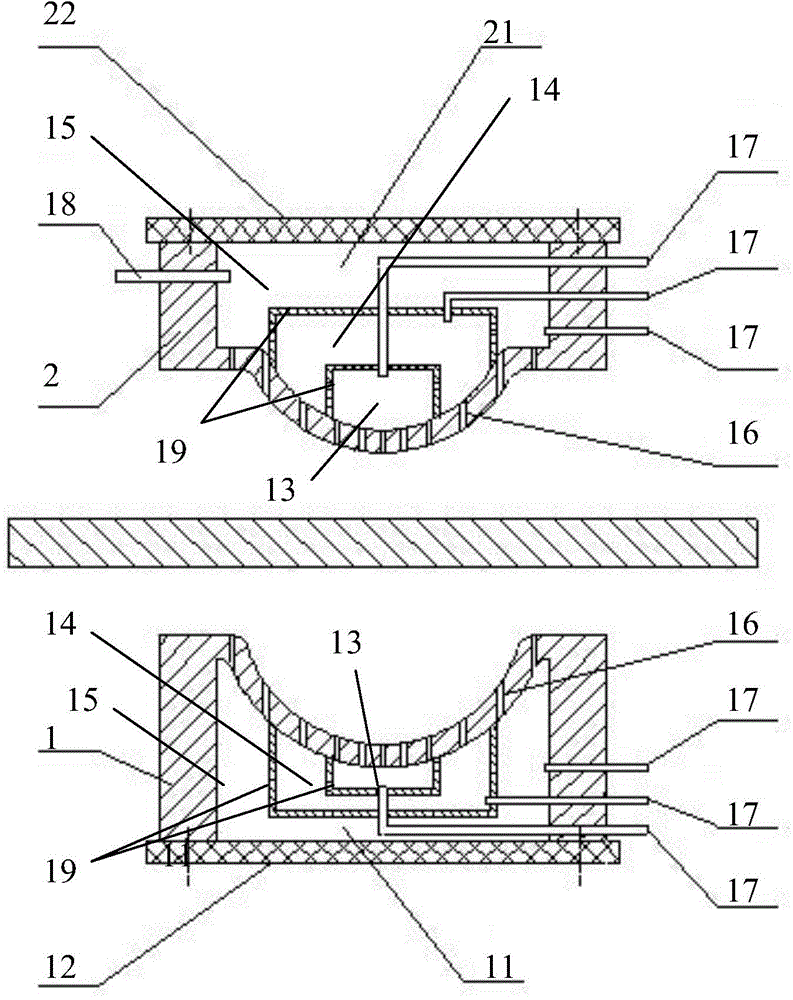

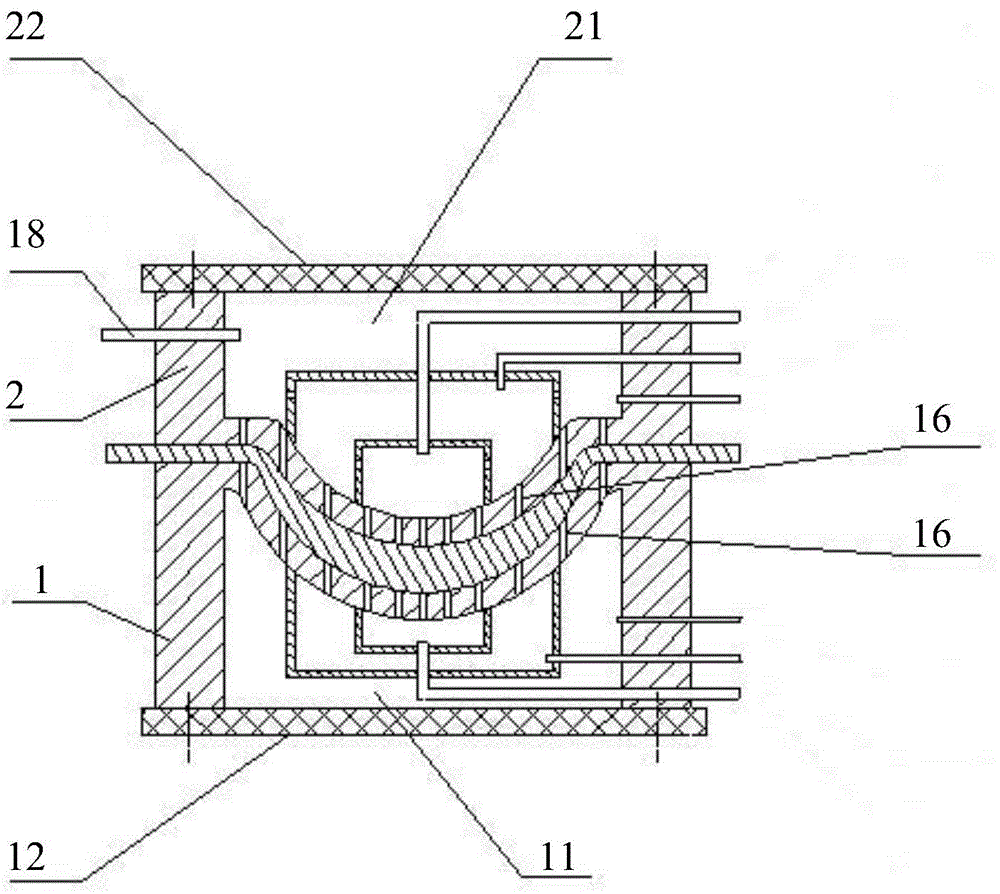

Underwear cup molding die and underwear molding method thereof

A molding die and molding method technology, which is applied to the field of molding dies for underwear cups, can solve the problems of unreasonable temperature distribution on the surface of the upper and lower dies, not easy to recover, and difficult to ensure molding temperature, etc. Reasonable and improve the effect of mold cup forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] When preheating the upper and lower molds of the traditional underwear cup hot molding machine, since the mold is a solid structure, it takes a long time to reach the predetermined temperature during preheating. At the same time, the upper and lower molds must be continuously powered on and heated during molding. Relatively high; and due to the irregular shape of the mold, the surface temperature distribution of the upper and lower molds is unreasonable, and it is difficult to ensure a suitable molding temperature.

[0035] Aiming at the deficiencies in the prior art, the present invention provides a molding mold for underwear cups. By setting up cavities in the upper and lower molds, and dividing the cavities into multiple areas for heat treatment at different temperatures, the mold can be molded in a short time. Complete preheating quickly within a short time, and keep the temperature distribution of the mold surface reasonable, reduce power consumption, save time, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com