Novel seed lift conveyer of harvester

A technology for harvesters and elevators, which is applied to threshing equipment, agricultural machinery and implements, and applications. The effect of enhanced transportation capacity and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

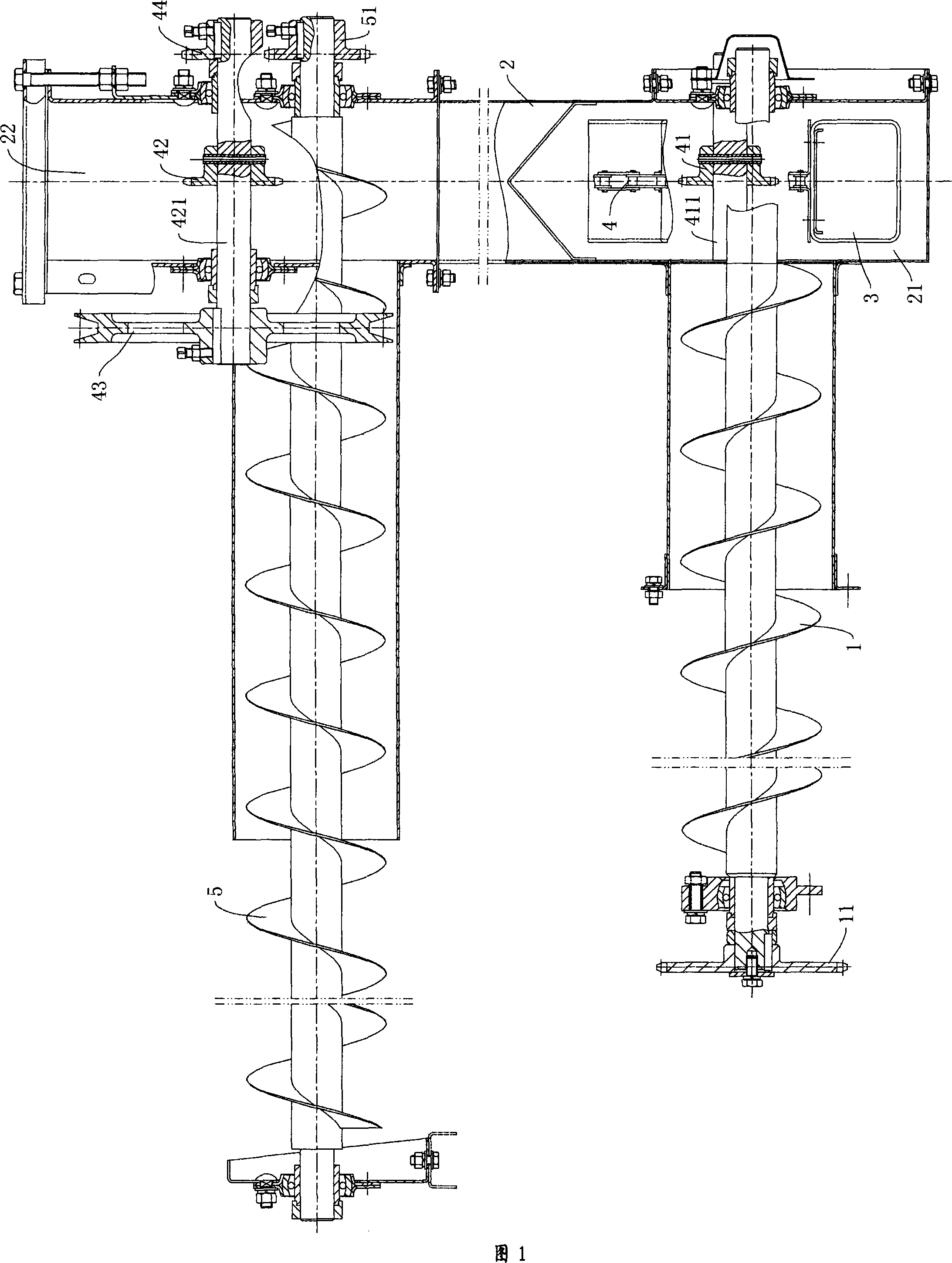

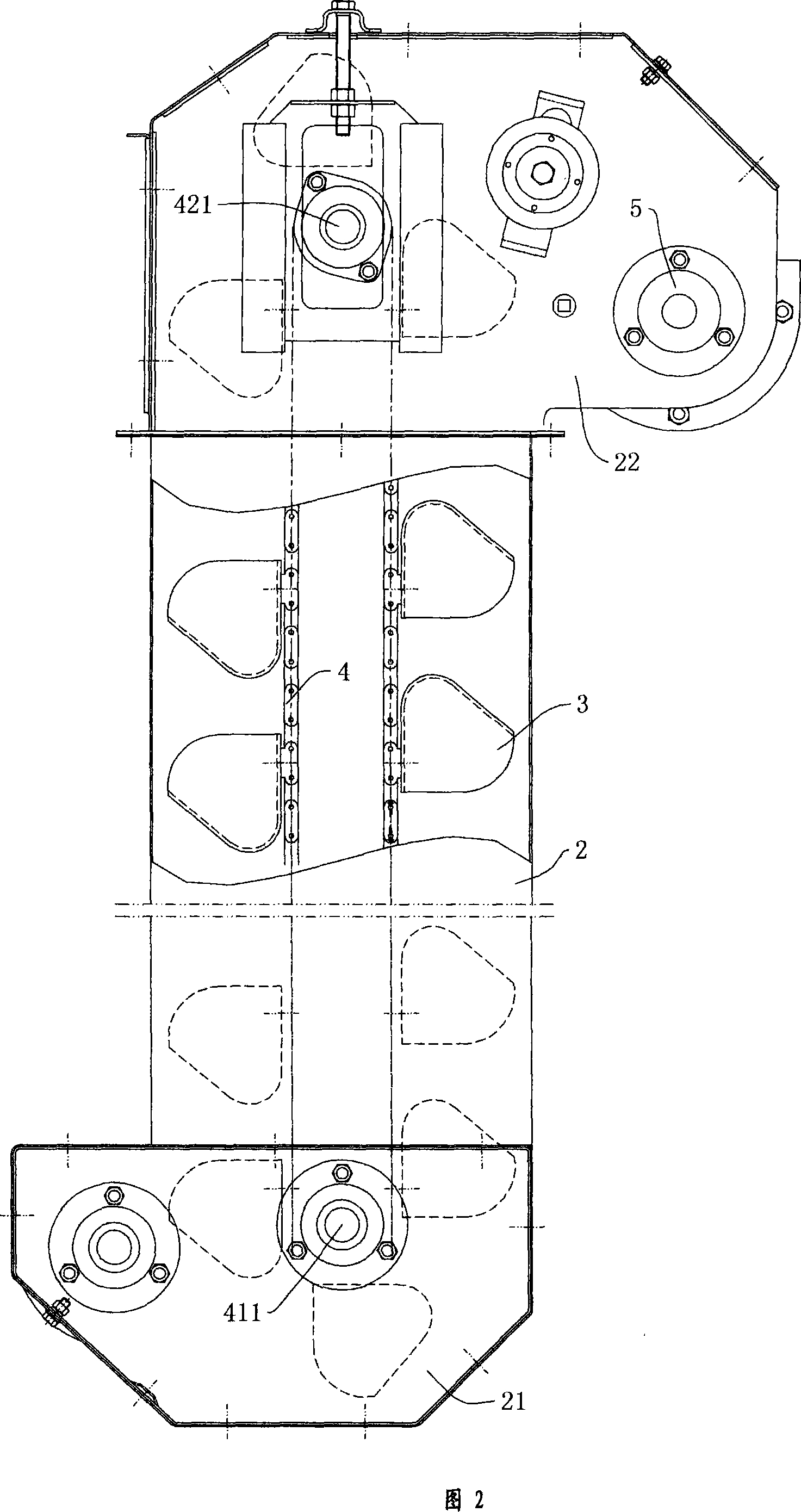

[0011] As shown in Fig. 1 and Fig. 2, the grain elevator of the novel harvester includes a cylindrical shell 2 vertically arranged on the harvester body, and the cylindrical shell 2 is preferably square with its cross section; The bottom of the cylindrical housing 2 is provided with a bottom grain storage chamber 21, and the top of the cylindrical housing 2 is provided with a top grain storage chamber 22, and in the cylindrical housing 2, the lifting shaft 421 and the lower lifting shaft 411 An ascending sprocket wheel 42 and a descending sprocket wheel 41 are respectively provided, and a closed annular elevating chain driven by the power unit of the harvester is provided between the ascending sprocket wheel 42 and the descending sprocket wheel 41. 4. A number of grain storage buckets 3 are arranged in sequence on the lifting chain 4, and a tensioning device for the lifting chain 4 can be arranged on the cylindrical housing 2, so as to facilitate the safety and reliability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com