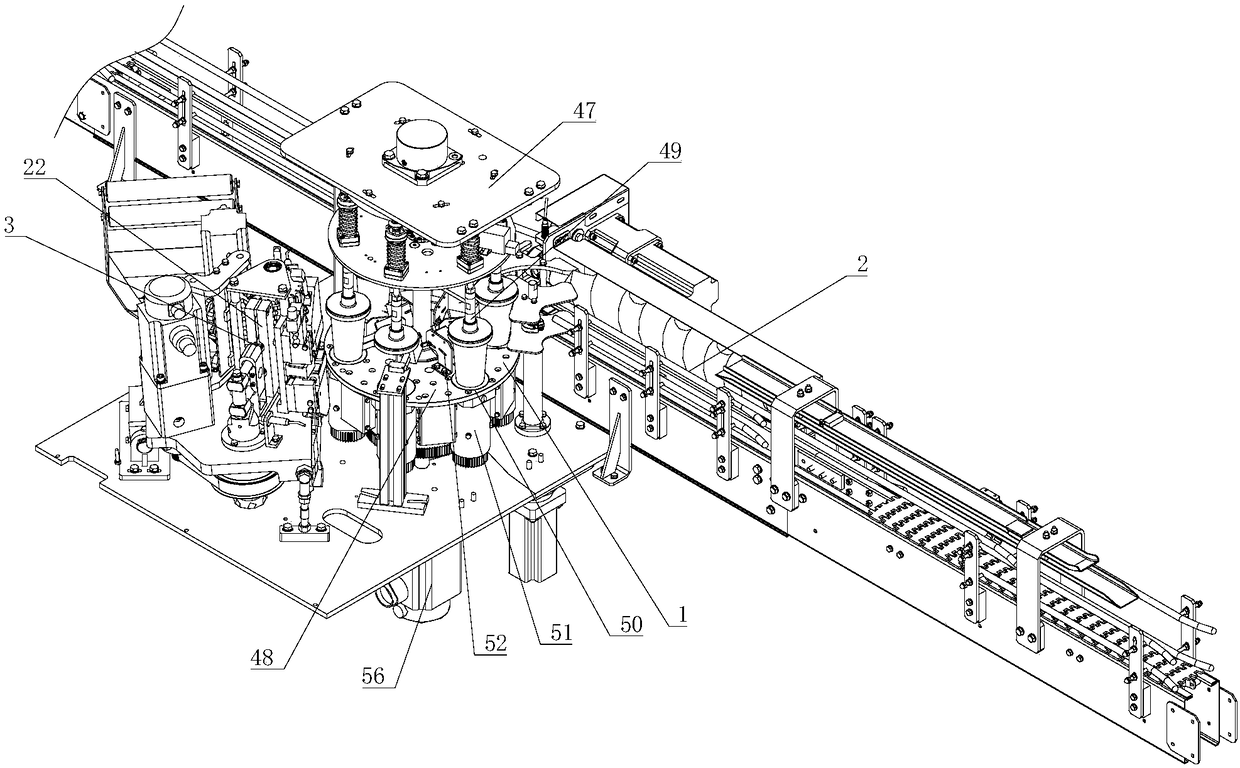

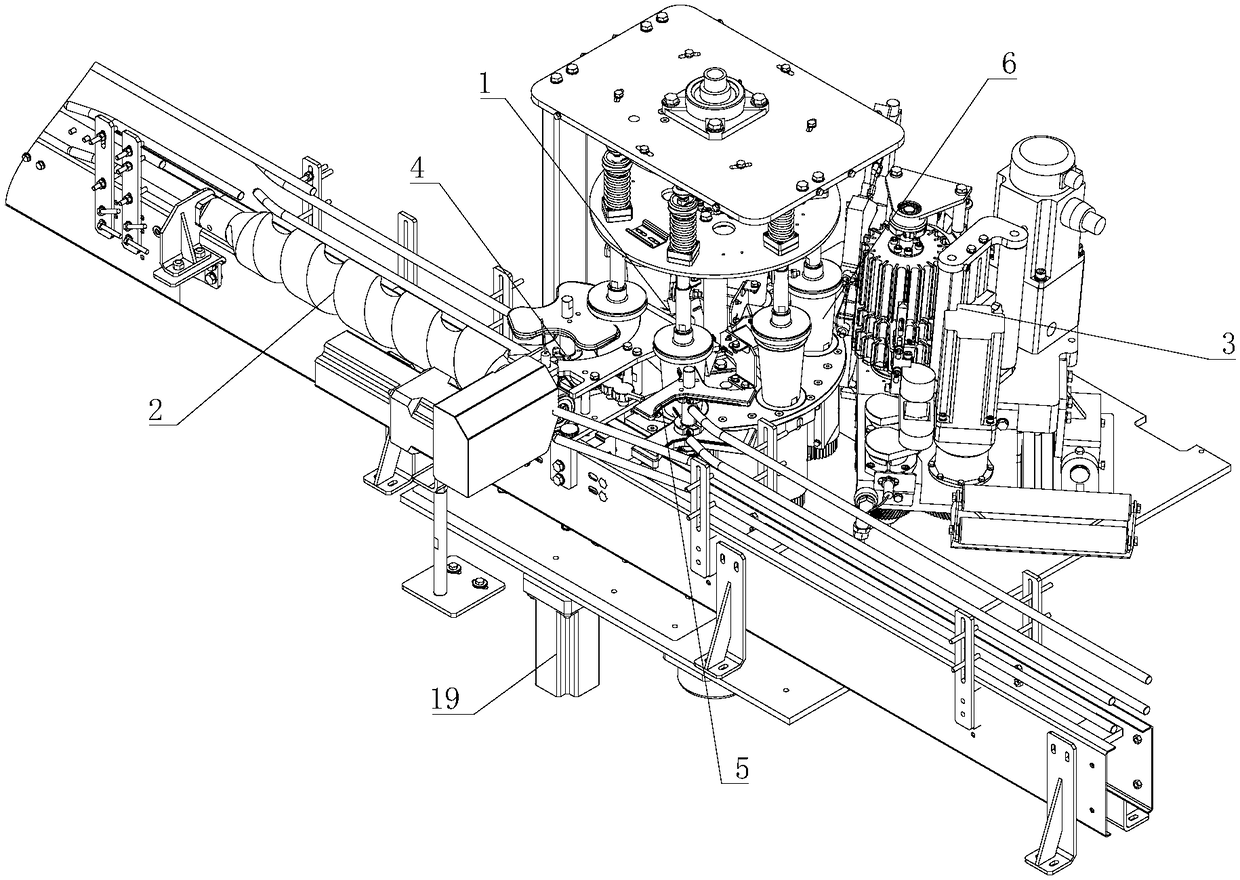

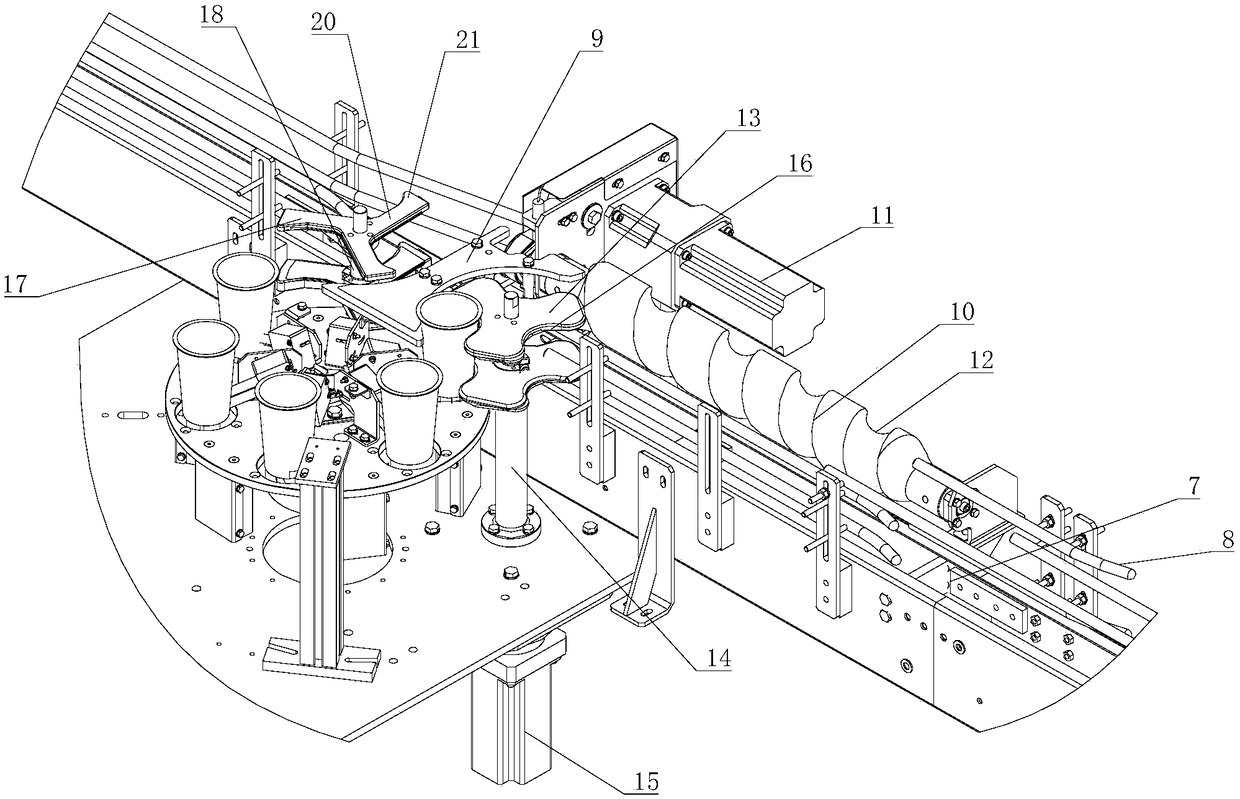

Continuous pipe pasting device

A continuous pipe pasting device comprises a cup rotating device, a cup material conveying device and a pipe pasting device body. The cup rotating device is provided with a feeding port, a dischargingport and a plurality of stations arranged in the circumferential direction. The stations conduct revolution around a center shaft. The cup rotating device can drive cup materials positioned on the stations to do the self-rotation movement, and the cup materials stop self-rotation after conducting self-rotation to the specific positions. The cup material conveying device is arranged on one side ofthe feeding port and the discharging port of the cup rotating device and is used for sequentially conveying the cup materials to the stations of the cup rotating device, and the cup materials obtained after pipe pasting are conveyed out of the stations. The pipe pasting device body is arranged on the side, deviating from the feeding port and the discharging port, of the cup rotating device and isused for conducting the pipe pasting procedure on the cup materials positioned through the cup rotating device. The continuous pipe pasting device has the beneficial effects that adaptability is high, the error-tolerant rate for products is high, and the continuous pipe pasting device can be applicable to different sizes of products only through simple modification.

