Grain elevator capable of automatically pouring grains

A hoist and grain technology, applied in the direction of conveyors, emptying containers, loading/unloading, etc., can solve the problems of increasing farmers' labor, not being stable enough, and reducing farmers' labor efficiency, so as to achieve device stability, improve work efficiency, and run convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

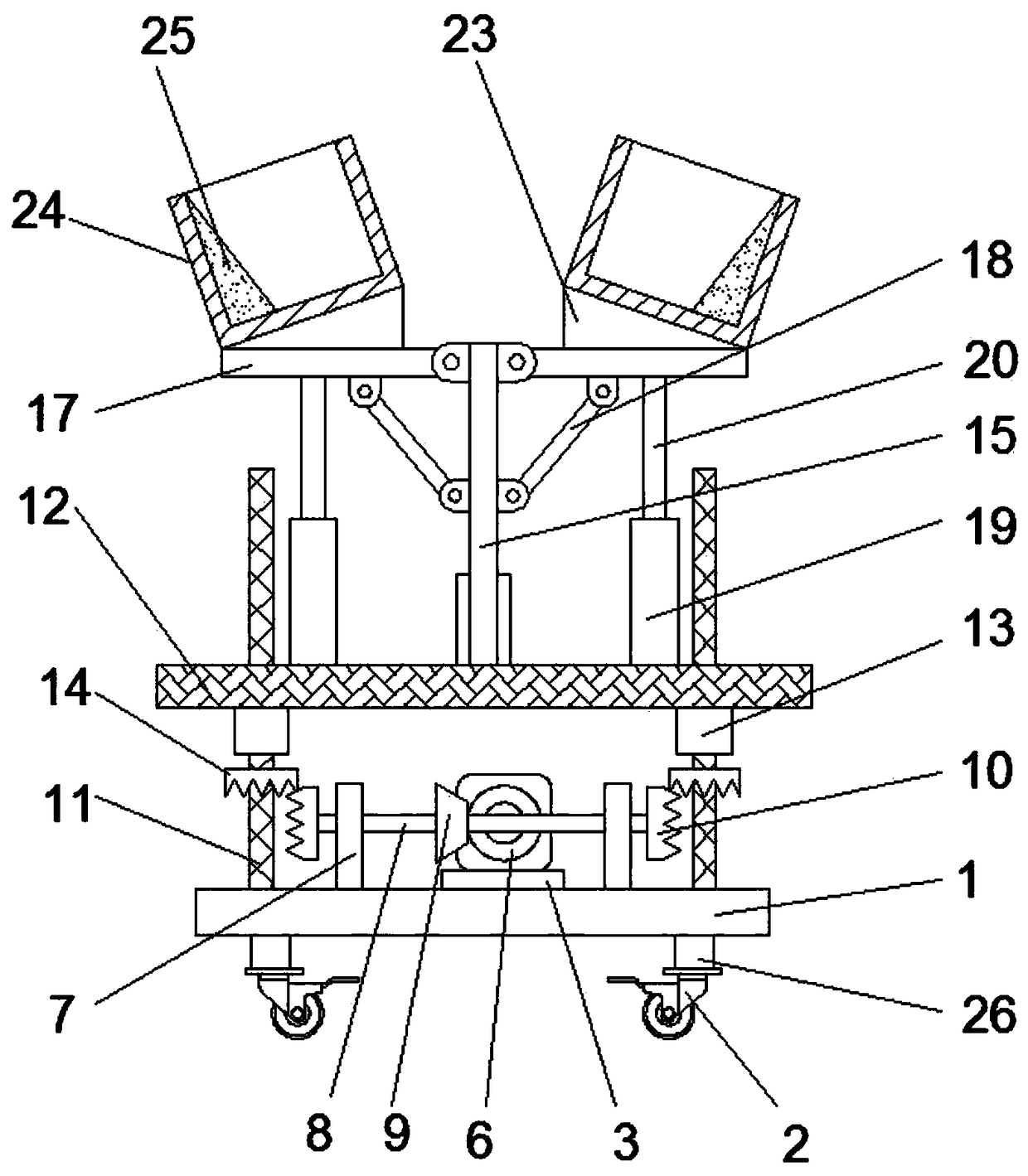

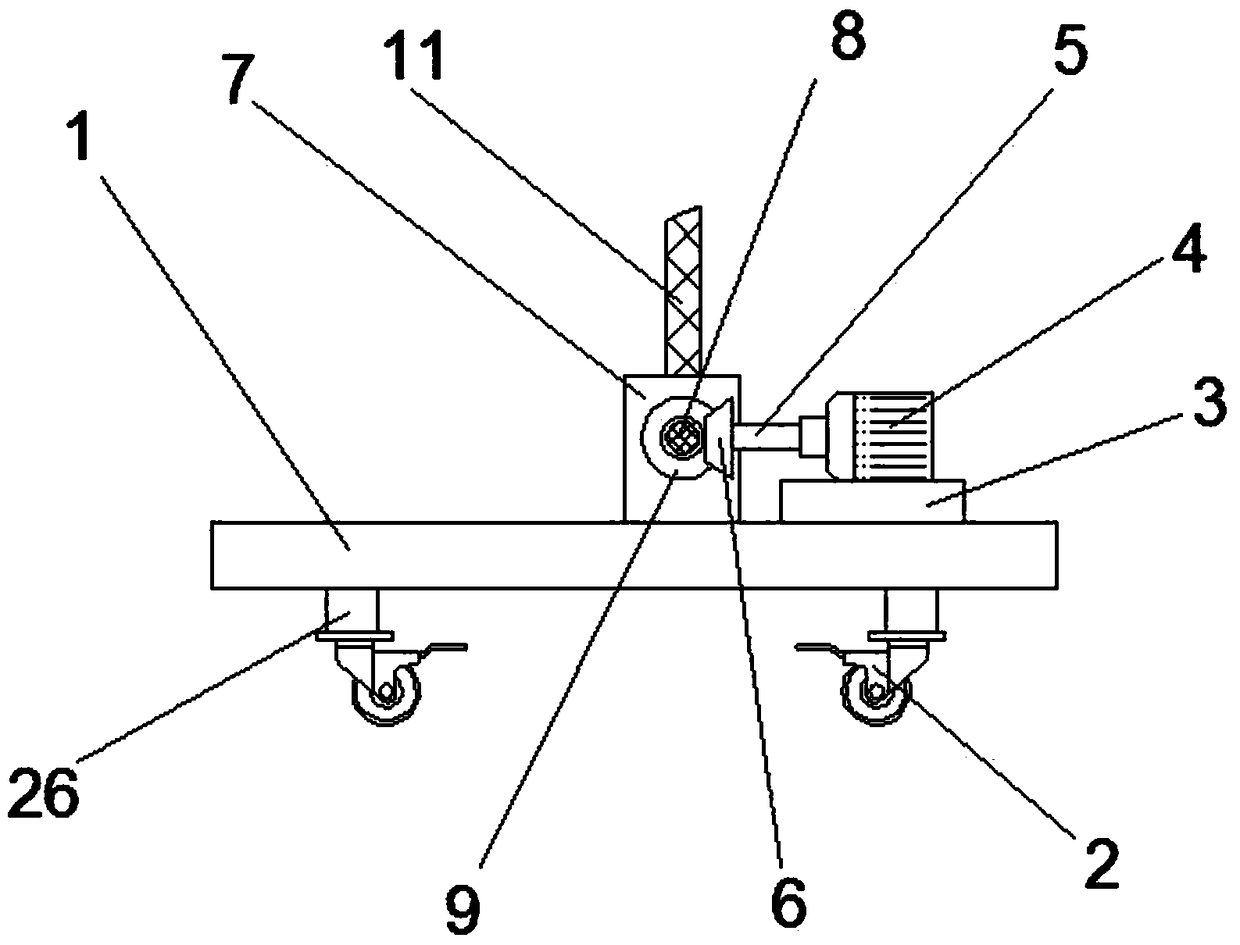

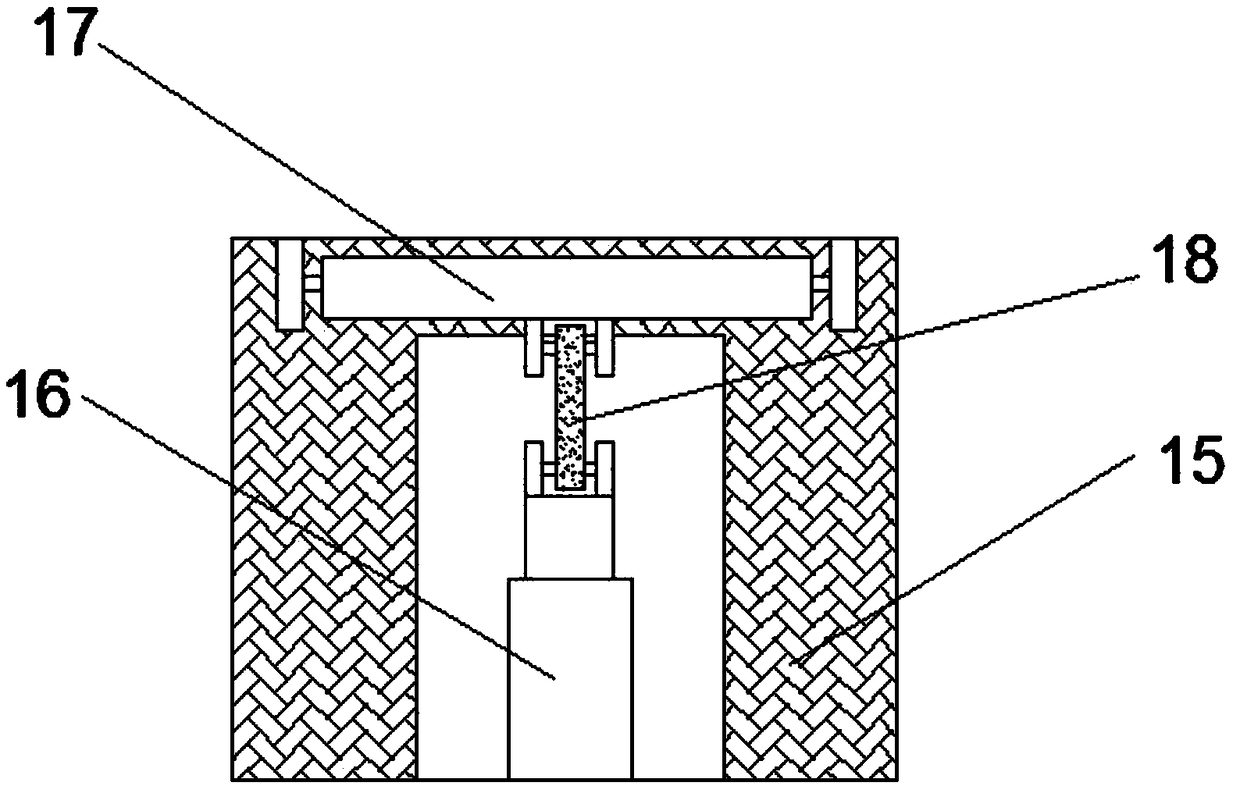

[0021] like Figure 1-Figure 4 As shown, a kind of grain hoist that can automatically pour grain that the present invention proposes comprises chassis 1, and chassis 1 lower end is provided with several universal wheels 2, and chassis 1 upper end middle part is provided with motor frame 3, and motor frame 3 upper end is provided with motor 4. The front end of the motor 4 is provided with a motor shaft 5, the front end of the motor shaft 5 is provided with a No. 1 bevel gear 6, the upper end of the chassis 1 is provided with a support plate 7 on both sides, the support plate 7 is provided with a rotating rod 8, and a rotating rod 8 The second bevel gear 9 is arranged in the middle, the third bevel gear 10 is arranged at the left and right ends of the rotating rod 8, the upper end of the chassis 1 is provided with a screw 11 on the outside of the support plate 7, and the middle of the screw 11 is provided with a moving plate 12 , the left and right sides of the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com