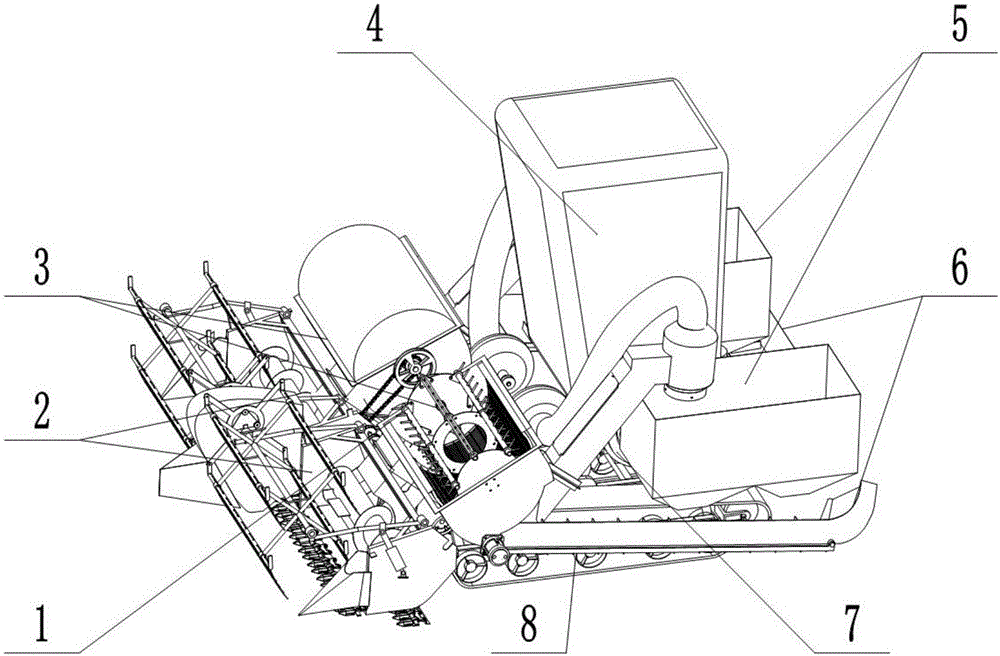

Dual-header dual-roller high-clearance rice harvesting machine

A high ground clearance and harvester technology, which is applied to the chassis of harvesters, cutters, and agricultural machinery, can solve the problems of unsuitable rice harvesting, low ground clearance of the chassis, and high rolling rate, so as to improve the passability of paddy fields , Reduce weight, reduce the effect of rolling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

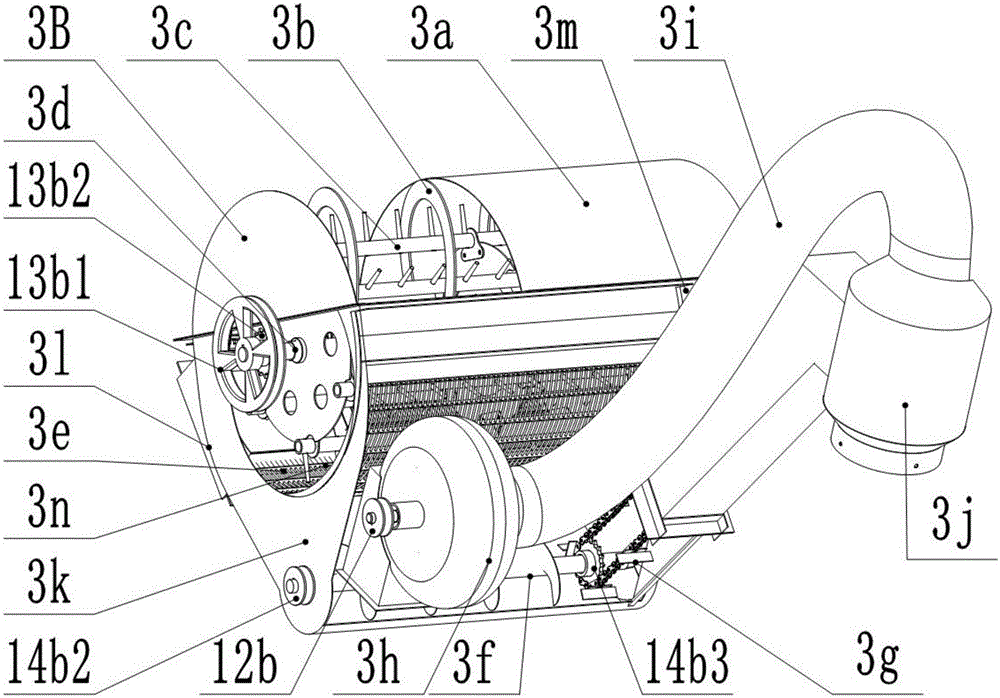

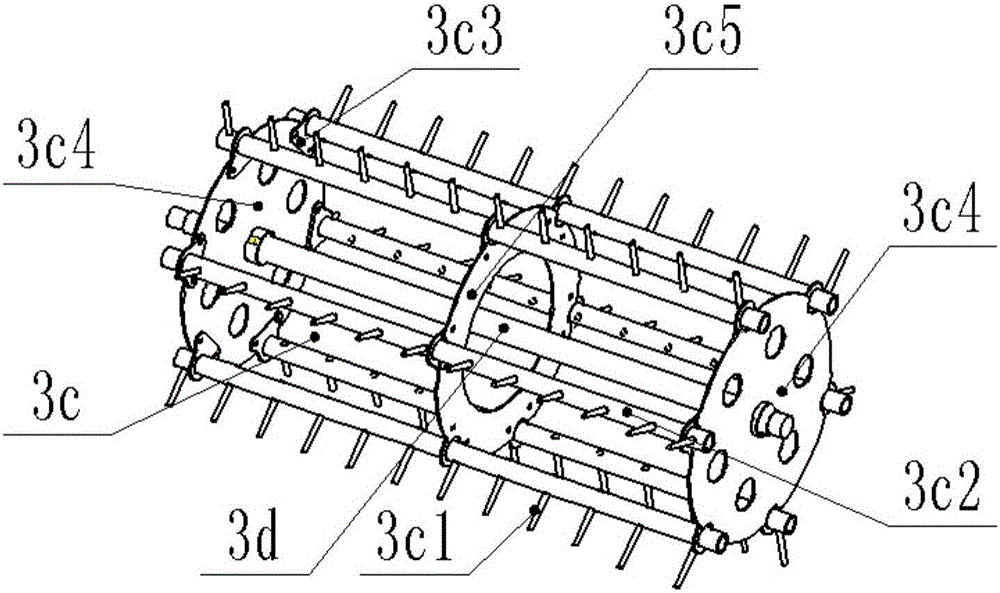

[0030] A double-harvesting harvesting platform double-drum high-clearance rice harvester, including a harvester body, the harvester body includes a walking power system with a hydraulic continuously variable transmission 1 and an engine 7, and a high-clearance chassis 8 with a walking device The double-drum cleaning assembly 3 is set on the high clearance chassis 8, and the front end of the double-drum cleaning assembly 3 is provided with a double-harvesting header 2, and the double-drum cleaning assembly 3 and the double-harvesting header 2 communicate with each other through the transmission device. The hydraulic continuously variable transmission 1 is connected to the engine 7, and two scraper-type straw conveying devices 6 are installed on the frame of the high-clearance chassis 8, and the two scraper-type straw conveying devices 6 are respectively located at the left and right grass outlets of the double-drum cleaning assembly 3 3m A cab and a console 4 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com