Material drying device and method

A drying device and material technology, applied in drying, drying machine, drying solid materials, etc., can solve the problems of poor pertinence of drying types, unbalanced energy distribution, uneven drying of materials, etc., and achieve the goal of seed drying Improved drying effect, higher efficiency, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

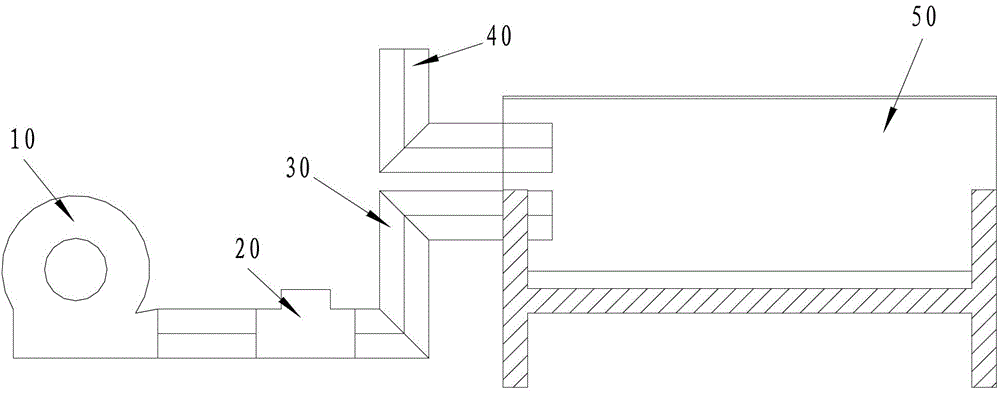

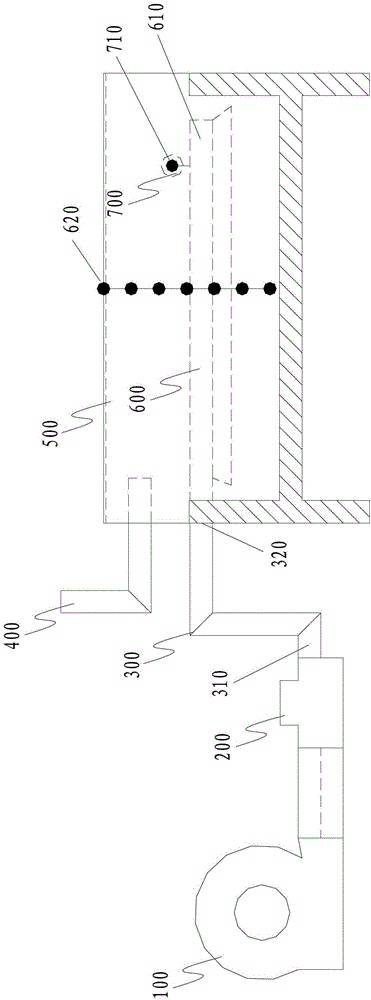

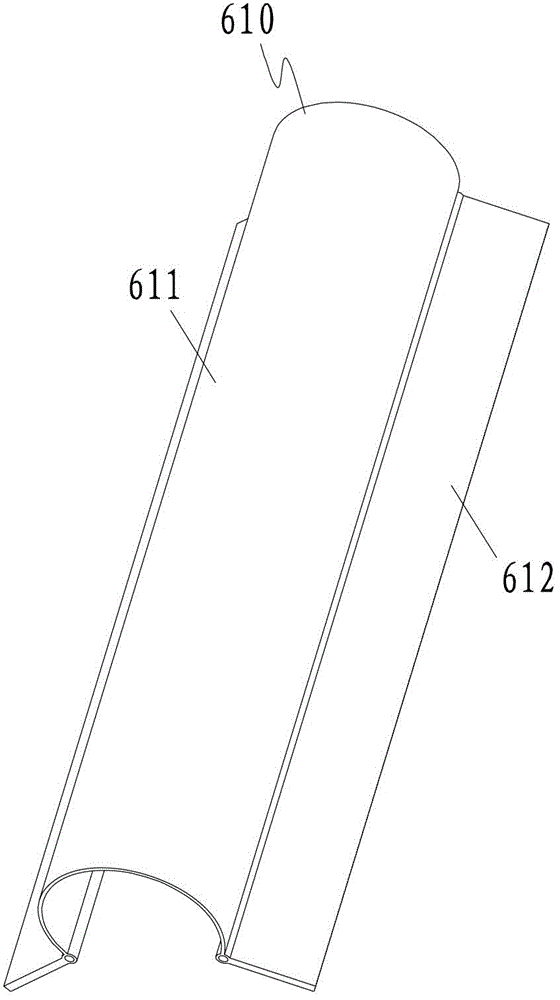

[0047] The material drying device and drying method based on the horizontal drum drying device of the present invention include an air direction and air volume adjustment unit and a temperature adjustment unit to ensure that the low-temperature hot air in the drum of the drying device is evenly distributed, and the air volume and air temperature are adaptively controlled so that the drying The dry unit works efficiently. The invention optimizes the utilization rate of drying wind energy by the drying device, reduces energy loss, and improves the efficiency of the drying device. When used for drying seeds, the drying effect of seeds is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com