Material pushing and stacking device

A push rod device and stacking technology, which is applied in the stacking, transportation, and packaging of objects, can solve the problems that automatic stacking cannot be realized, and cannot be directly applied, so as to save human resource costs, improve efficiency, and achieve stacking effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

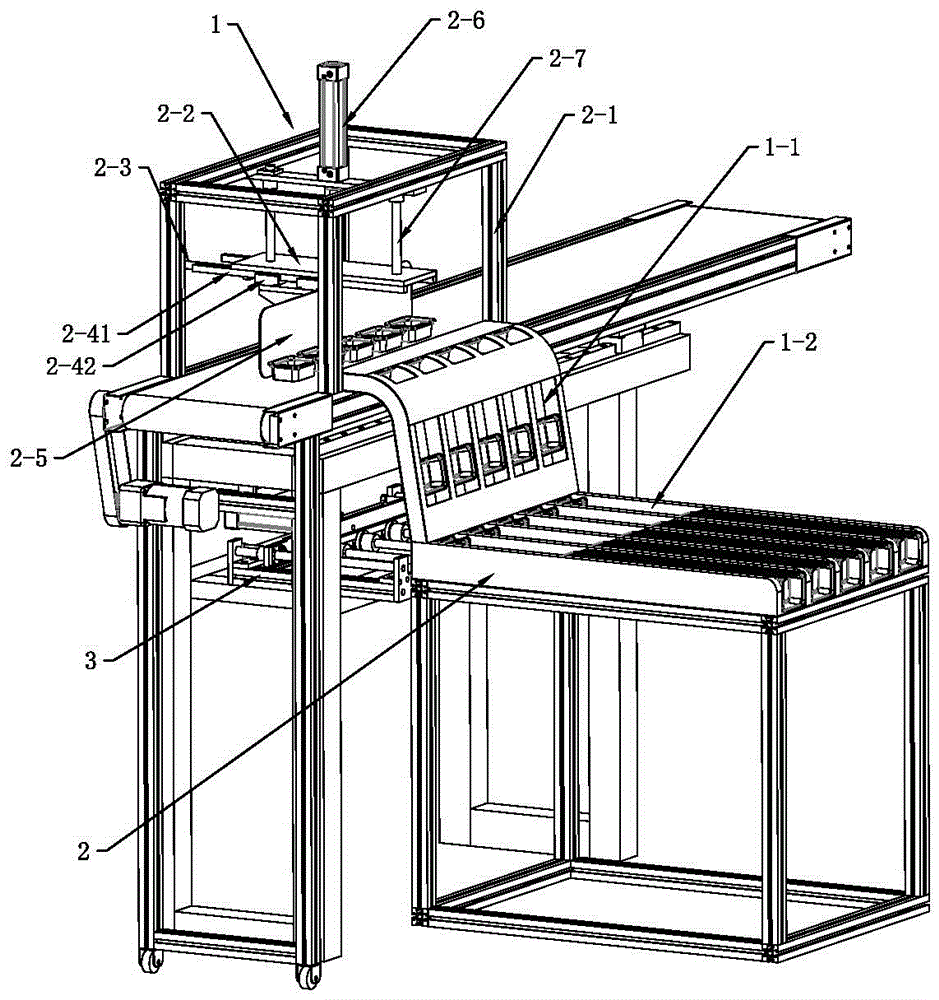

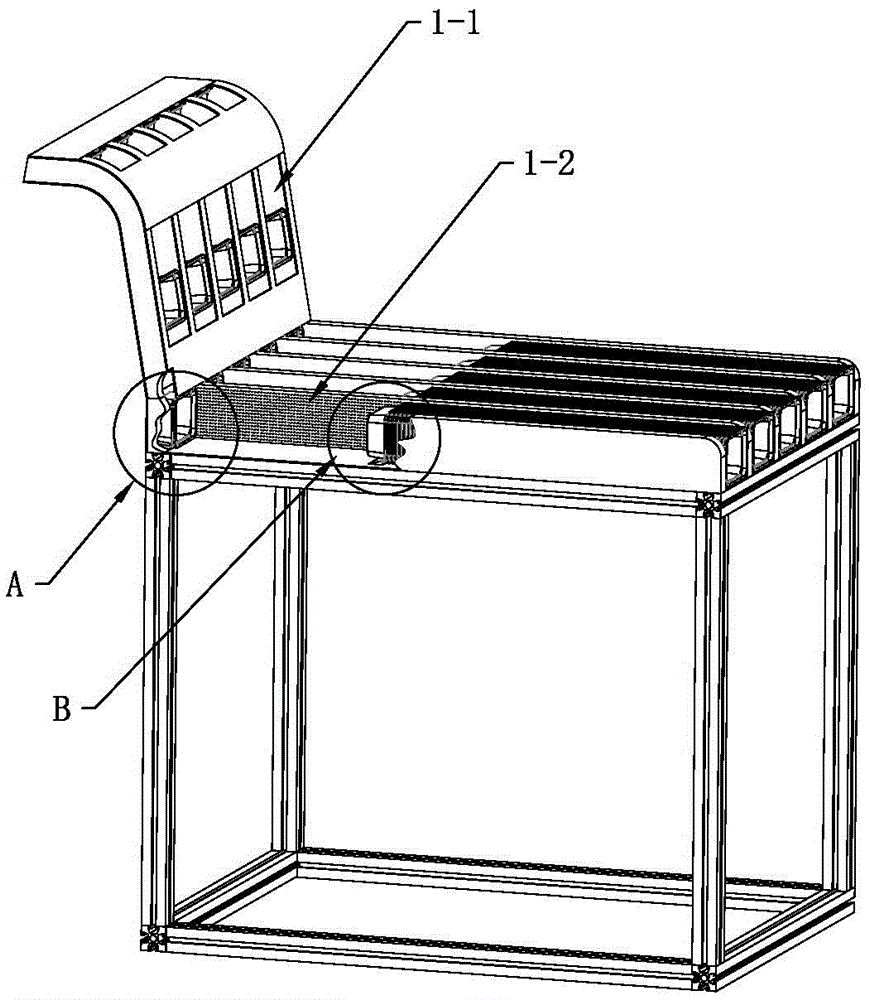

[0039] The pushing and stacking device of this embodiment includes a stacking device 2 , a pushing mechanism 1 and a pushing rod device 3 .

[0040] see figure 1 , push mechanism 1 includes support 2-1, lift cylinder 2-6, lift guide rod 2-7, connecting plate 2-2, push cylinder 2-3, guide rail and push plate 2-5, lift cylinder 2-6 and The lifting guide rod 2-7 is installed on the support 2-1, the connecting plate 2-2 is provided with a guide rod through hole, the lifting guide rod 2-7 passes through the guide rod through hole, and the lifting