Fiber filling paste and preparation method thereof

An optical fiber filling paste and formulation technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of oil separation or pulverization, high acid value of ointment, and high hydrogen evolution value, and achieve difficult oil separation, low hydrogen evolution value and low viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

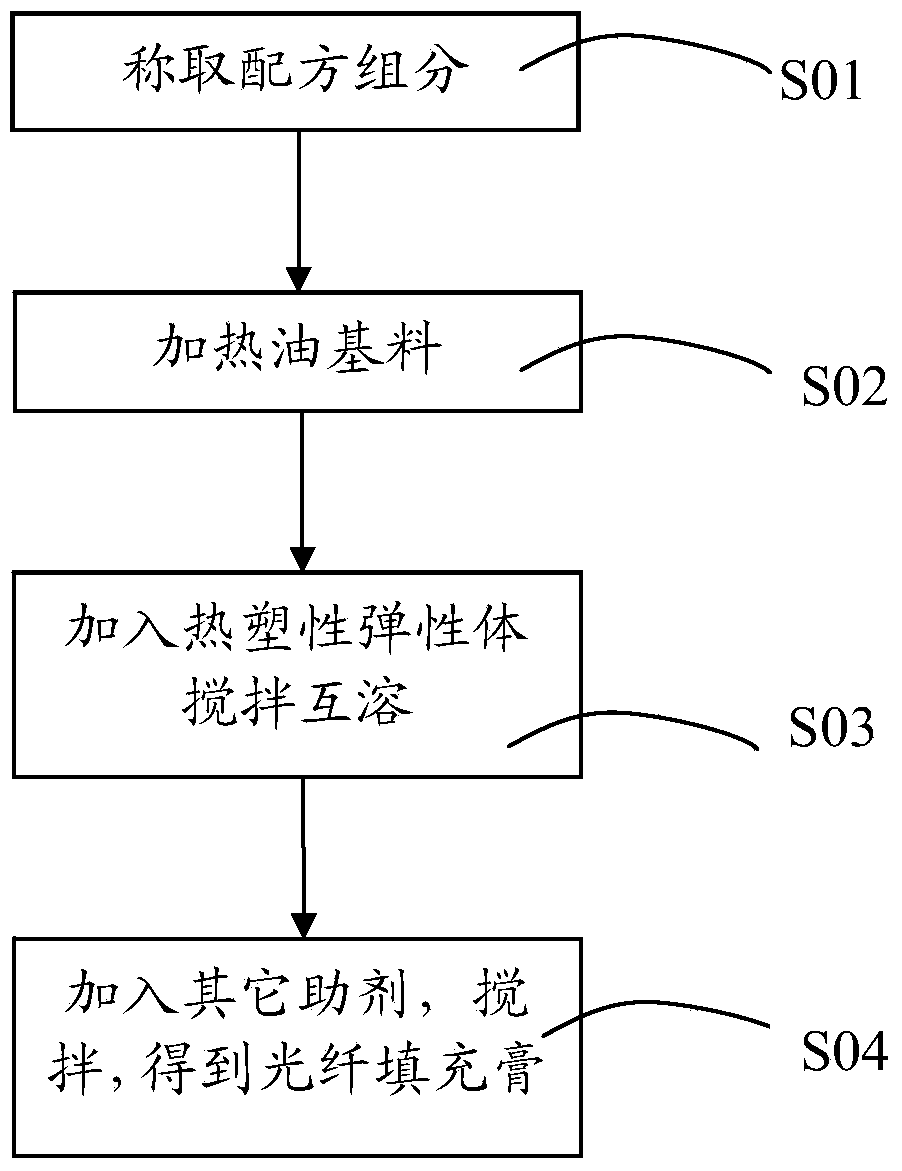

[0029] Correspondingly, the embodiment of the present invention provides the preparation method of the above optical fiber filling paste, the process flow chart of the method is as follows figure 1 shown, including the following steps:

[0030] S01, weigh the formula components: weigh each component according to the above optical fiber filling paste formula;

[0031] S02, heating oil base material;

[0032] S03, adding a thermoplastic elastomer to the oil-based material obtained in step S02, stirring and dissolving to obtain a mixed material 1;

[0033] S04, add other additives to the mixed material 1 obtained in step S03, and stir to obtain an optical fiber filling paste.