Owner:广州市铭慧机械股份有限公司

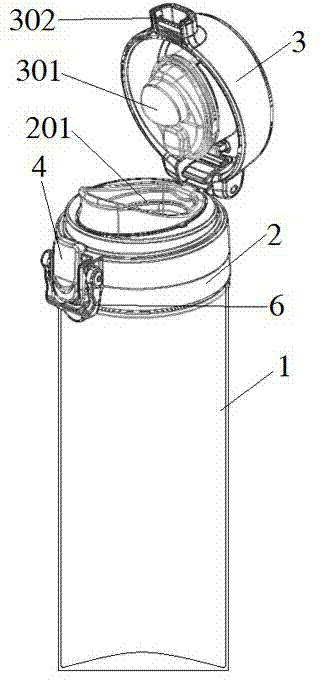

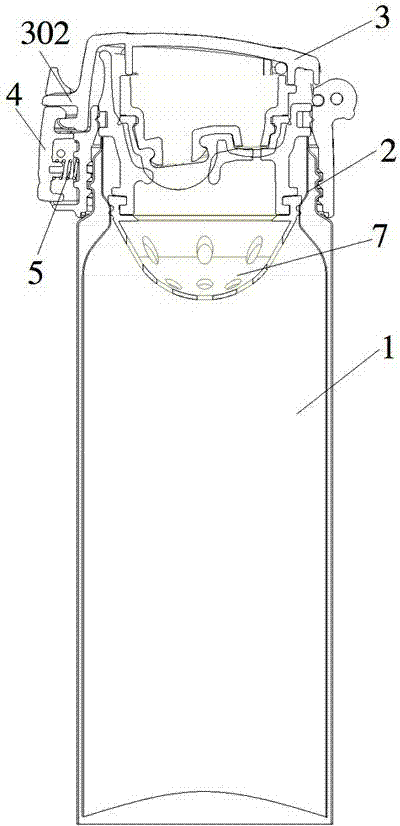

Drinking cup

InactiveCN102885548AAchieve one-handed operationPrevent openingDrinking vesselsThermal insulationEngineering

The invention discloses a drinking cup comprising a cup body and a cap body assembly; the cap body assembly comprises a bottom cap and a top cap which are hinged with each other; the bottom cap is rotationally arranged on the top of the cup body and is provided with a water outlet; a sealing part used for sealing the water outlet is arranged in the top cap; the bottom cap is provided with an elastic buckle; the top cap is provided with a buckling part which is matched with the elastic buckle; the bottom cap is further provided with a rotating buckle used for locking the buckling part; and a filter screen which is connected to the inner wall of the bottom cap in a clamping way is also arranged below the bottom cap. The drinking cup has the following benefits that the purpose of operating the bottom cap and the top cap by single hand is fulfilled conveniently with the cooperation of the elastic buckle and the buckling part; meanwhile, the rotating buckle is also arranged for locking the buckling part, so that the situation of opening the top cap by error operation is avoided; the filter screen connected to the inner wall of the bottom cap in the clamping way and arranged below the bottom cap is convenient for drinking tea or other drinking tablets; the cup body is made of transparent double-layer hollow glass, thereby having the following characteristics of anti-scalding, thermal insulation and direct viewing; and the drinking cup can effectively ensure that the effective components of the tea cannot be changed by long-time high temperature when tea is made.

Owner:苏州昆兰家居用品有限公司

Sample quantization and rapid detection equipment for food quality detection

The invention discloses sample quantization and rapid detection equipment for food quality detection. The equipment comprises a base, wherein a bracket is mounted on the base; a sample storage barreland an elution box with multiple compartments are arranged on the bracket; a water storage box is integrally made on the side of the elution box; a metering valve is arranged at the bottom of the sample storage barrel, the bottom of the water storage box and the bottom of each compartment of the elution box; the metering valves are connected to a guide-in pipe; the guide-in pipe is connected to abuffer cup mounted below the sample storage barrel by virtue of a feed pump; a dropping head is arranged at the bottom of the buffer cup; a conveyor belt driven by a stepping motor is arranged on thebase and just under the buffer cup; a plurality of detection cups are arranged on the outer surface of the conveyor belt at intervals; and ultraviolet generation and detection assemblies are fixed onthe base on two sides of the detection cups. According to the sample quantization and rapid detection equipment for food quality detection disclosed by the invention, a certain component in the sampleis measured in a single manner, so that the food sample quality can be judged.

Owner:苏州市苏测检测技术有限公司

Inflaming retarding and low temperature resistant packing cup material

The invention discloses an inflaming retarding and low temperature resistant packing cup material which is prepared from the following raw materials in parts by weight: 70-80 parts of nitrile rubber, 35-40 parts of silicone rubber, 12-15 parts of acrylic ester, 4-6 parts of chlorinated paraffin, 4-7 parts of dioctyl phthalate, 2-3 parts of a silane coupling agent KH560, 1-2 parts of microcrystalline wax, 0.4-1.2 parts of an anti-aging agent NBC, 0.5-1 part of an accelerant DM, 1-2 parts of smoke sheet rubber, 1-2 parts of sulphur, and 10-12 parts of an addition agent; the packing cup manufactured through the material is applied to the demanding fields, the rubber is mixed fully, and the material has the advantages of inflaming retarding, no smoke, and excellent low temperature effect.

