Automatic powder weighing machine

A powder weighing and automatic technology, which is applied in the direction of weighing, weighing equipment and measuring devices for materials with special properties/forms, and can solve the problem of affecting the accuracy of powder output, frequent manual powder addition, and low weighing accuracy. problems, to achieve the effect of improving weighing accuracy, high degree of automation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

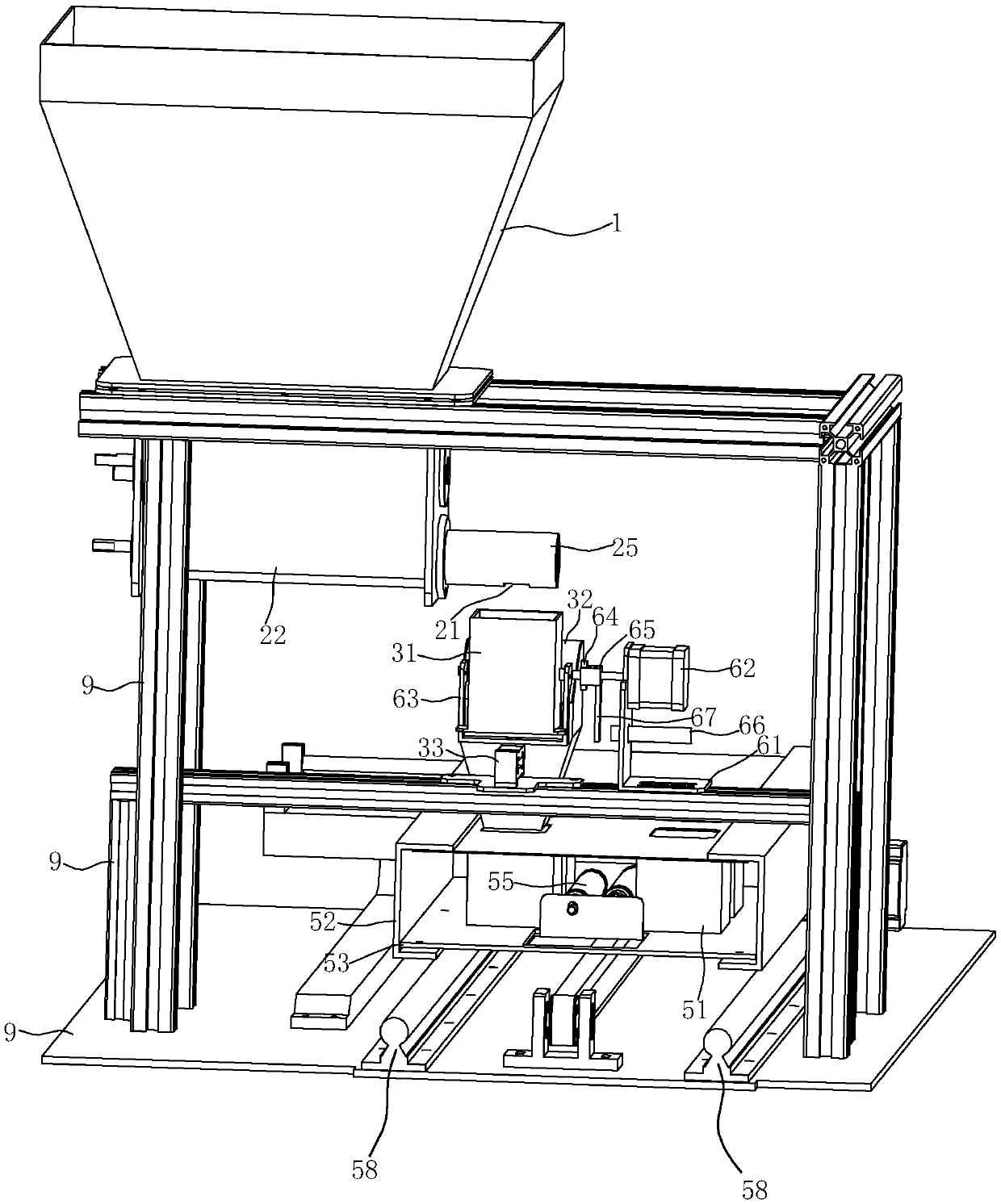

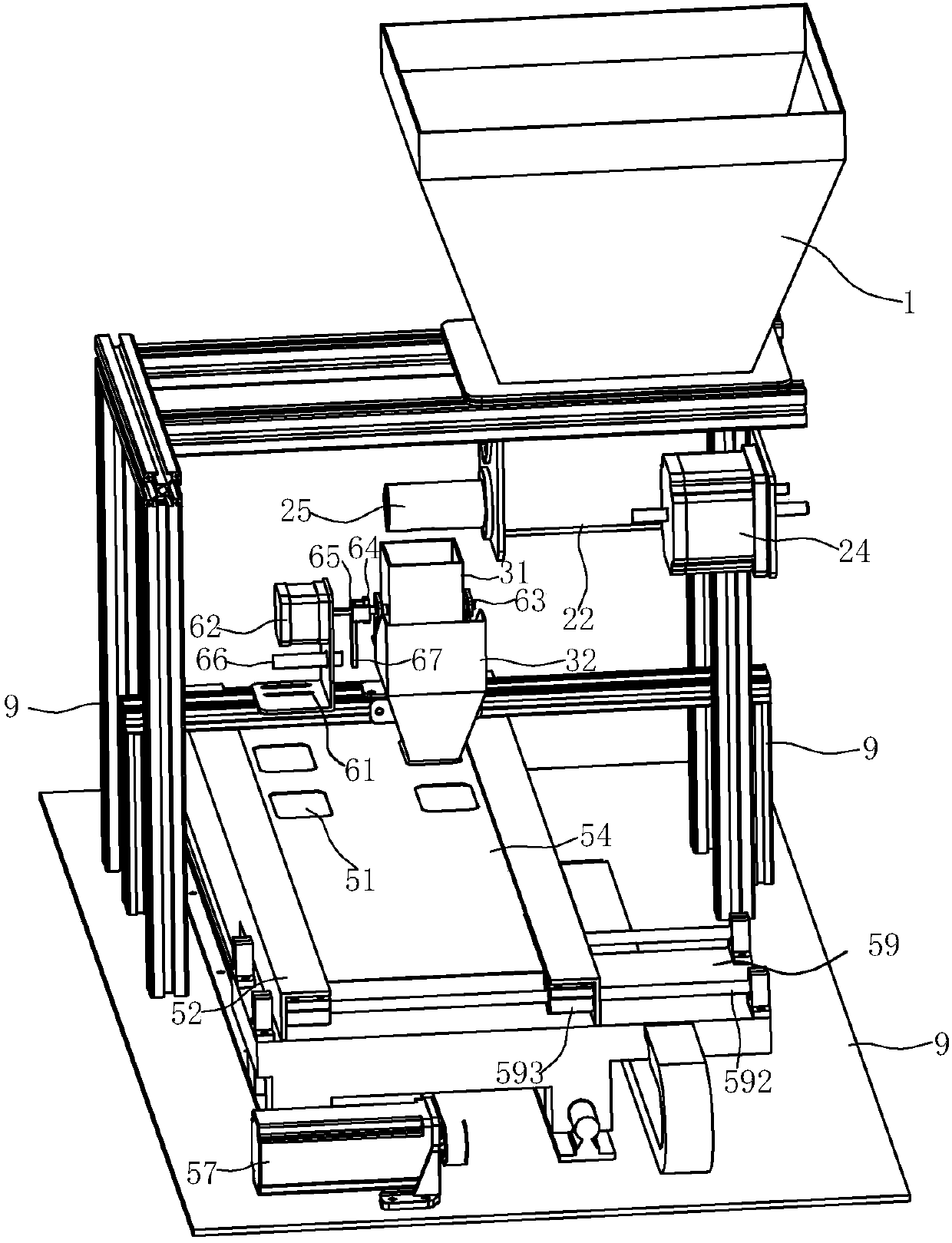

[0045] Such as Figure 1~4As shown, an automatic powder weighing machine includes a frame 9, a display device 7 arranged on the frame 9, a numerical control cabinet 8 arranged below the frame 9, and a machine set on the frame 9 from top to bottom Material storage barrel 1, feeding mechanism, weighing assembly, material bearing mechanism, frame 9 outer covers are provided with outer covers. The display device 7 is used to display the working parameters of the powder weighing machine. In the present embodiment, the display device 7 is a touch screen design; the storage tank 1 is used to hold the powder to be weighed; The powder is delivered to the weighing cup 31; the weighing assembly includes a weighing cup 31, a load cell 33 and a turning mechanism, and the load cell 33 is used for weighing the powder in the symmetrical cup 31; the display d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com