Method for improving stewing performance and storage performance of unpolished rice

A storage and cooking technology, which is applied in the field of improving the cooking and storage properties of brown rice, can solve the problems of poor cooking performance and short storage period of brown rice, and achieve the goal of improving cooking performance, low bursting rate, and improving killing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Slowly add water by atomization until the water content of the brown rice is 22%, maintain a water addition rate of 0.6% / hour before the water content reaches 18%, and slowly increase the water addition rate to 1.0% / hour after the water content exceeds 18%; (2 ) Treat brown rice with microwaves, the microwave frequency is 2450±50MHz, the power is 350 watts, and the processing time is 35 seconds; (3) The microwave-treated brown rice is soaked for 30 minutes at 35°C and 80% humidity; (4) Under normal pressure, the brown rice is treated with superheated steam, the temperature of the superheated steam is 150° C., and the action time is 30 seconds. The treated brown rice was stored at room temperature (25±3°C, 65±3% RH) for 6 months.

Embodiment 2

[0015] (1) Slowly add water by atomization until the water content of brown rice is 21%, maintain the water addition rate of 0.6% / hour before the water content reaches 18%, and slowly increase the water addition rate to 0.9% / hour after the water content exceeds 18%; (2 ) Treat brown rice with microwaves, the microwave frequency is 2450±50MHz, the power is 400 watts, and the processing time is 30 seconds; (3) The microwave-treated brown rice is soaked for 25 minutes at 40°C and 85% humidity; (4) Under normal pressure, the brown rice is treated with superheated steam, the temperature of the superheated steam is 200° C., and the action time is 20 seconds. The treated brown rice was stored at room temperature (25±3°C, 65±3% RH) for 6 months.

Embodiment 3

[0017] (1) Slowly add water by atomization until the water content of brown rice is 20%, maintain the water addition rate of 0.6% / hour before the water content reaches 18%, and slowly increase the water addition rate to 0.8% / hour after the water content exceeds 18%; (2 ) Treat brown rice with microwaves, the microwave frequency is 2450±50MHz, the power is 450 watts, and the processing time is 25 seconds; (3) The brown rice treated by microwaves is slowed down for 20 minutes at 45°C and 90% humidity; (4) Under normal pressure, the brown rice is treated with superheated steam, the temperature of the superheated steam is 250° C., and the action time is 10 seconds. The treated brown rice was stored at room temperature (25±3°C, 65±3% RH) for 6 months.

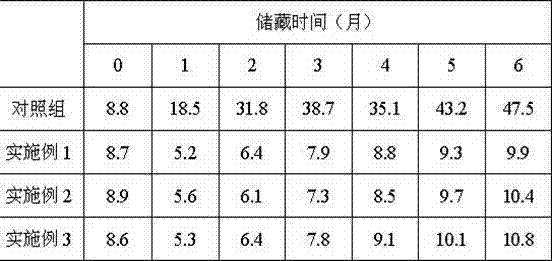

[0018] Effectiveness analysis:

[0019] (1) Physical and chemical indicators of brown rice

[0020] Moisture (%) Gelatinization degree (%) Vitamin B1 content (mg / 100g) Lipase activity (U / 100g) Lipoxygenase acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com