Improvements in investment casting

A technology of investment casting and wax mold, which is applied in the technical improvement field of investment casting, and can solve the problems such as high-standard finishing of casting parts that cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

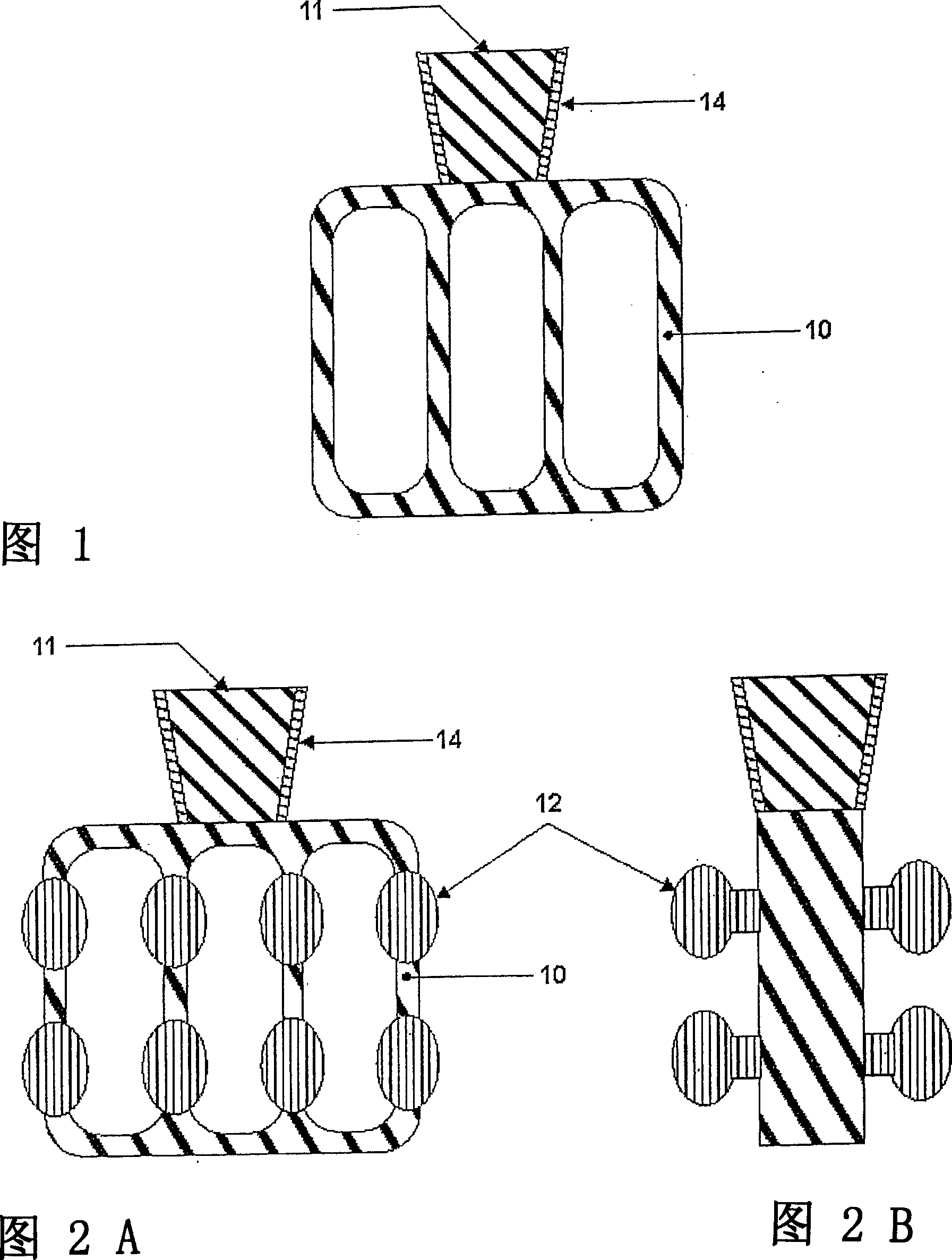

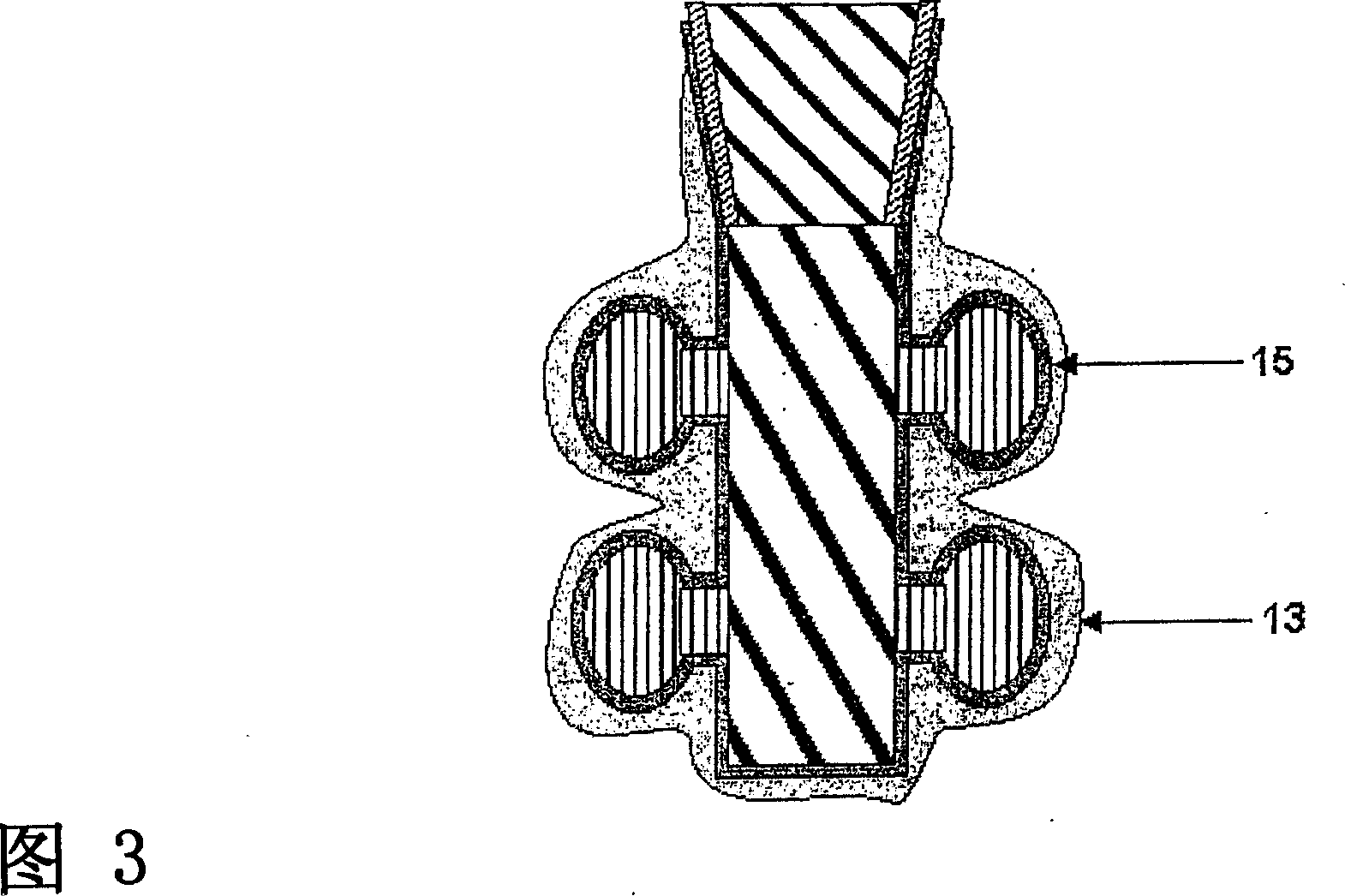

[0015] The figure shows a runner 10 with a pouring cup 14 filled with a wax pattern material 11 . A pattern 12 of the part to be molded is attached to the sprue by the treatment of wax, glue or a heat-sealing knife. It is known that the sprue 10, the pouring cup 11 and all the patterns 12 are formed of wax pattern material. However, according to the present invention, the sprue 10 has a higher percentage of microwave susceptor content than the original wax pattern 12 , and the pouring cup 11 has a higher content of microwave susceptor content than the sprue 10 . The mold 12 is formed from virgin wax, and the runner 10 and pouring cup 11 are formed from a recycled wax emulsion having a known fixed percentage of microwave susceptors.

[0016] In the first layer of sand grain coating outside the tree model, there is a certain proportion of microwave susceptors, which can be water, carbon, graphite or their related mixtures, and can also be other suitable susceptible substances. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com