Hot melt adhesive net diamond die cup and manufacturing method therefor

A production method and hot-melt adhesive technology, applied in clothing, underwear, baby underwear, etc., can solve the problems of not being able to use smooth bra mold cups, affecting the wearing effect of clothing, and easily scratching the outer layer of clothing, so as to improve the hand feel and Wearing effect, suitable for mass production, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

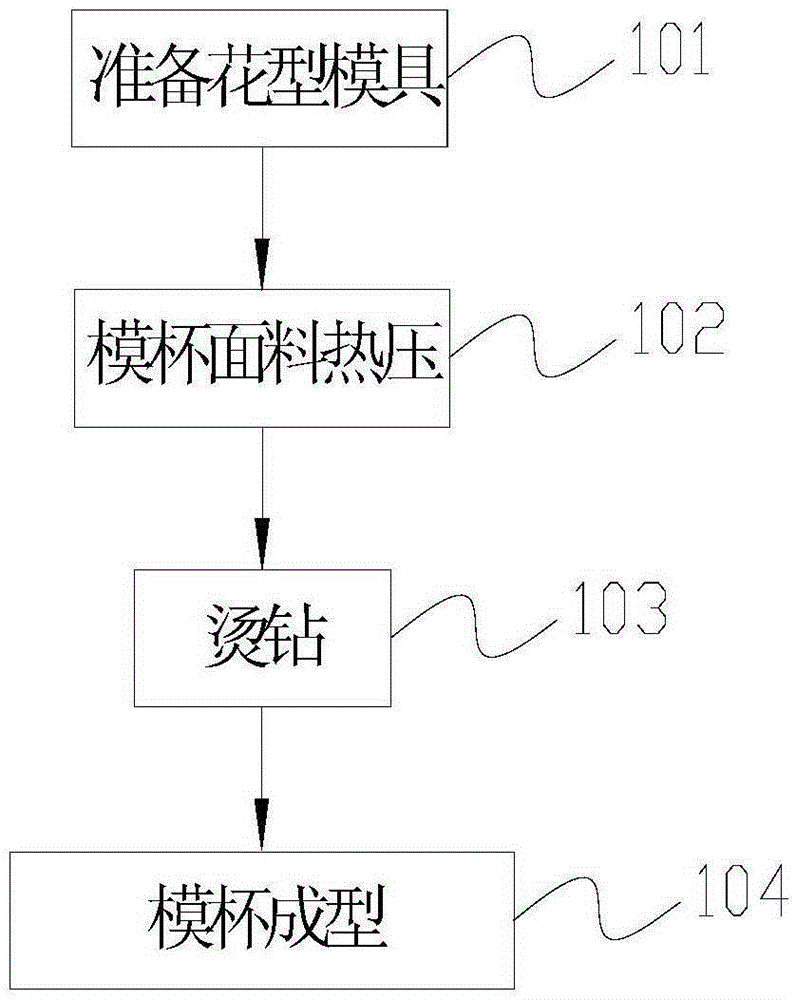

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

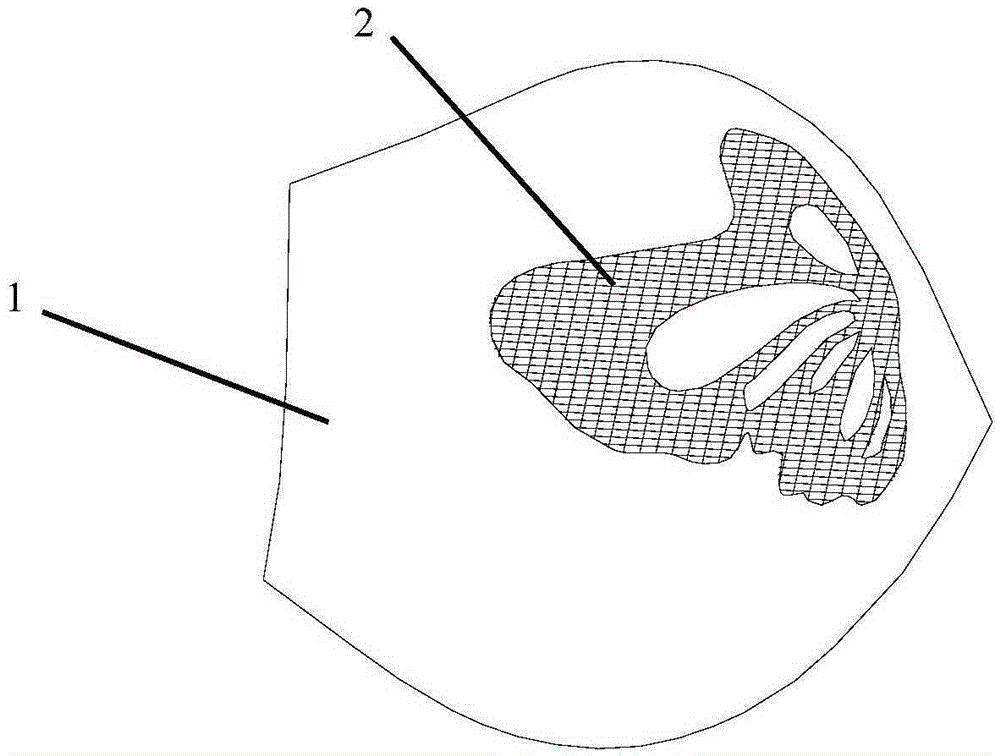

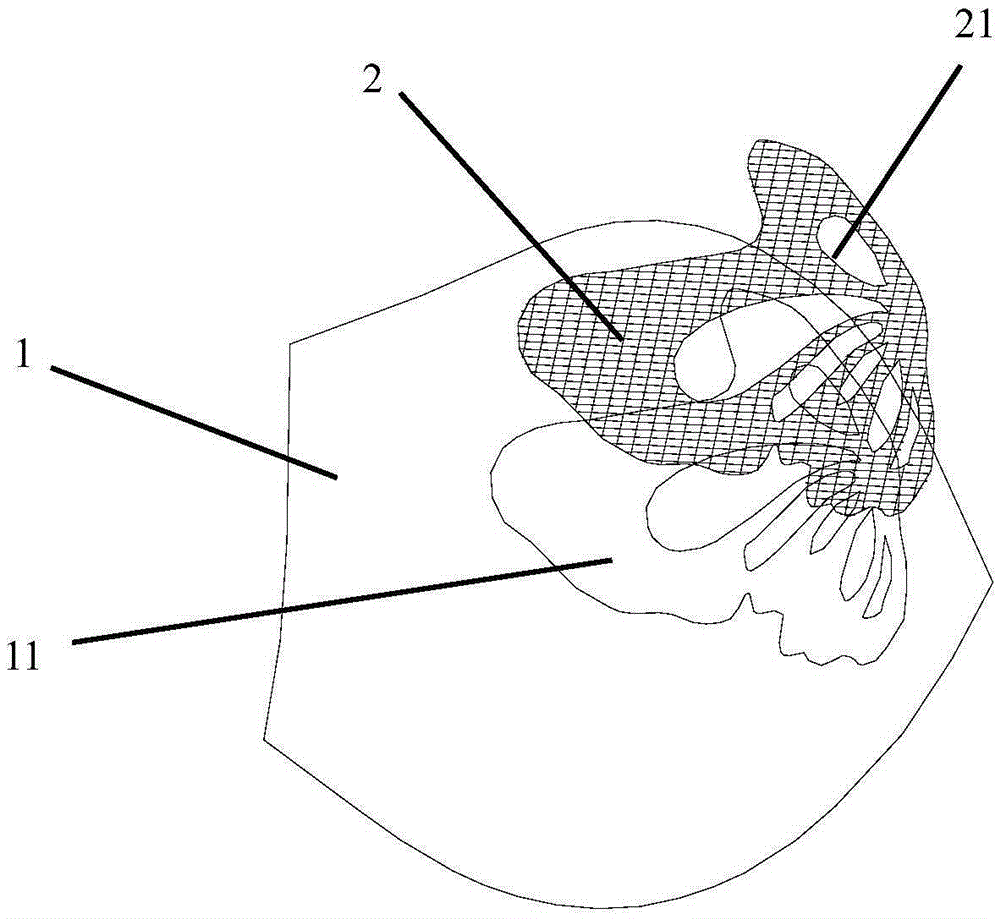

[0019] see figure 1 with 2 , a hot-melt adhesive mesh drill inlaid mold cup, comprising a mold cup body 1 and a sheet-shaped hot-melt glue mesh drill 2 fixed on the cup surface of the mold cup body 1, the cup surface of the mold cup body 1 is provided with The shape of the hot-melt adhesive mesh drill 2 is adapted to the pit 11, and the hot-melt adhesive mesh drill 2 is embedded in the pit 11. Wherein, the depth of the pit 11 is the same as the thickness of the hot melt adhesive mesh drill 2, and the surface of the hot melt adhesive mesh drill 2 is flush with the cup surface of the mold cup body 1. The dimple 2 only occupies a partial area of the cup surface of the mold cup body 1 . Hot-melt glue mesh drill 2 includes a sheet-shaped glue mesh and many rhinestones sprinkled on the surface of the glue mesh. The glue mesh at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com