Hard high-damping foamed rubber sole and preparation method thereof

A foam rubber and hard technology, applied in the field of hard high shock-absorbing foam rubber soles and its preparation, can solve the problems of weak shock-absorbing effect, short service life, poor elasticity, etc., and achieve good anti-aging performance and high density Low, obvious effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

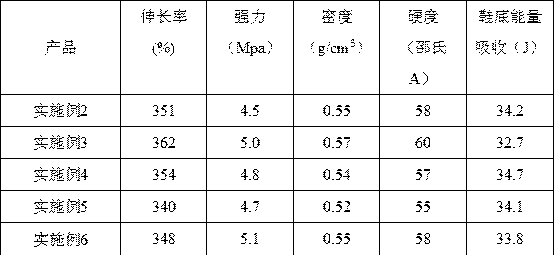

Examples

Embodiment 1

[0020] A hard and highly shock-absorbing foamed rubber sole, made of the following raw materials in parts by weight: 60-90 parts of natural rubber, 10-40 parts of neoprene rubber, 3-7 parts of active zinc oxide, and 1-3 parts of magnesium oxide , 1-3 parts of stearic acid, 0.5-1 parts of anti-aging agent I, 1-2 parts of anti-aging agent II, 5-8 parts of terpene resin, 6-15 parts of black ointment, 15-25 parts of naphthenic oil, charcoal Black 20-40 parts, urea 1-3 parts, foaming agent Ⅰ 1-3 parts, foaming agent Ⅱ 1-3 parts, physical foaming agent 3-5 parts, accelerator Ⅰ 1-2 parts, accelerator Ⅱ 0.1- 0.5 parts, sulfur 1-3 parts.

[0021] Preferably, it is made of the following raw materials in parts by weight: 80 parts of natural rubber, 20 parts of neoprene rubber, 5 parts of active zinc oxide, 1 part of magnesium oxide, 2 parts of stearic acid, 1 part of anti-aging agent I, 1.5 parts of anti-aging agent II 5 parts of terpene resin, 10 parts of black ointment, 20 parts of na...

Embodiment 2

[0035] A hard and highly shock-absorbing foamed rubber sole, made of the following raw materials in parts by weight: 80 parts of natural rubber, 20 parts of neoprene rubber, 5 parts of active zinc oxide, 1 part of magnesium oxide, 2 parts of stearic acid, anti-aging 1 part of agent I, 1.5 parts of anti-aging agent II, 5 parts of terpene resin, 10 parts of black ointment, 20 parts of naphthenic oil, 25 parts of carbon black, 1 part of urea, 2 parts of foaming agent I, and 1 part of foaming agent II , 3 parts of physical foaming agent, 1 part of accelerator I, 0.4 parts of accelerator II, and 1.2 parts of sulfur.

[0036] The anti-aging agent I is anti-aging agent MB, and the anti-aging agent II is anti-aging agent 4010NA.

[0037] The foaming agent I is the foaming agent AC, and the foaming agent II is the foaming agent OBSH.

[0038] The accelerator I is accelerator DM, and the accelerator II is accelerator TMTD. The physical foaming agent is a microsphere foaming agent.

...

Embodiment 3

[0045] A hard and highly shock-absorbing foamed rubber sole, made of the following raw materials in parts by weight: 85 parts of natural rubber, 15 parts of neoprene, 3 parts of active zinc oxide, 2 parts of magnesium oxide, 1.7 parts of stearic acid, anti-aging 0.7 parts of agent I, 1.5 parts of anti-aging agent II, 7 parts of terpene resin, 8 parts of black ointment, 17 parts of naphthenic oil, 30 parts of carbon black, 1.5 parts of urea, 1 part of foaming agent I, and 2 parts of foaming agent II , 5 parts of physical foaming agent, 2 parts of accelerator I, 0.1 part of accelerator II, and 1.5 parts of sulfur.

[0046] The anti-aging agent I is anti-aging agent MB, and the anti-aging agent II is anti-aging agent 4010NA.

[0047] The foaming agent I is the foaming agent AC, and the foaming agent II is the foaming agent OBSH.

[0048] The accelerator I is accelerator DM, and the accelerator II is accelerator TMTD. The physical foaming agent is a microsphere foaming agent.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com