Grain drying unit

A grain dryer and unit technology, applied in the direction of drying and saving seeds, etc., can solve the problems of low energy utilization rate, low degree of automation, weak processing capacity, etc., so as to achieve easy inspection and maintenance, reduce labor costs, and improve environmental protection. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

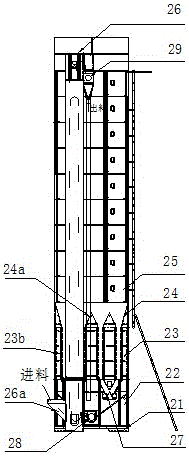

[0036] The present invention provides a grain drying unit, including a hot blast stove, a grain dryer, and a connecting pipe connecting the hot blast stove and the grain dryer. The following are specific embodiments of the invention.

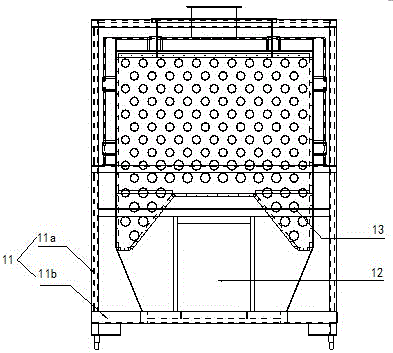

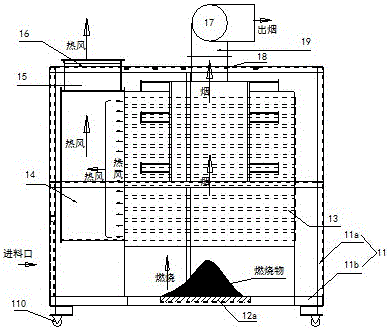

[0037] The hot blast stove 1 of the present embodiment is a biomass hot blast stove, utilizes grain waste as fuel, as attached figure 1 with 2 shown. The hot blast stove 1 comprises a body of furnace 11 surrounded by an outer frame 11a and a base 11b, the body of furnace 11 is provided with a furnace 12 below, a heating pipeline 13 above the furnace and a hot blast box 14 connected to the heating pipeline 13; The upper end of the box 14 is connected with a hot blast duct 15 leading to the outside of the furnace body 11, and the end of the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com