Owner:WUHU JIACHENG ELECTRONICS TECH

Heating and thermal insulating pouring cup and manufacturing method thereof

The invention discloses a heating and thermal insulating pouring cup and a manufacturing method thereof. The heating and thermal insulating pouring cup is characterized in that a pouring cup material is formed by a heating material and a thermal insulating material through a bonding material, the thermal insulating material is formed by asbestos, refractory sand and refractory fibers, the heating material is formed by aluminite powder, silica powder and iron oxide powder, and the bonding material is resin and a hardening agent. The pouring cup material comprises that the thermal insulating material comprises, by weight, 70%-80% of the refractory sand, 3%-5% of the refractory fibers and 3%-5% of the asbestos; the heating material comprises, by weight, 6%-9% of the aluminite powder, 6%-9% of the silica powder and 1%-2% of the iron oxide powder; the bonding material comprises, by weight, 6%-8% of the resin and 3%-4% of the hardening agent. According to the pouring cup, it is guaranteed that casting liquid can be continuously heated, thermal insulating can be achieved, the shrinkage and air holes in the casting forming process can be lowered, the finished casting product rate and the casting quality are increased, and the casting yield is increased.

Owner:HUBEI YAGANG METAL MFR

Heating-forming polysiloxane composition for LED (light emitting diode) components

The invention relates to a polysiloxane and functional filler composition which can be hardened and formed by heating. The composition comprises (A) reticular or chain polysiloxane containing alkenyl, (B) reticular or chain polysiloxane containing hydrogen group, (C) various heat conducting, flame retardant, aging resistant and temperature resistant functional fillers, and (D) catalysts which contain alkenyl and are used for hydrogen group silylation reaction. The siloxane composition which can be hardened and formed by heating is suitable for formulas of bases or lamp cup materials of LED devices and can have excellent thermo shock resistance synchronized with the LED bases or lamp cups, resistance to cracks between the LED bases or lamp cups and the lamp cups, heat dissipation property, flame retardance and aging resistance.

