Torsion resistant photoelectric composite medium-voltage drum cable

A photoelectric composite, torsion-resistant technology, applied in power cables, insulated cables, power cables with shielding/conducting layers, etc. Low temperature resistance, poor aging resistance and other problems, to achieve the effect of improving various properties and service life, improving performance and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

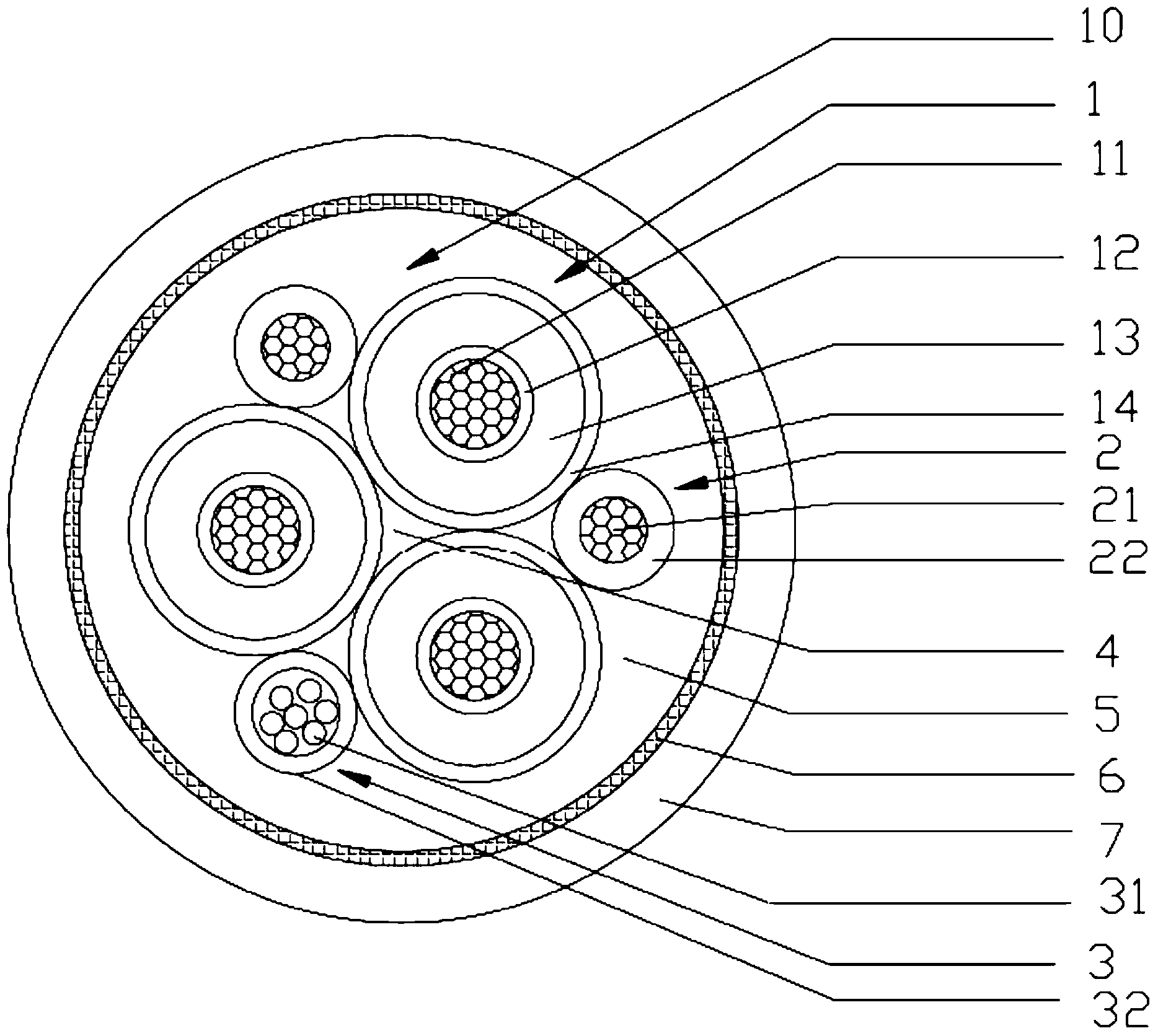

[0013] Example: see figure 1 As shown, a torsion-resistant photoelectric composite medium-voltage reel cable, including three power cores 1 and two ground cores 2 twisted together to form a cable core 10, and an optical unit 3, coated on the cable core 10 The outer special neoprene inner sheath 5, the reinforcement layer 6 woven on the outside of the special neoprene inner sheath 5 and embedded in it, the special neoprene outer sheath 7 wrapped outside the reinforcement layer 6, the reinforcement layer 6 is formed by braiding high-strength polyester filaments. In the cable core 10, three power cores 1 are closely arranged along the circumferential direction, and the central gap between the three power cores 1 is filled with semi-conductive fillers 4, semi-conductive fillers Conductive filler 4 is made of semi-conductive rubber, two ground wire cores 2 and a light unit 3 are scattered and arranged between the outer sides of two adjacent power wire cores 1 along the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com