Device for brown rice deinsectization enzyme

An insect-killing enzyme and brown rice technology, which is applied in heating preservation of seeds and chemical preservation of seeds, etc., can solve the problem of high cracking rate of brown rice, and achieve low bursting rate, small bursting rate, and less loss of nutrients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

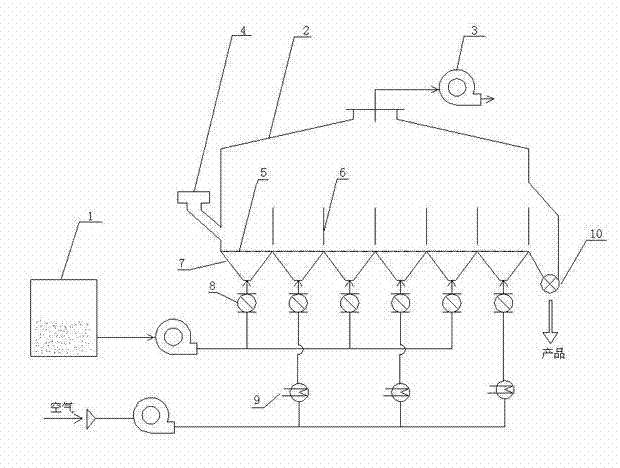

[0017] A brown rice disinfestation enzyme device, comprising a processing bin 2, a feed port 4 on the processing bin 2, and a discharge port 10 on the side corresponding to the feed port on the processing bin, and a transmission device located below the feeding port 4 in the processing bin 2 Belt 5, the material falls from the feed port and is sent to the discharge port through the conveyor belt. Ventilation holes are distributed on the conveyor belt. There are multiple air inlets 7 closely arranged along the conveying direction of the conveyor belt below the conveyor belt. Superheated steam generator The superheated steam generated by 1 and the hot air generated by the air heater 9 are sent to each air inlet 7 through the air pump and the pipeline, and then go to the material through the vent hole, and then discharged from the air outlet. The superheated steam and hot air are passed into adjacent air inlets respectively. The gas permeating through the adjacent air inlets is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com