Continuous pipe pasting device

A tube sticking and conveying device technology, applied in packaging, labeling machines, transportation and packaging, etc., can solve problems such as unusable cup shape, poor stability, and many operators, and achieve high fault tolerance, high-speed operation, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

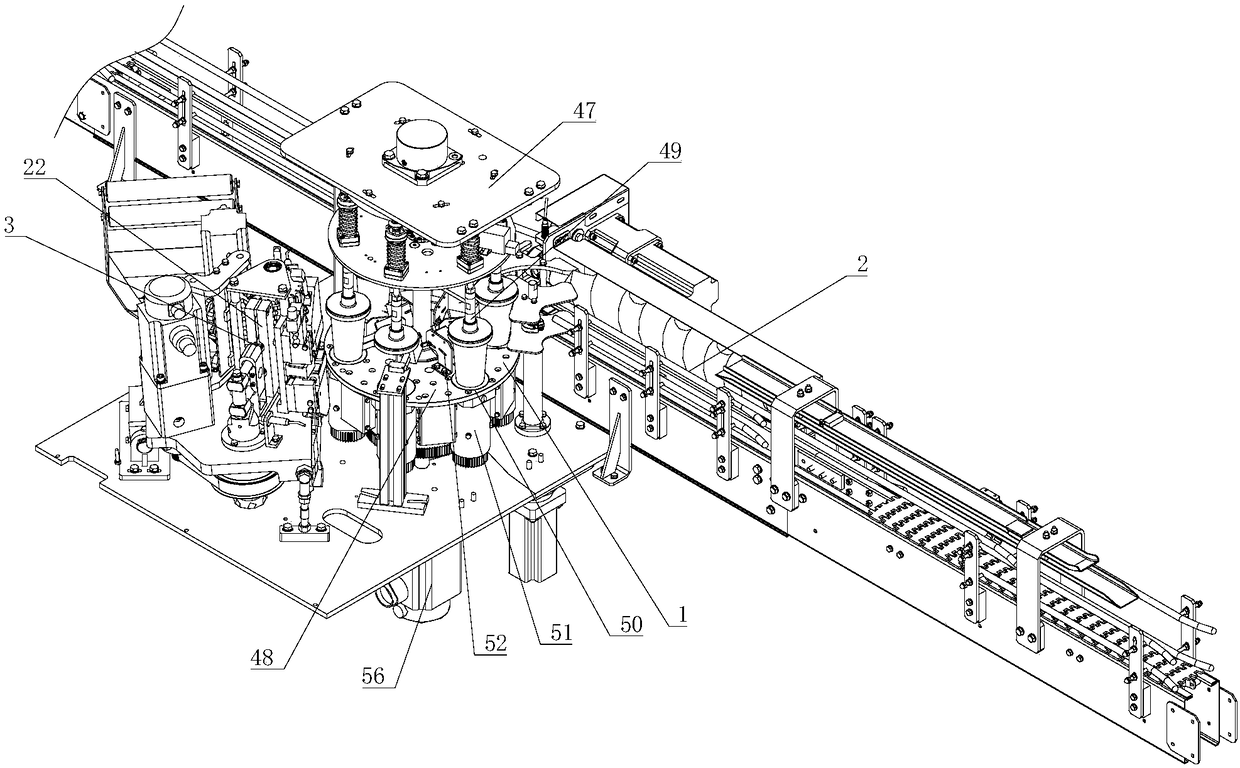

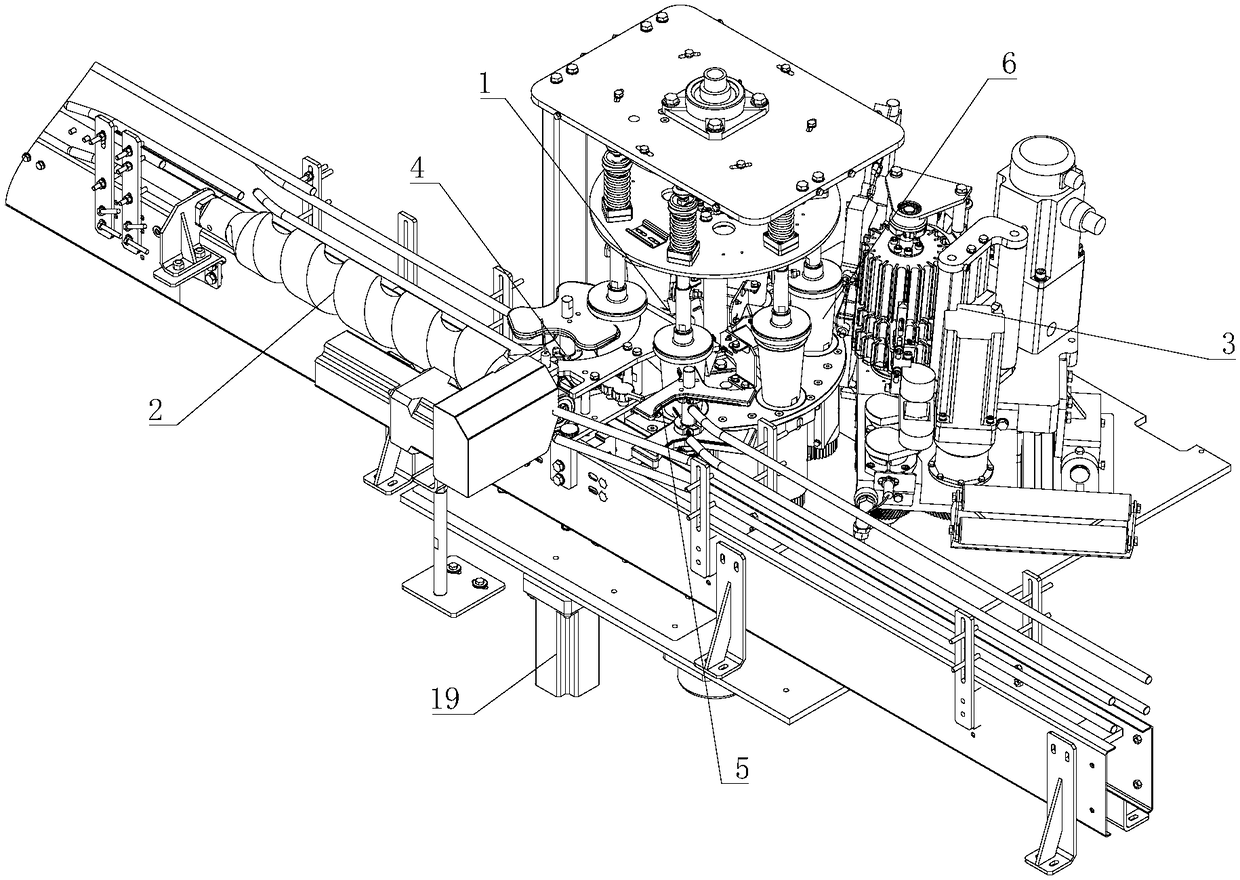

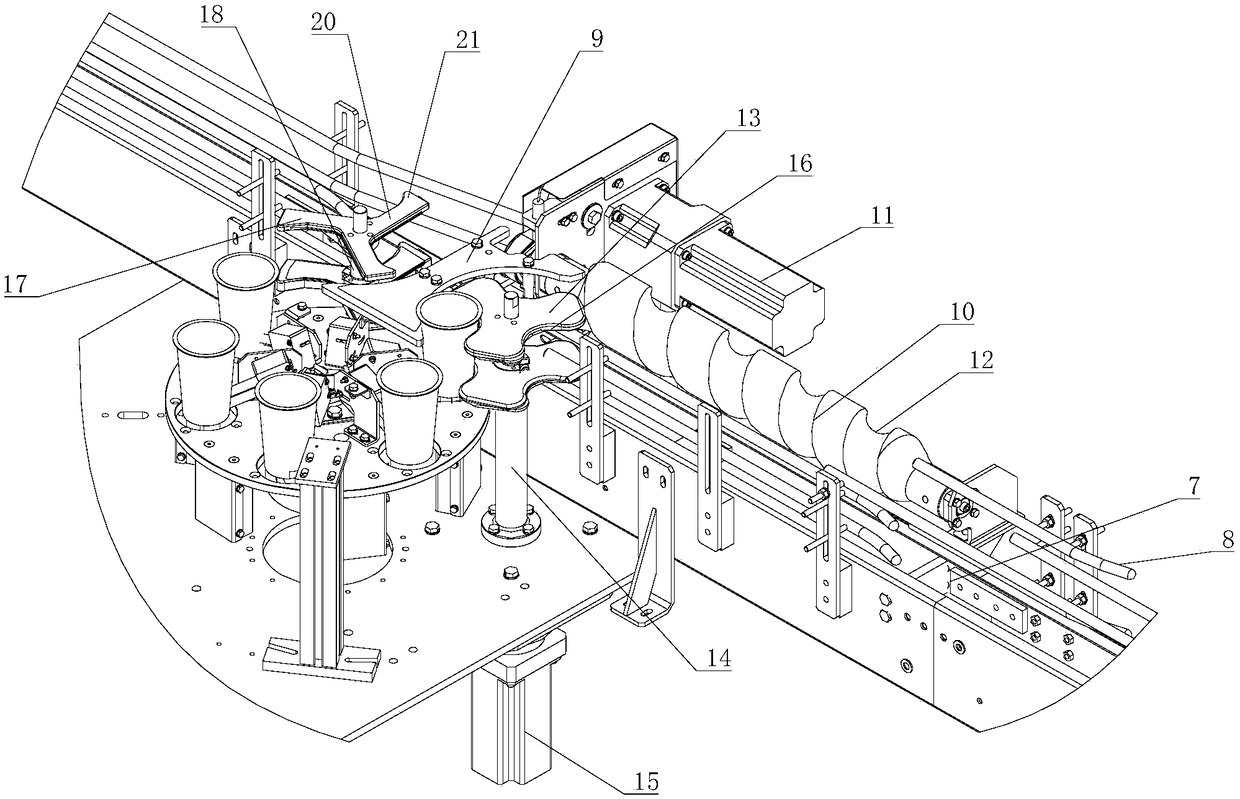

[0028] Such as figure 1 , figure 2As shown, a continuous tube sticking device includes a rotor cup device 1, a cup material conveying device 2, and a tube sticking device 3; the rotor cup device 1 is provided with an inlet 4, an outlet 5 and a plurality of surrounding To the set station 6, the station 6 revolves around the central axis, and the cup device 1 can drive the cup material positioned on the station 6 to perform autorotation and stop autorotation after turning to a specific position; The cup material conveying device 2 is arranged on one side of the feed port 4 and the discharge port 5 of the rotor device 1, and it is used to send the cup material to the station 6 of the rotor device 1 in sequence and The cup material after sticking the tube is sent out from the station 6; the tube sticking device 3 is arranged on the side of the rotor cup device 1 away from the feed port 4 and the discharge port 5, which is used to align the rotor cup device 1 After positioning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com