Owner:矽时代材料科技股份有限公司

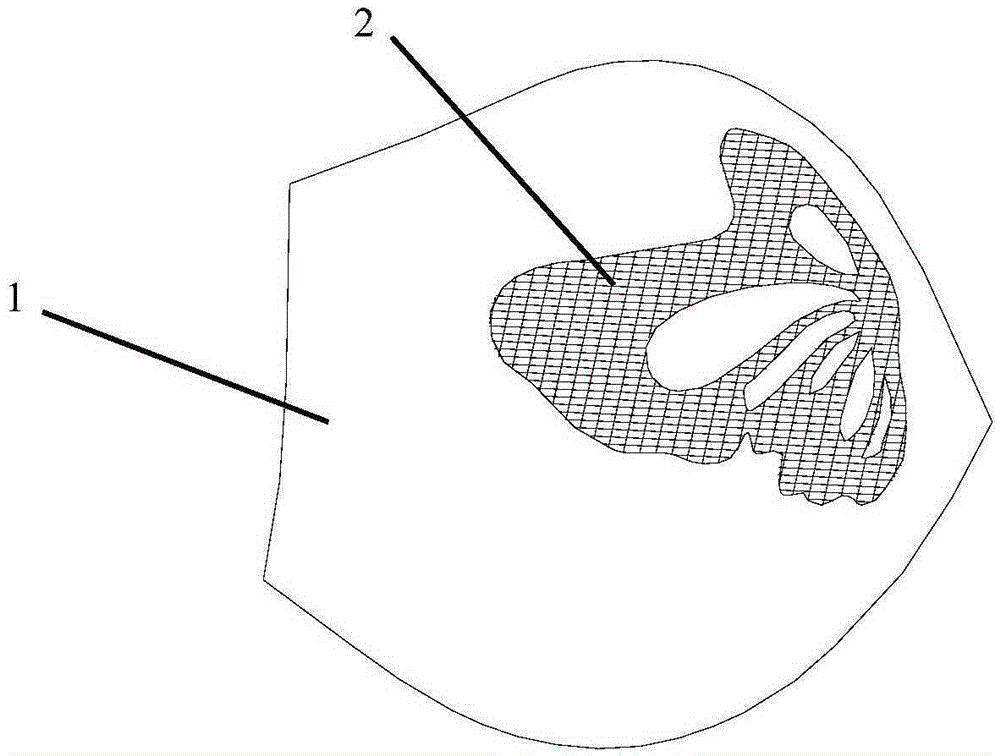

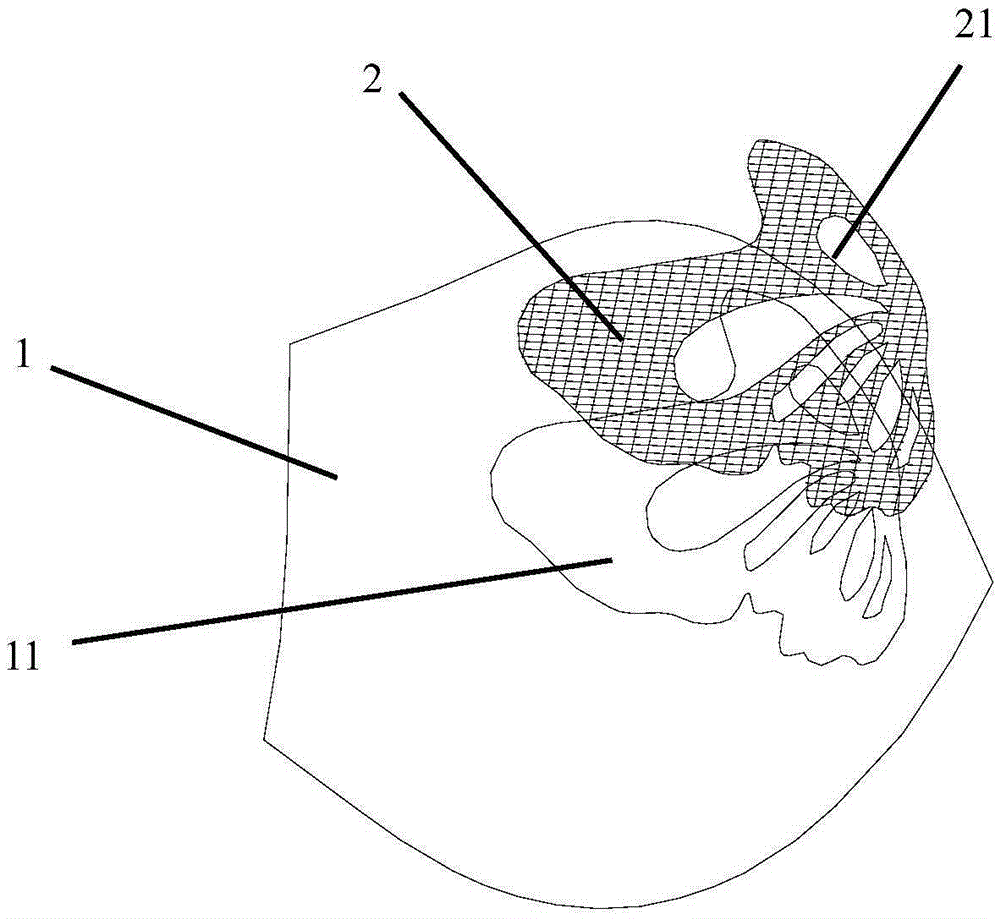

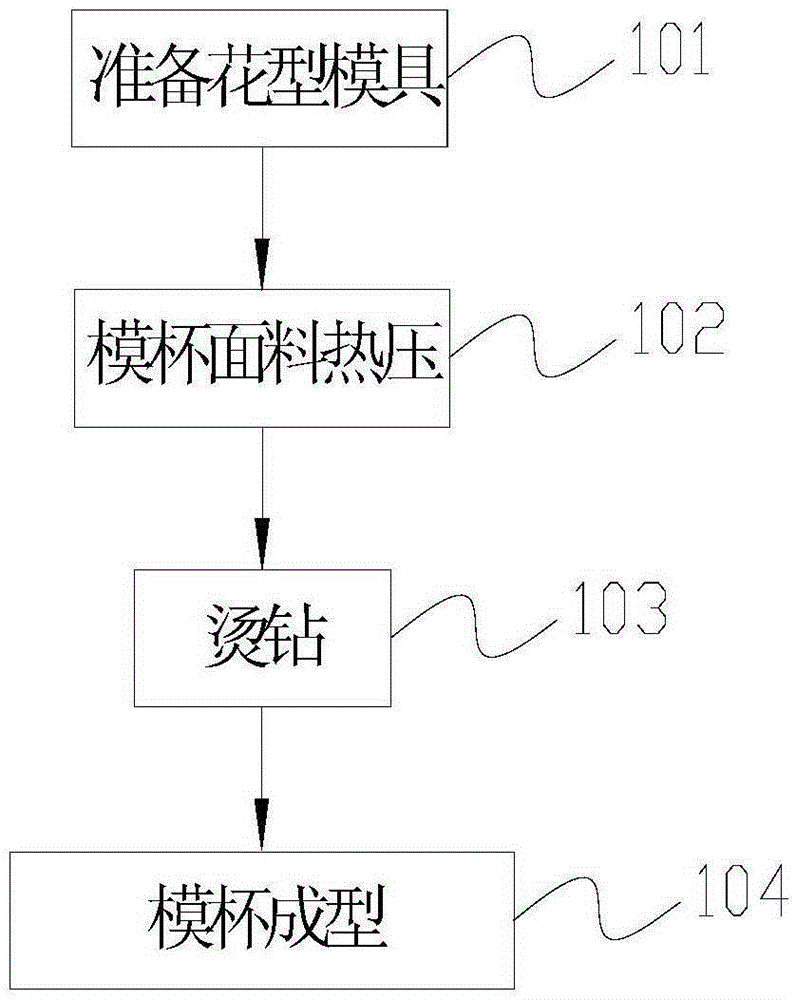

Hot melt adhesive net diamond die cup and manufacturing method therefor

The invention discloses a hot melt adhesive net diamond die cup. The net diamond die cup comprises a die cup body and also comprises sheet-shaped hot melt adhesive net diamond fixed on the cup surface of the die cup body. A pit matching the hot melt adhesive net diamond in shape is arranged in the cup surface of the die cup body. The hot melt adhesive net diamond is inlaid in the pit. The invention also discloses a manufacturing method for the die cup. The method comprises steps: firstly, a flower-shaped die is prepared, namely, a flower-shaped die with the same shape as the hot melt adhesive net diamond is engraved by a metal sheet; secondly, a die cup fabric hot pressing is carried out, namely, a pit is formed in the surface of the die cup fabric through hot pressing; thirdly, diamond scalding is carried out, namely, the hot melt adhesive net diamond is inlaid and combined in the pit of the die cup fabric through the heat bonding effect, thus the hot melt adhesive net diamond fills the pit, and a diamond scalding die cup material is obtained; fourthly, die cup forming is carried out, namely, the diamond scalding die cup material is subjected to molding as a whole and a shaped die cup is obtained. The hot melt adhesive net diamond inlaid die cup has a smooth surface, looks bright and clean, and wears comfortable and beautiful.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

