Method for extending storage period of embryo rice

A technology for germ rice and storage period, applied in the field of fresh-keeping of agricultural products, can solve the problems of high burst rate and poor storage performance of germ rice, and achieve the effects of small burst rate, maintaining appearance and cooking characteristics, and ensuring the quality of rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Germ rice was placed on the conveyor belt at a conveying speed of 1 kg / s, preheated by hot air, treated with superheated steam, cooled by air step by step, and stored at room temperature (25±3°C, 65±3% RH). The specific heat treatment is as follows:

[0016] (1) Preheat the germ rice with hot air at 55°C, the air velocity is 3 m / s, the humidity is 30%, and the action time is 10 seconds; (2) Treat the germ rice with hot steam, the temperature is 200°C, The flow velocity is 2 m / s, and the action time is 10 seconds; (3) The germ rice is cooled by medium-temperature air, the air temperature is 45°C, the humidity is 40%, the flow velocity is 2 m / s, and the action time is 10 seconds; ( 4) Treat the germ rice grains with air, the air temperature is 20°C, the humidity is 20%, the flow rate is 3 m / s, and the action time is 10 seconds.

Embodiment 2

[0018] Germ rice was placed on the conveyor belt at a conveying speed of 1.5 kg / s, preheated by hot air, treated with superheated steam, cooled by air step by step, and stored at room temperature (25±3°C, 65±3% RH). The specific heat treatment is as follows:

[0019] (1) Preheat the germ rice with hot air at 60°C, the air velocity is 4 m / s, the humidity is 40%, and the action time is 15 seconds; (2) The germ rice is treated with hot steam, the temperature is 220°C, The flow velocity is 2.5 m / s, and the action time is 15 seconds; (3) The germ rice is cooled by medium-temperature air, the air temperature is 50°C, the humidity is 50%, the flow velocity is 3 m / s, and the action time is 20 seconds; ( 4) Treat the germ rice grains with air, the air temperature is 25°C, the humidity is 30%, the flow rate is 4 m / s, and the action time is 20 seconds.

Embodiment 3

[0021] Germ rice was placed on the conveyor belt at a conveying speed of 2 kg / s, preheated by hot air, treated with superheated steam, cooled by air step by step, and stored at room temperature (25±3°C, 65±3% RH). The specific heat treatment is as follows:

[0022] (1) Preheat the germ rice with hot air at 65°C, the air velocity is 5 m / s, the humidity is 60%, and the action time is 20 seconds; (2) Treat the germ rice with hot steam, the temperature is 250°C, The flow velocity is 3 m / s, and the action time is 20 seconds; (3) The germ rice is cooled by medium-temperature air, the air temperature is 55°C, the humidity is 60%, the flow velocity is 4 m / s, and the action time is 25 seconds; ( 4) Treat the germ rice grains with air, the air temperature is 30°C, the humidity is 40%, the flow rate is 5 m / s, and the action time is 30 seconds.

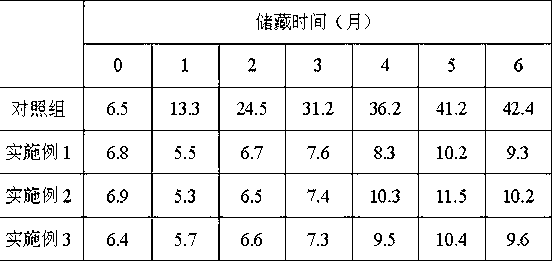

[0023] Effectiveness analysis:

[0024] (1) Effect of heat treatment on physical and chemical indicators of germ rice

[0025] Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com