Hot air flow self-regulated type grain drying device

A technology of grain drying and hot air flow, which is applied in lighting and heating equipment, dry cargo handling, drying solid materials, etc., can solve the problem of high cracking rate of grain drying, and achieve the goal of reducing cracking rate, reducing flow rate without reducing heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

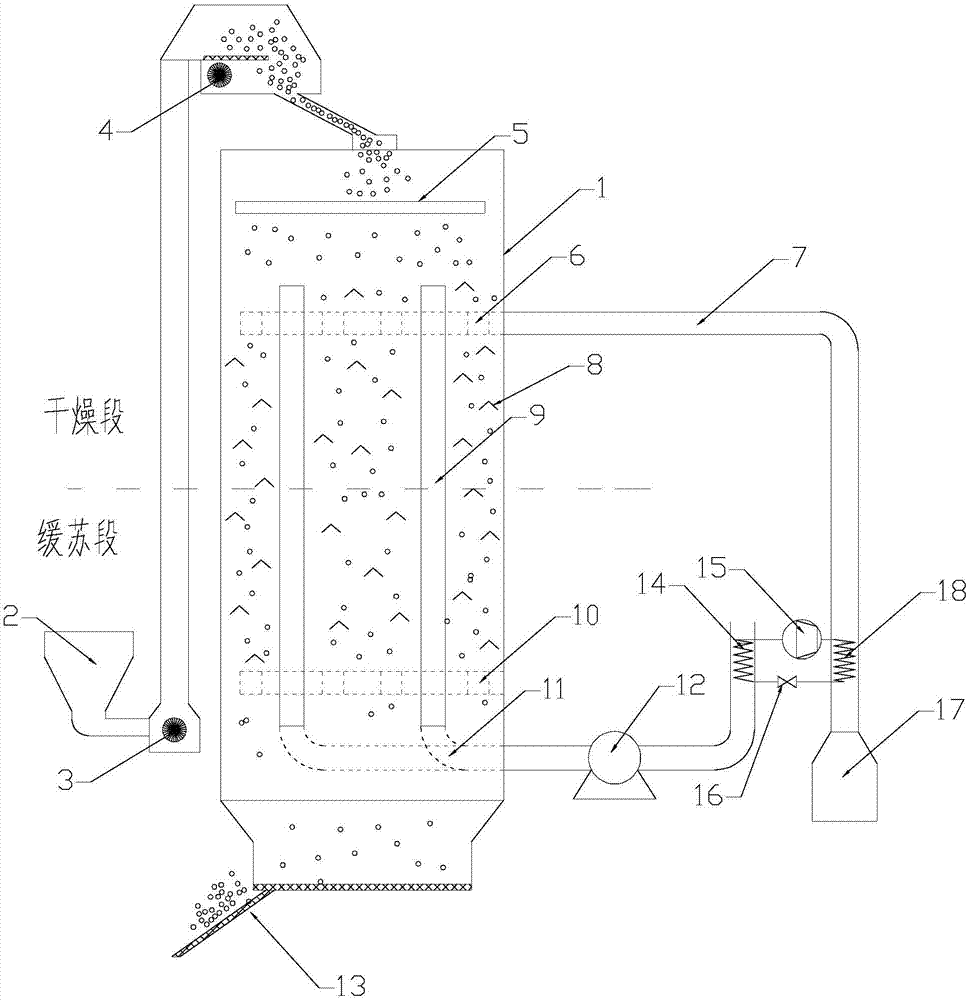

[0028] like figure 1 As shown, the grain drying device provided by the present invention includes a drying bin 1 for drying the grain; a feeding funnel 2 is also arranged on one side of the drying bin 1 for feeding grain, and the feeding funnel 2 is connected by a hoist 3 The conveyor belt 4 to the top of the drying bin 1 can send the grain into the drying bin 1 from the top; above the inside of the drying bin 1, a distributor 5 is arranged, and its function is to redistribute the grains that have fallen from the top Evenly, in a more loose manner into the body of the drying chamber 1. The distributor can be a gas redistributor or a vibrating screen redistributor.

[0029] In the main body of the drying bin 1, a side-flow hot air inlet is used, and the hot air convects heat from the side with the grains falling from the top. figure 1 Among them, the hot-blast inlet 6 is on the side, and the hot-blast outlet 10 is also on the side, and they are all indicated by dotted lines; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com