cylinder 2-6 drives the connecting plate 2-2 along the The lifting guide rod 2-7 moves up and down, and the push plate 2-5 is slidably installed on the connecting plate 2-2 by the guide rail. Block 2-42 is installed on push plate 2-5, pushes cylinder 2-3 and pushes plate 2-5 and drives to connect. In this embodiment, the pushing plate 2-5 includes two parts, one part is a flat plate for directly pushing the cup material, and the other pa...

Embodiment 2

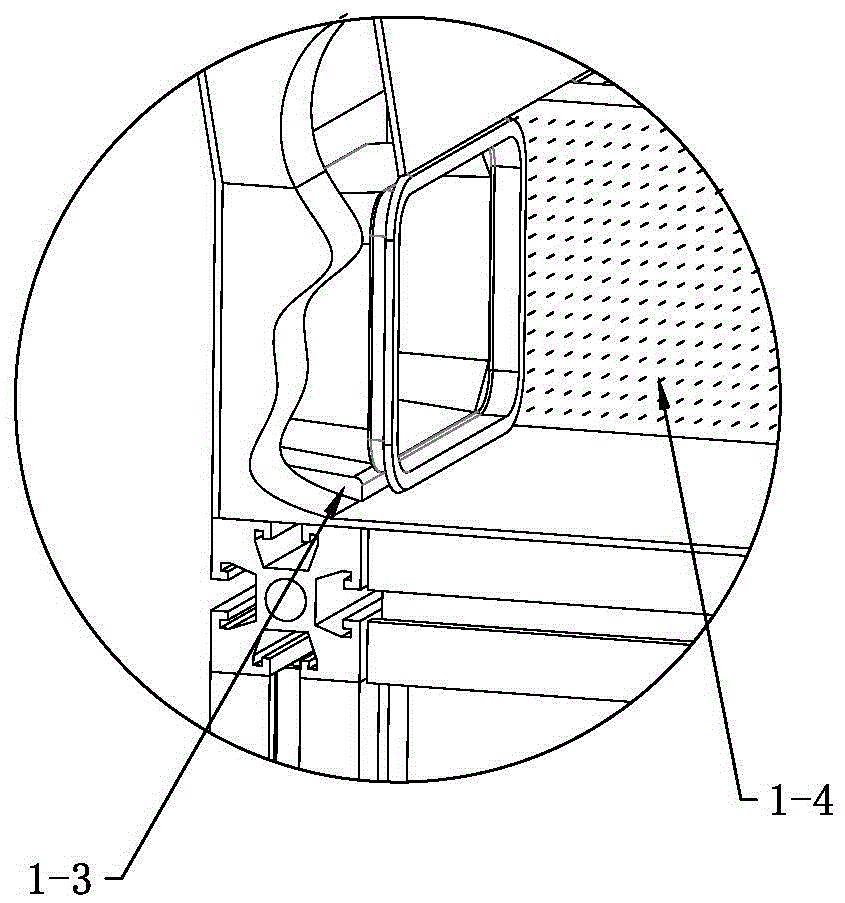

[0046] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the buffer structure 1-4 of the push-and-stack channel 1-2 is a multi-track deceleration belt, and the deceleration belt can also be used as a bearing bump 1-3.

Embodiment 3

[0048] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. see Image 6 , The push-and-stack channel 1-2 of this embodiment is provided with only one pad bump 1-3, and the pad bump 1-3 is located in the lower front of the blanking opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com