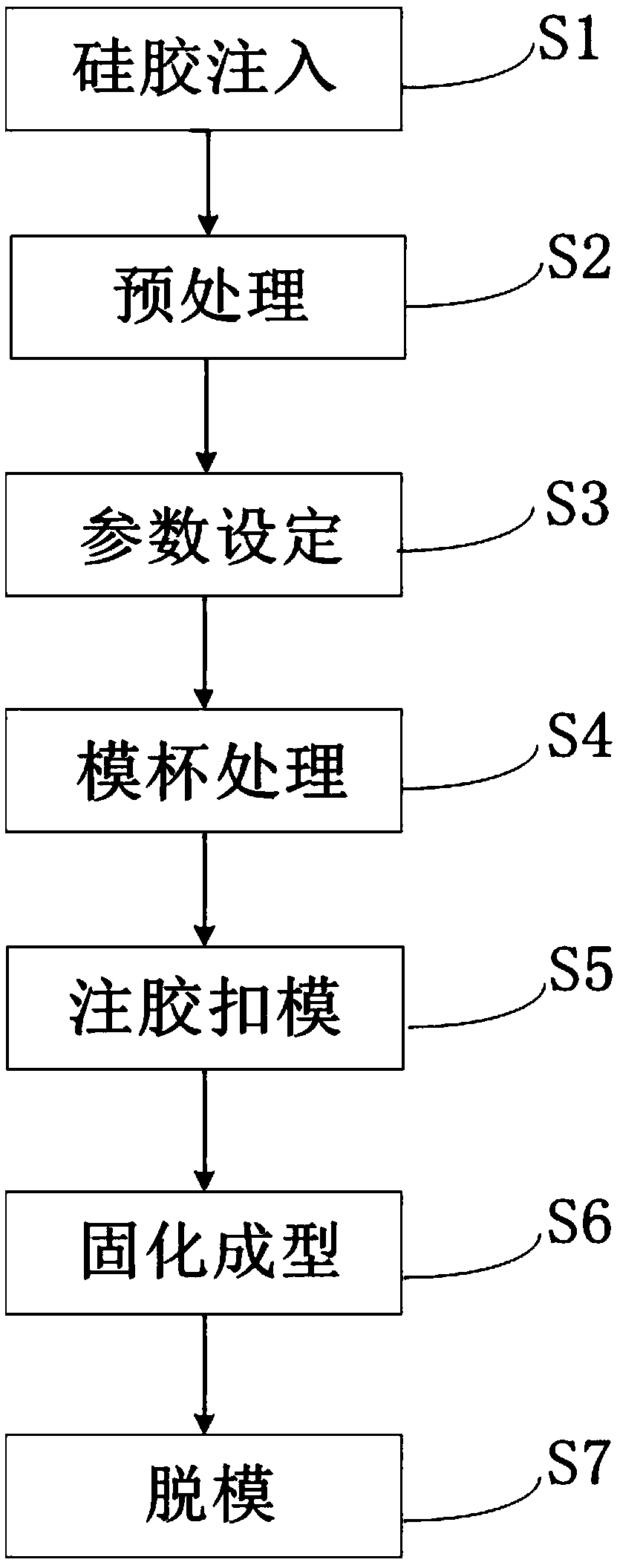

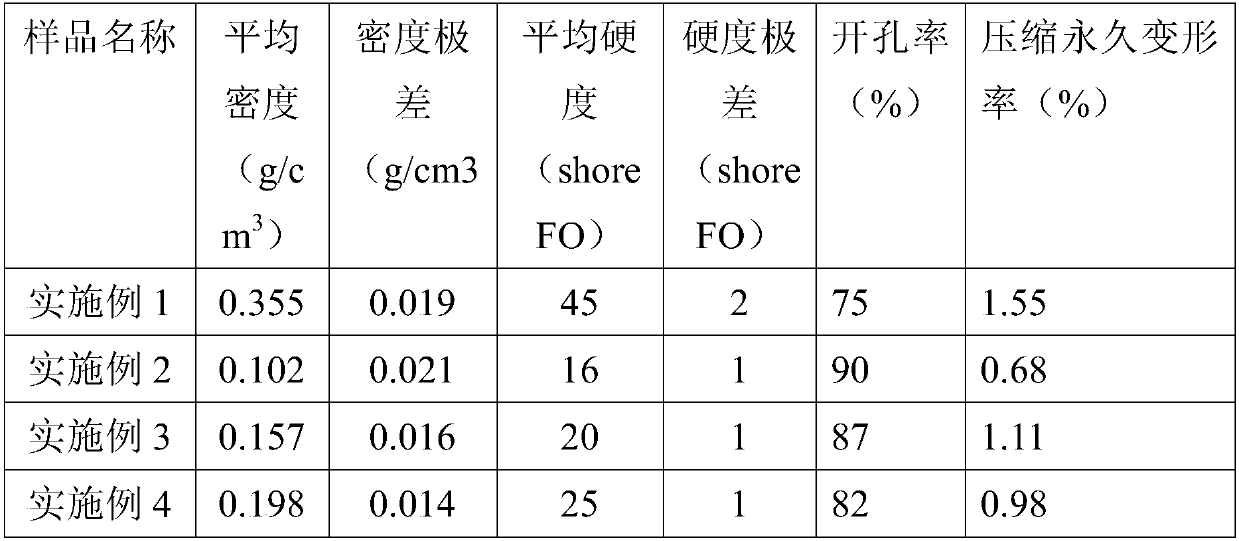

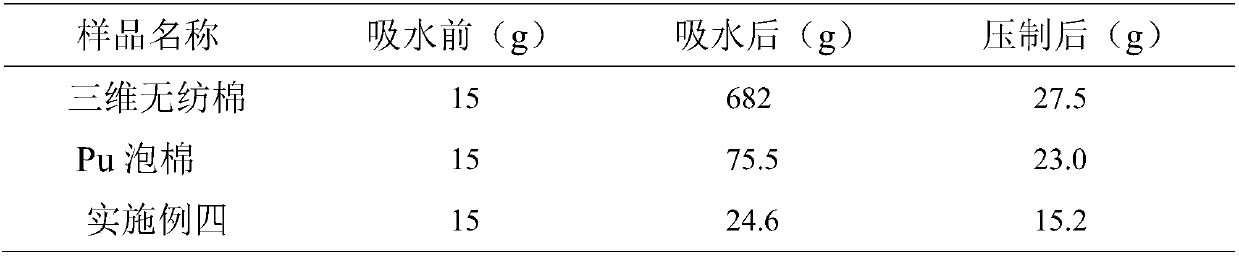

Preparation method of foam material for bra

The invention relates to the field of underwear production, particularly to a preparation method of a foam material for a bra. The preparation method comprises the following steps: respectively conveying an organic silica gel A containing a foaming component and an organic silica gel B containing a foaming component to the channel A and the channel B of a glue injection machine; keeping the organic silica gel A and the organic silica gel B at a constant temperature to a pretreatment working temperature to prepare before gel injection; uniformly stirring and mixing the organic silica gel A andthe organic silica gel B; setting glue injection parameters; starting the glue injection machine, injecting the uniformly mixed silica gel into the female die of a mold cup, buckling a male die, locking the female die and the male die, turning over the mold cup, and foaming; and after the foaming is finished, opening the mold cup, and taking out the foam material. By adopting the method disclosedby the invention, the organic silicon foam mold cup material with characteristics of uniform foaming, low density, high aperture ratio, soft hand feeling and stable quality can be obtained through one-time foaming molding.

