Controller special for two-section fire grain drier with multi-protection function

A grain dryer and multiple protection technology, applied in the sequence/logic controller program control, electrical program control and other directions, can solve the problems of asynchronous grain moisture loss, high grain burst rate and low reliability, etc. Scientific grain drying process, low grain burst rate, and the effect of avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

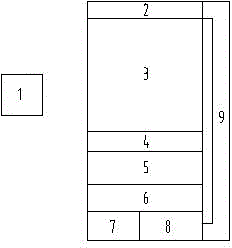

[0025] attached figure 1 It is a schematic diagram of the structure of the double-stage fire grain dryer, which includes a special controller for the double-stage fire grain dryer with multiple protections 1, the upper auger 2, the warehouse layer 3, the grain discharge wheel 4, the drying part layer 5, and the lower body layer 6 , the double-stage fire burner 7 for drying grain, the lower auger 8 and the hoist 9, the lower auger 8 and the hoist 9 are used to lift the grain in the heating and drying process or the grain fed into the feed port to the On the upper part of the dryer, the upper auger 2 sends the grain into the warehouse layer 3, and slows down the grain; the multi-way grain discharge wheel 4 disperses the grain at the bottom of the warehouse layer 3 to multiple locations through the rotation of the grain discharge wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com