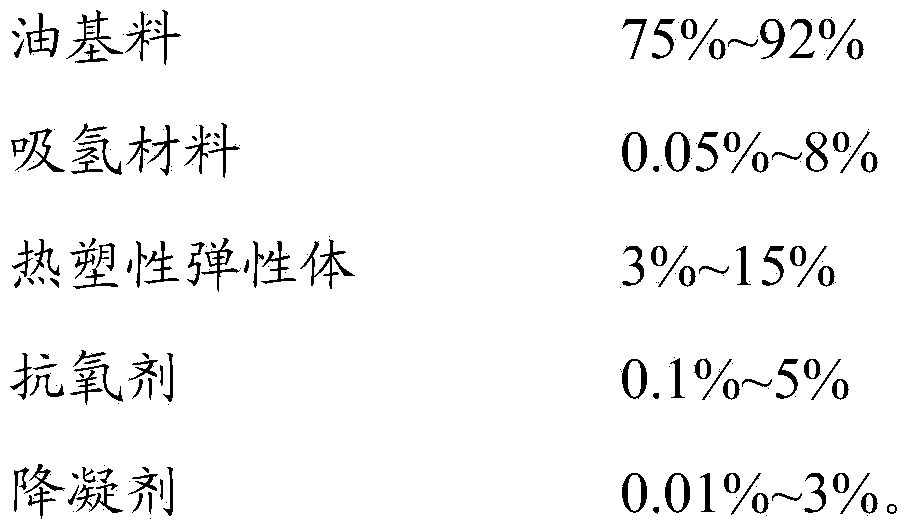

[0034] Specifically, in the above-mentioned step S01, the above-mentioned oil base material, hydrogen-absorbing material, thermoplastic elastomer, antioxidant, and pour point depressant are weighed in proportion with an electronic scale (with an accuracy of 1.0%), and the proportions thereof are as descr...

Embodiment 1

[0042] An optical fiber filling paste, comprising the following formula components by weight percentage:

[0043]

[0044] The preparation method of the optical fiber filling paste is as follows:

[0045] S11, weigh the formula components: weigh each component according to the above optical fiber filling paste formula;

[0046] S12, heating the oil base material; first heat the oil base material, heat up to 120°C while stirring, and continue stirring at this temperature for 1 hour, so that the oil base material is fully heated and evenly;

[0047] S13, forming a mixed material 1: adding the above-mentioned thermoplastic elastomer to the oil base material obtained in step S12, homogenizing and stirring for 1 hour, so that the thermoplastic elastomer and the oil base material are mutually soluble, and obtaining a mixed material 1;

[0048] S14, optical fiber filling paste: first add the above-mentioned antioxidant and pour point depressant to the mixed material 1 obtained in...

Embodiment 2

[0057] An optical fiber filling paste, comprising the following formula components by weight percentage:

[0058]

[0059] The preparation method of the optical fiber filling paste is as follows:

[0060] S21, weighing the formula components: weighing each component according to the above optical fiber filling paste formula;

[0061] S22, heating the oil base material; first heat the oil base material, heat up to 120°C while stirring, and continue stirring at this temperature for 0.5 hours, so that the oil base material is fully heated and evenly;

[0062] S23, forming a mixed material 1: adding the above-mentioned thermoplastic elastomer to the oil base material obtained in step S22, homogenizing and stirring for 1 hour, so that the thermoplastic elastomer and the oil base material are mutually soluble, and obtaining a mixed material 1;

[0063] S24, optical fiber filling paste: first add the above-mentioned antioxidant and pour point depressant to the mixed material 1 ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com