Owner:嘉兴未来新材料科技有限公司

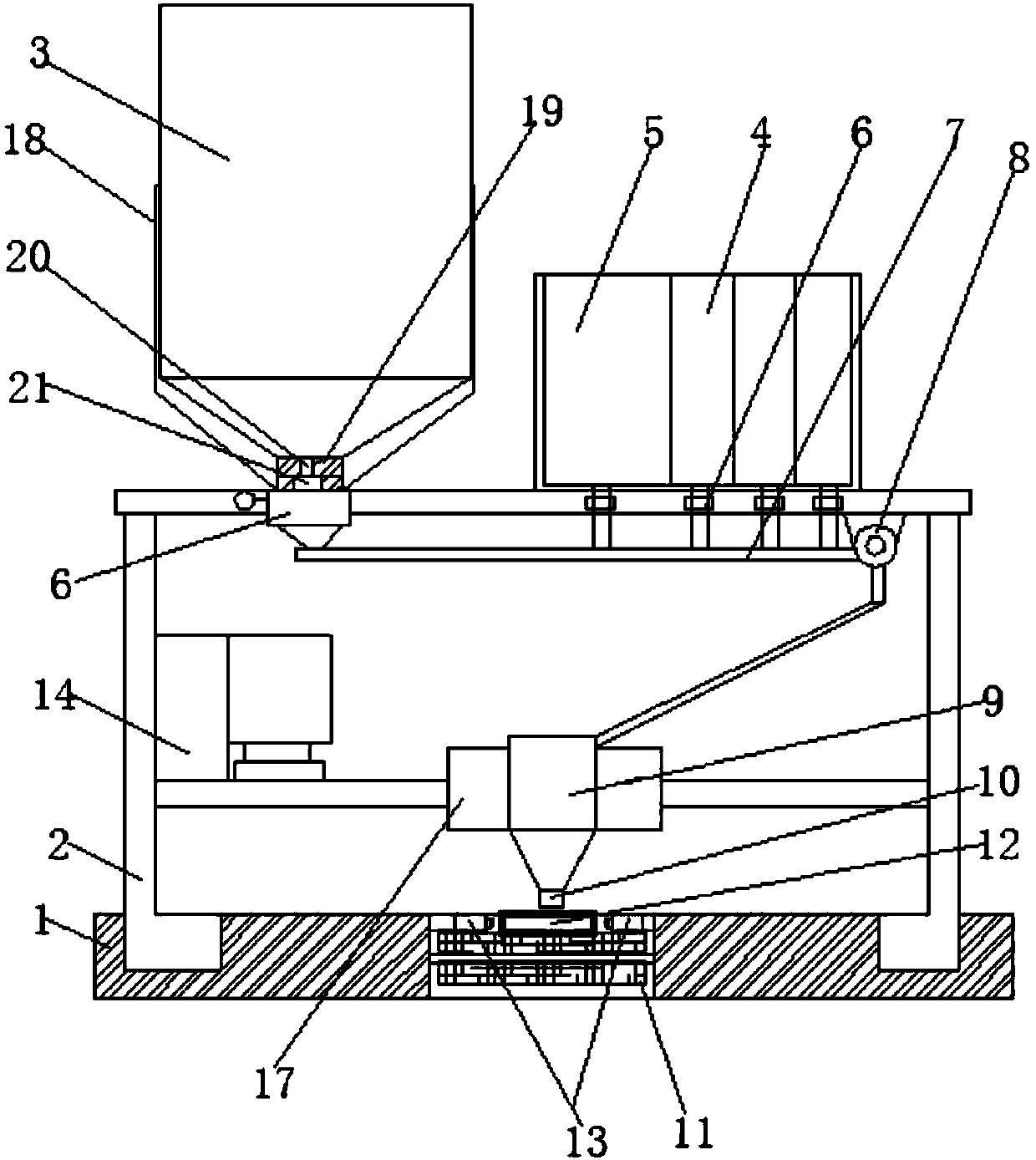

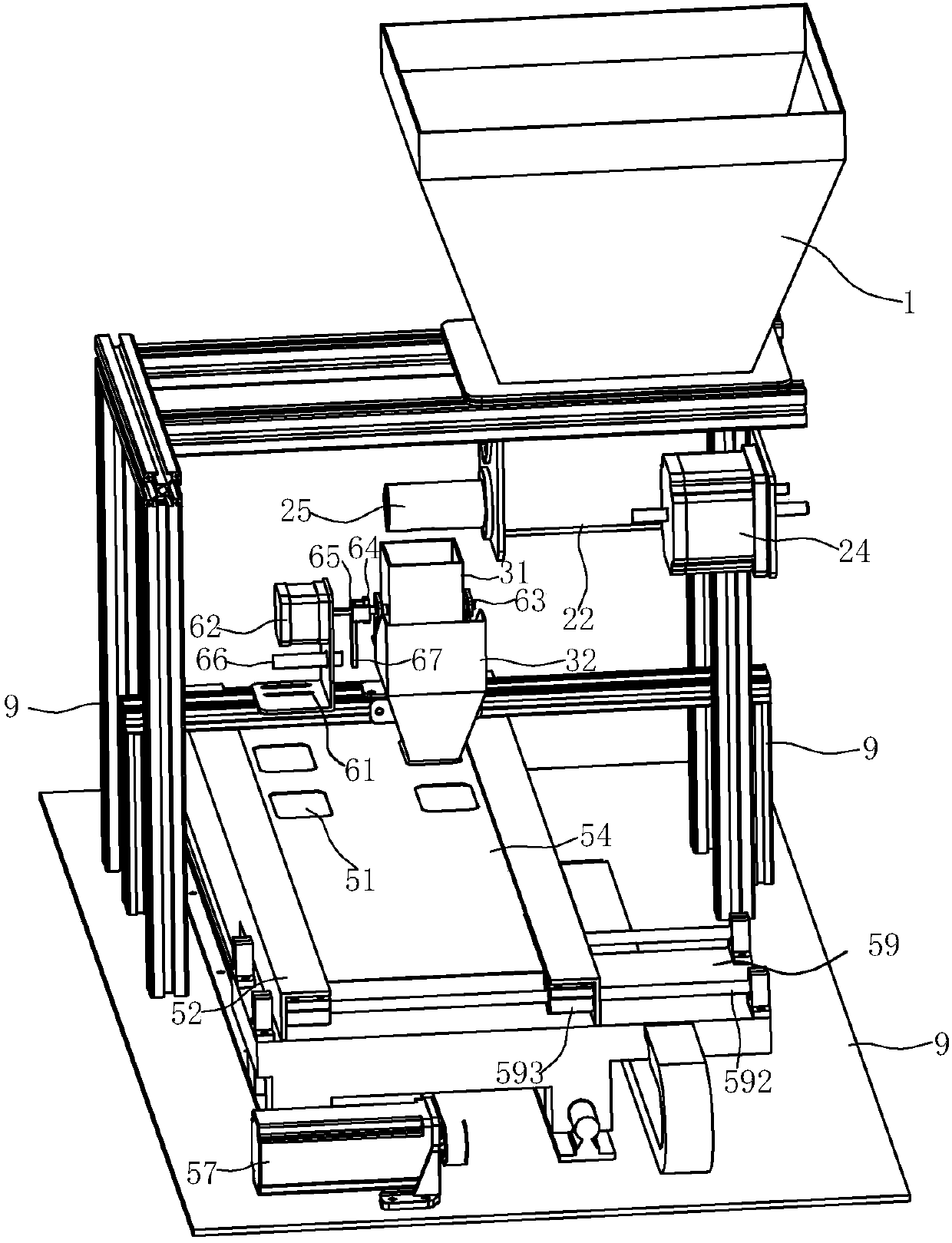

Automatic powder weighing machine

PendingCN107782427AAvoid residueAvoid compromising final product qualityWeighing apparatus for materials with special property/formEngineeringLoad cell

The invention relates to an automatic powder weighing machine. The automatic powder weighing machine comprises a stander, a material storing bucket, a material conveying mechanism and a weighing assembly, wherein the material storing bucket, the material conveying mechanism and the weighing assembly are sequentially arranged on the stander from top to bottom. The automatic powder weighing machineis characterized in that the weighing assembly comprises a material weighing cup and a weighing sensor, wherein the weighing sensor is arranged at the bottom of the material weighing cup and is used for weighing powder in the material weighing cup. According to the automatic powder weighing machine, the weighing sensor is arranged at the bottom of the material weighing cup and only bears the sum of the weight of the material weighing cup and the set weight of the powder quantitatively output each time, and only a small-range weighing sensor is selected, so that the weighing precision is improved; the weighing sensor and the feeding mechanism are separated, so that the influence caused by the vibration of the motor to the weighing sensor during the rotation of the motor is avoided, and theweighing precision is improved; and the range of the weighing sensor is not limited, more powder can be added into the material storing bucket at one time, and the powder does not need to be frequently added, so that the operation is convenient, and the automation degree is high.

Owner:闵杰

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com