Grain elevator

A grain suction box and grain box technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of long time consumption, achieve the effect of convenient assembly and disassembly, good versatility, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

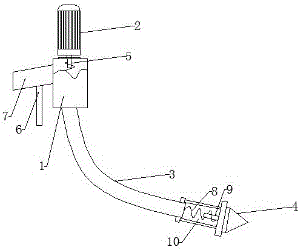

[0012] A grain suction machine, comprising a grain suction box 1, a motor 2, a grain suction hose 3, and a drill bit 4, the motor 2 is located directly above the grain suction box 1, and the output shaft 5 of the motor 2 runs through the grain suction box 1 The top wall of the grain suction box 1 is provided with a grain outlet, the grain outlet communicates with one end of the grain suction hose 3, and the grain outlet is provided with a downwardly inclined grain outlet tube 7 , the discharge cylinder 7 is provided with a fixed column extending vertically downwards, the grain suction hose 3 is penetrated with a spring 8, one end of the spring 8 is connected to the output shaft 5, and the other end is sleeved on the drill bit 4 On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com