Multifunctional automatic bagging device for cup, bowl and cover

A bagging device and multi-functional technology, which is applied in the field of multi-kinetic automatic bagging devices, can solve the problems that the lid packaging effect needs to be improved, and the structure of the automatic cup packaging machine is complex, etc., to reduce labor costs, high degree of automation, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

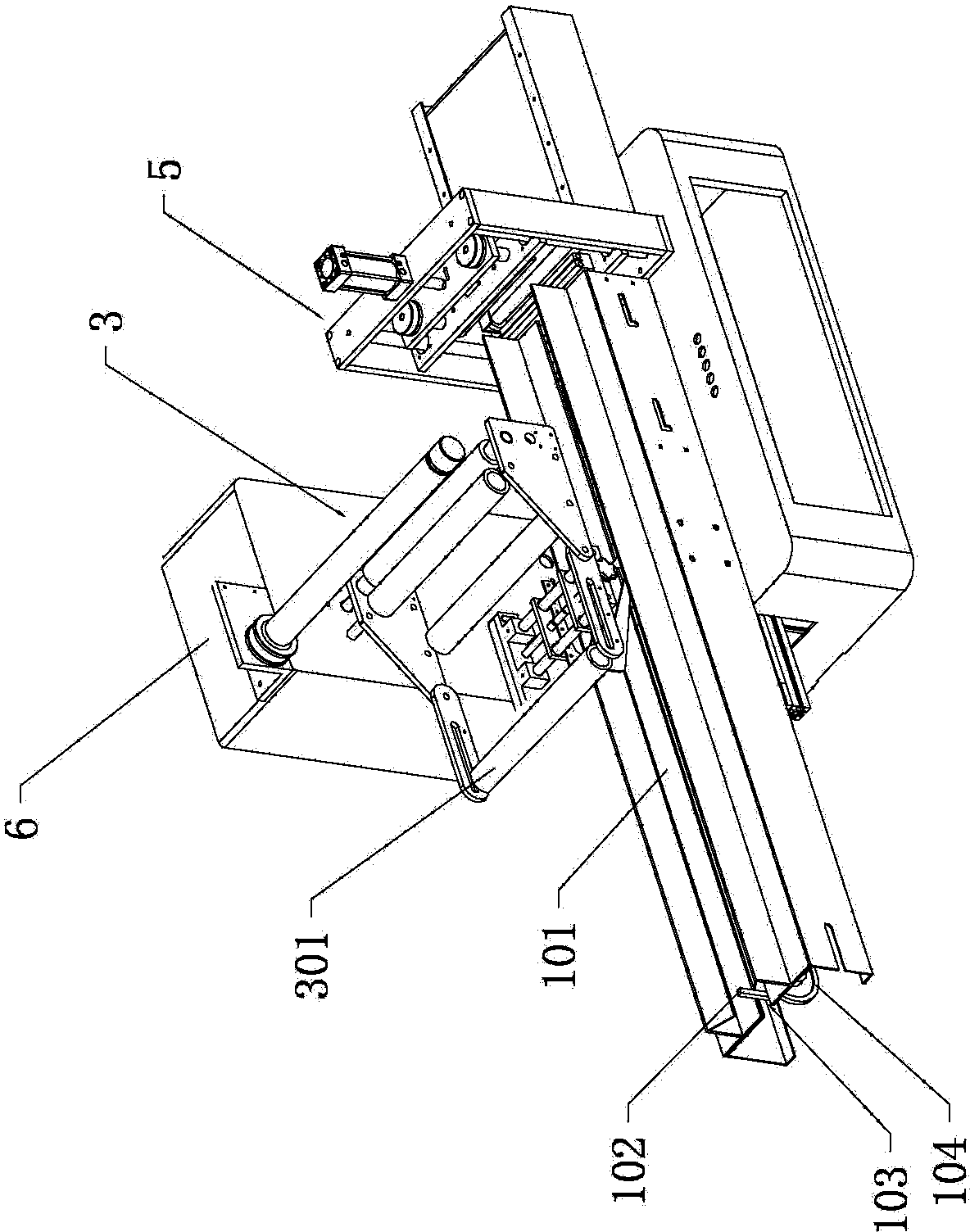

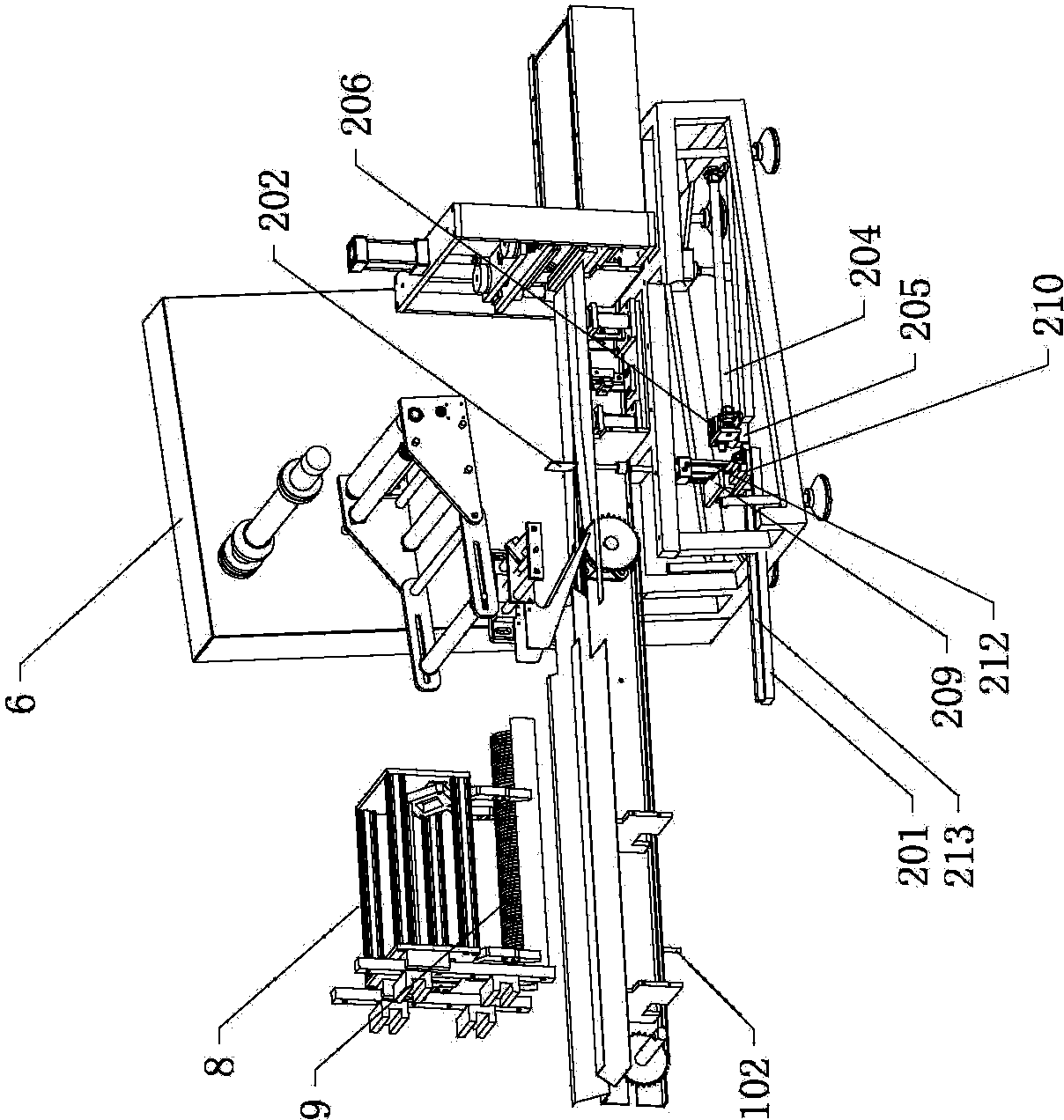

[0049] A multifunctional automatic bagging device for cups, bowls and lids, comprising a conveying unit, an abutting unit, a film support feeding unit 3, a bag making heat sealing unit and a controller.

[0050] see figure 1 The transmission unit includes a transmission drive device, a transmission chain 104, a transmission path 101, a sensor, and a push piece 102 for pushing the material 9, the sensor is arranged on the transmission path 101, and the transmission path 101 is provided with a limited transmission groove 103, so The conveying chain 104 is located below the limiting conveying groove 103 , the pushing piece 102 is mounted on the conveying chain 104 , and the pushing piece 102 circulates around the conveying channel 101 . The transmission path is arranged in an inverted trapezoidal shape, which is beneficial for the material 9 to fall into the long groove 103 provided in the length direction of the transmission path 101. The length direction of the long groove is p...

Embodiment 2

[0071] The main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference of this embodiment is that the middle seal transmission drive device and the transmission drive device are set as the same servo motor, and the servo motor is electrically connected to the controller. It should be noted that the middle seal transmission drive device and the transmission drive device can be servo motors In addition, it can also be an air cylinder, or the motor 105 of the transmission drive device of the transmission unit, and the motor 105 of the transmission drive device drives the transmission pressure wheel 401 and the transmission pulley 403 through the synchronous belt and the synchronous wheel. In order to make the moving speed of the conveying chain 104 of the conveying unit the same as the speed at which the film is driven by t...

