Preparation method of foam material for bra

A foam and bra technology, applied in the field of foam material preparation, can solve the problems of poor air permeability of PU foam material, unenvironmental production process, high open porosity, etc., achieves difficult growth and reproduction, good bacteriostatic effect, good Hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

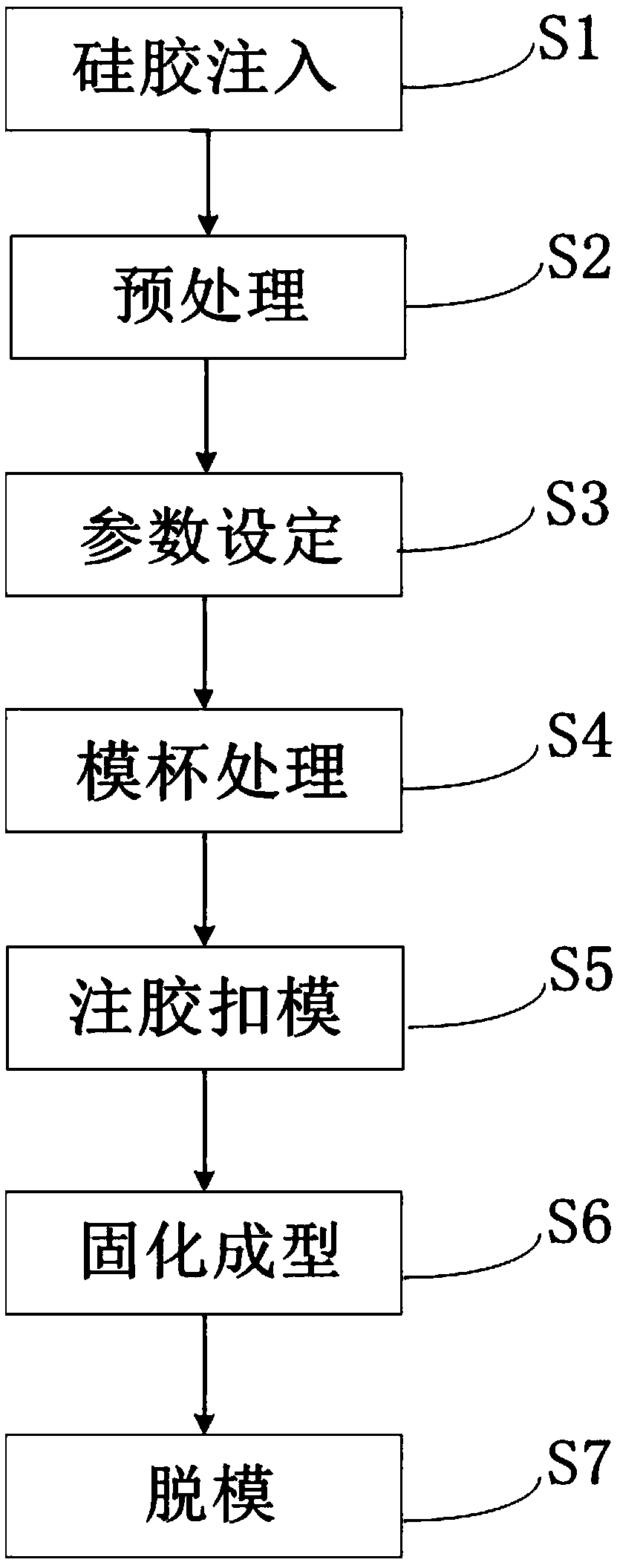

[0036] A kind of preparation method of the foam material that is used for bra of the present invention, as figure 1 shown, including the following steps:

[0037] S1. Silica gel injection: transport silicone gel A and silicone B containing foaming ingredients to channel A and channel B of the injection machine respectively;

[0038] S2. Pretreatment: keep the organic silica gel A and the organic silica gel B at a constant temperature to the working temperature required for silica gel pretreatment, and make preparations before injection;

[0039] S3. Parameter setting: set the injection parameters of the injection machine, and stir and mix the organic silica gel A and the organic silica gel B according to A:B=1:10~10:1 to obtain the silica gel mixture;

[0040] S4, mold cup treatment: carry out constant temperature pretreatment to the mold cup;

[0041] S5. Glue injection buckle mold: start the glue injection machine, inject the silica gel mixture into the concave mold of the...

