Telescopic receiving, stacking and unloading device with AB units achieving telescopic motion and alternate work

A technology of unloading device and receiving platform, which is applied in packaging and other directions, can solve the problems of expensive molds, many movements, and low-grade products, and achieve the effects of smooth equipment operation, high work efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

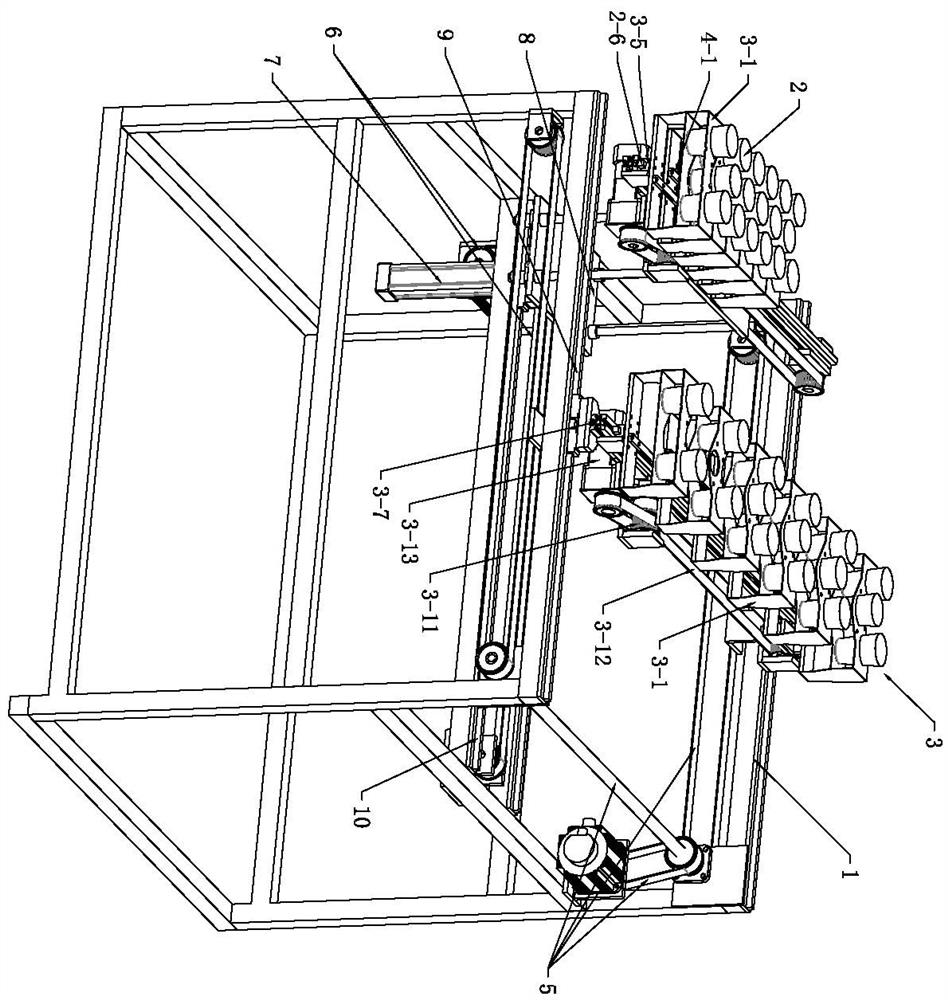

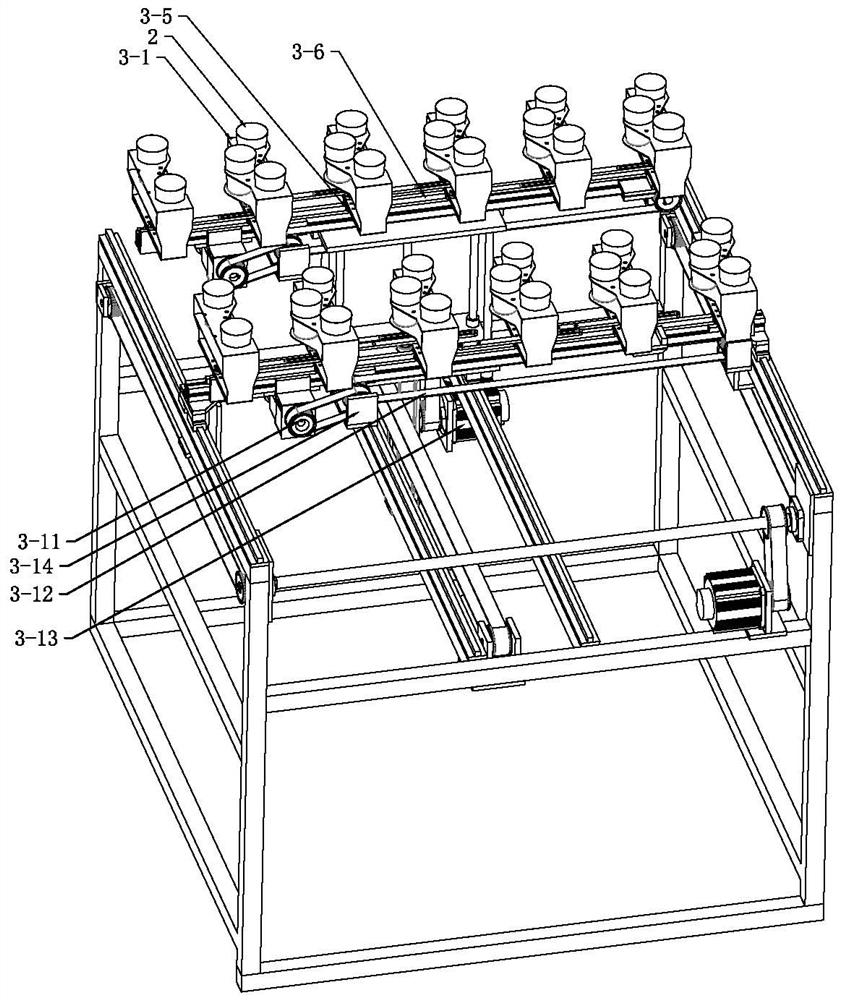

[0062] see figure 1 and Figure 10 The telescopic and alternate telescopic stacking and unloading device of the AB unit of this embodiment includes a bracket 1 and two stacking units, and the stacking unit includes a plurality of material receiving brackets 3-1, telescopic support members 3-7, telescopic slides Rail 3-6 and telescopic driving device, the bottom of receiving bracket 3-1 is fixedly connected with slide block 3-5, and slide block 3-5 is slidably arranged on telescopic slide rail 3-6, and telescopic slide rail 3-6 is installed on Telescopic supports 3-7.

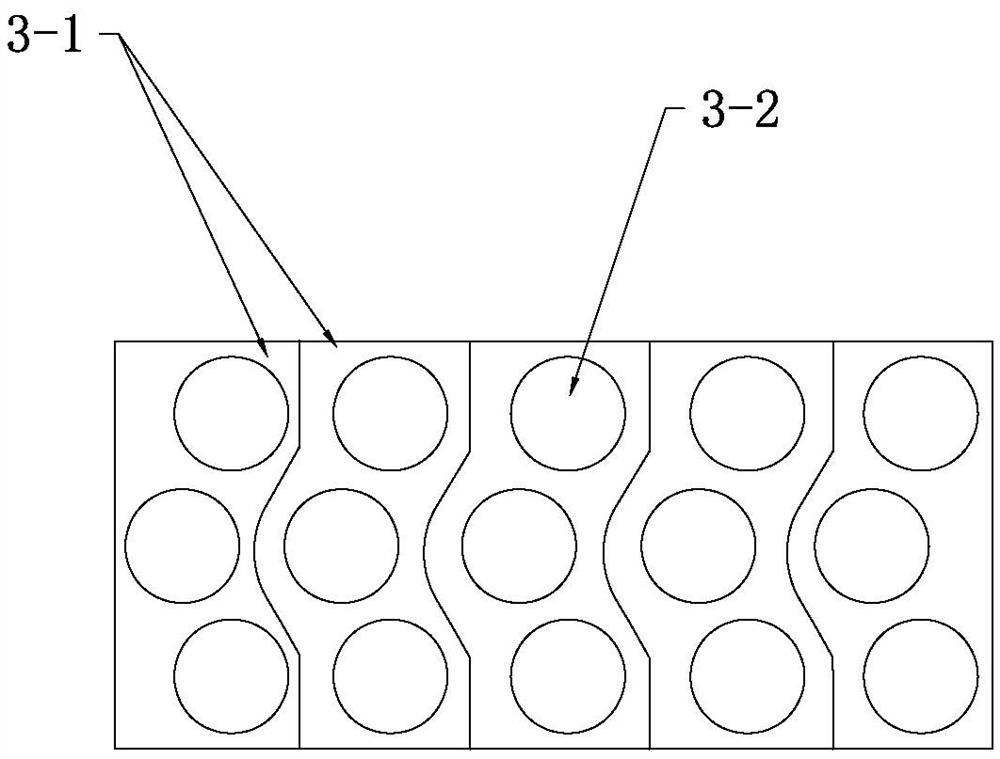

[0063] A plurality of material receiving brackets 3-1 of each stacking unit are arranged side by side, and the upper part of the material receiving bracket 3-1 is provided with a plurality of material receiving ports 3-2 for stacking cup materials, and multiple material receiving brackets The frame 3-1 can be combined into a whole. In this embodiment, except for the material receiving bracket 3-1 on both sides...

Embodiment 2

[0070] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and the embodiment is that the telescopic driving device of the telescopic and alternate telescopic stacking and unloading device of the AB unit is a cylinder, and the telescopic rod of the cylinder is connected with the receiving bracket 3-1 on one side.

Embodiment 3

[0072] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. The difference from Embodiment 1 is that the first translation driving device 5 of this embodiment is an air cylinder, and the telescopic rod of the air cylinder drives the telescopic support 3-7 of the first material receiving unit to translate. The second translation drive device 6 is an air cylinder, and the telescopic rod of the air cylinder drives the translation support platform 8 to translate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com