Embodiment 3

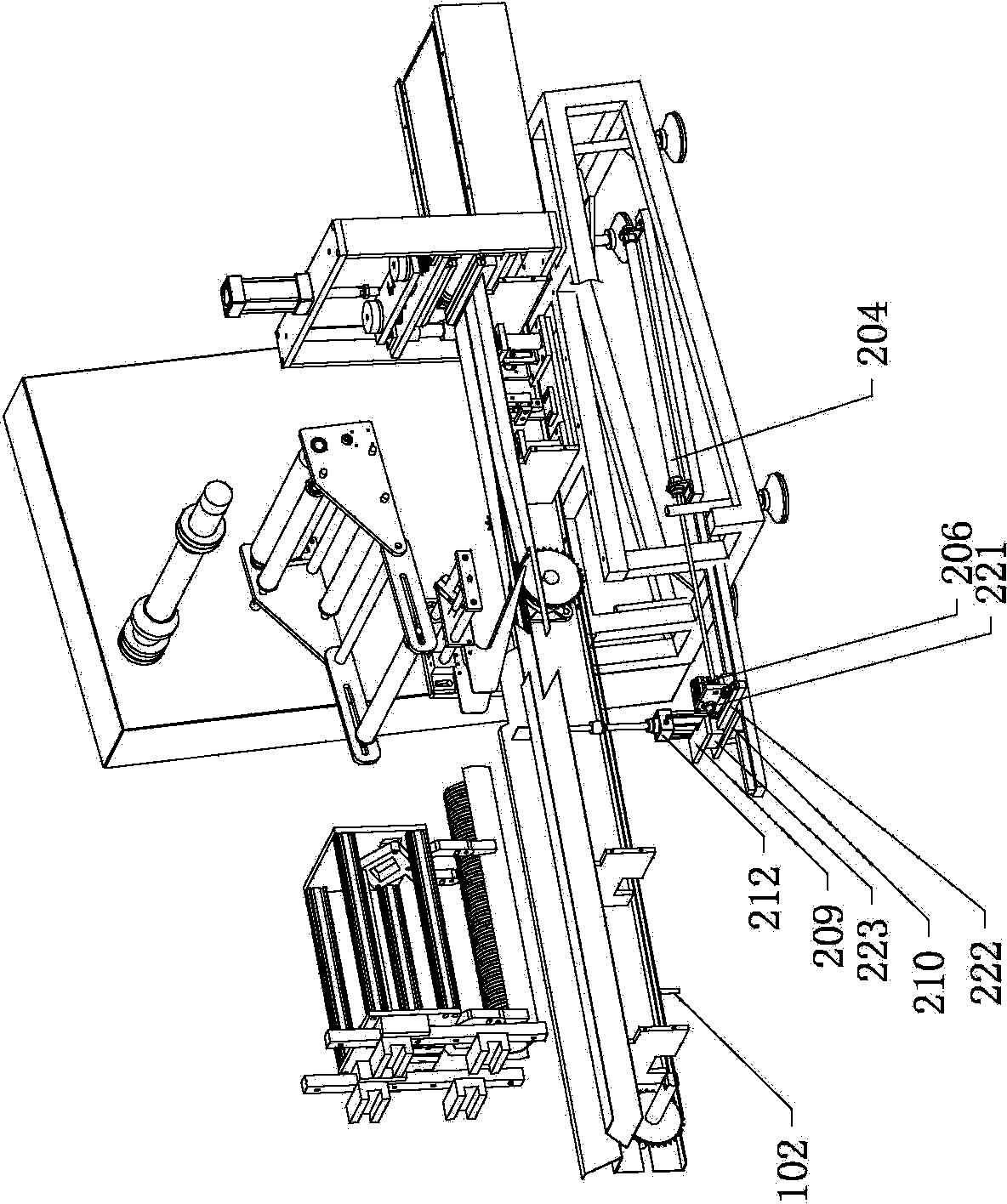

[0073] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. The difference between this embodiment and embodiment 1 is that, see Image 6 with Figure 7 , the abutment unit is provided with an abutment support frame 201, an abutment piece 202, an abutment piece forward pushing device, an abutment lifting device, a horizontal pushing device, a guide rail 213 (push guide piece) and a free slider 203 (sliding piece ). The abutting member 202 includes a connecting rod and an abutting plate, one end of the connecting rod is fixedly connected to the free slider 203, the other end of the connecting rod is fixedly connected to the abutting plate, and the free sliding block 203 is slidably sleeved on the guide rail 213 , the connecting rod is passed through the long slot 103 provided in the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com