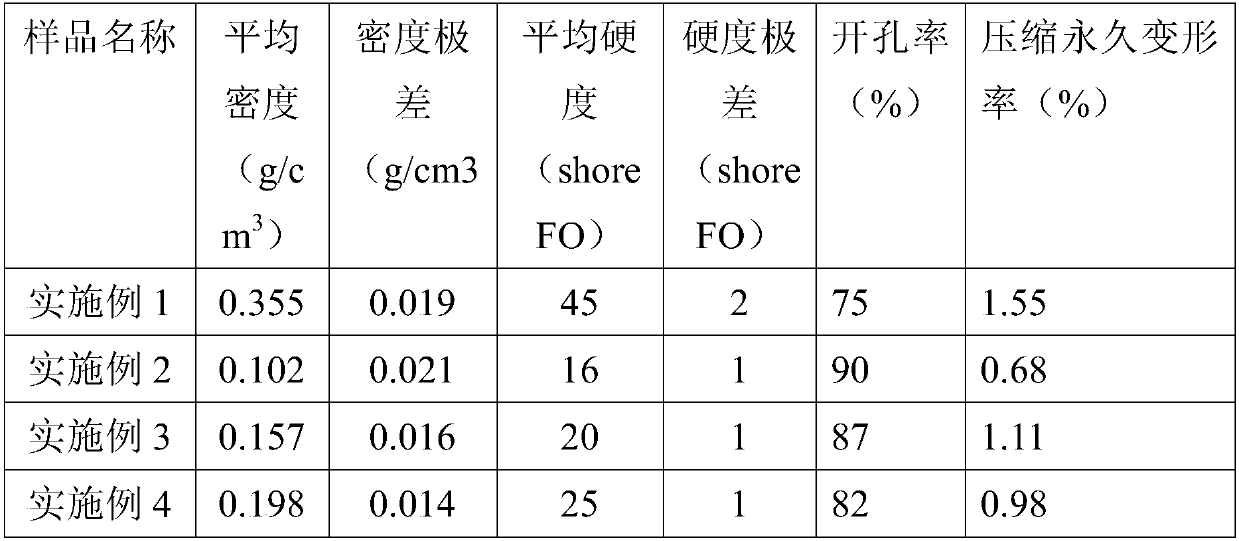

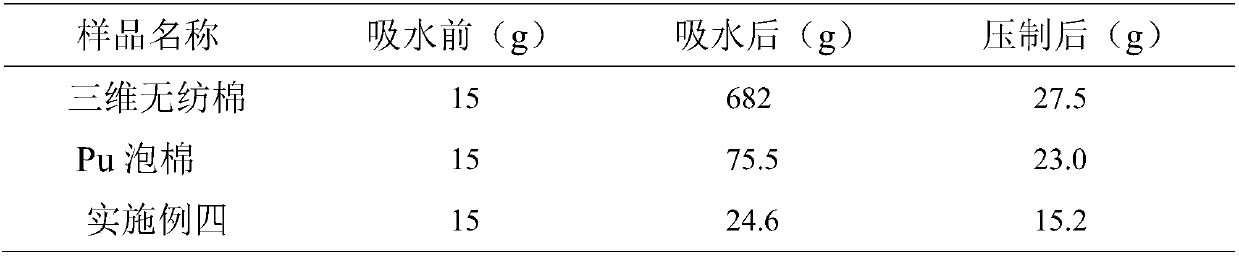

Embodiment 1

[0045] Embodiment 1, a kind of preparation method for the foam material of bra, wherein:

[0046] S1. Transport silicone gel A and silicone B containing foaming ingredients to channel A and channel B of the glue injection machine, respectively;

[0047] S2. Perform silica gel pretreatment on organic silica gel A and organic silica gel B at 25°C to prepare for injection;

[0048] S3. Set the glue injection parameters. The mixing ratio of silicone A and silicone B is A:B=1:5; the mixing speed is 4000rpm, the glue injection temperature is 45°C, and the glue output of the machine head is 12g / s.

[0049] S4, carry out constant temperature pretreatment to mold cup, pretreatment temperature is 35 ℃;

[0050] S5. Start the glue injection machine, inject 36g of uniformly mixed silica gel into the concave mold of the mold cup, fasten the punch, and lock the concave mold and the punch, and then turn the mold cup over , foaming at 50°C;

[0051] S6, curing after foaming for 60 minutes;...

Embodiment 2

[0053] Embodiment 2. A method for preparing a foam material for a bra, wherein:

[0054] S1. Transport silicone gel A and silicone B containing foaming ingredients to channel A and channel B of the glue injection machine, respectively;

[0055] S2. Perform silica gel pretreatment on organic silica gel A and organic silica gel B at 10°C to prepare for injection;

[0056] S3. Set the glue injection parameters, the mixing ratio of silicone A and silicone B is A:B=5:1, the mixing speed is 1000rpm, the glue injection temperature is 20°C, and the glue output of the machine head is 6g / s;

[0057] S4, carry out constant temperature pretreatment to mold cup, pretreatment temperature is 5 ℃;

[0058] S5, start the glue injection machine, inject 12g of uniformly mixed silica gel into the concave mold of the mold cup, buckle the punch, and lock the concave mold and the punch, and then turn the mold cup over , foaming at 20°C;

[0059] S6, curing after foaming for 10 minutes;

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com