Mass flow grain monitor and method

a grain monitor and mass flow technology, applied in the field of grain monitors, can solve the problems of introducing errors into the output data, affecting the quality of grain, and affecting the quality of grain, and achieve the effect of simple yet effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is susceptible of embodiment in many different forms. While the drawings illustrate and the specification describes certain preferred embodiments of the invention, it is to be understood that such disclosure is by way of example only. There is no intent to limit the principles of the present invention to the particular disclosed embodiments.

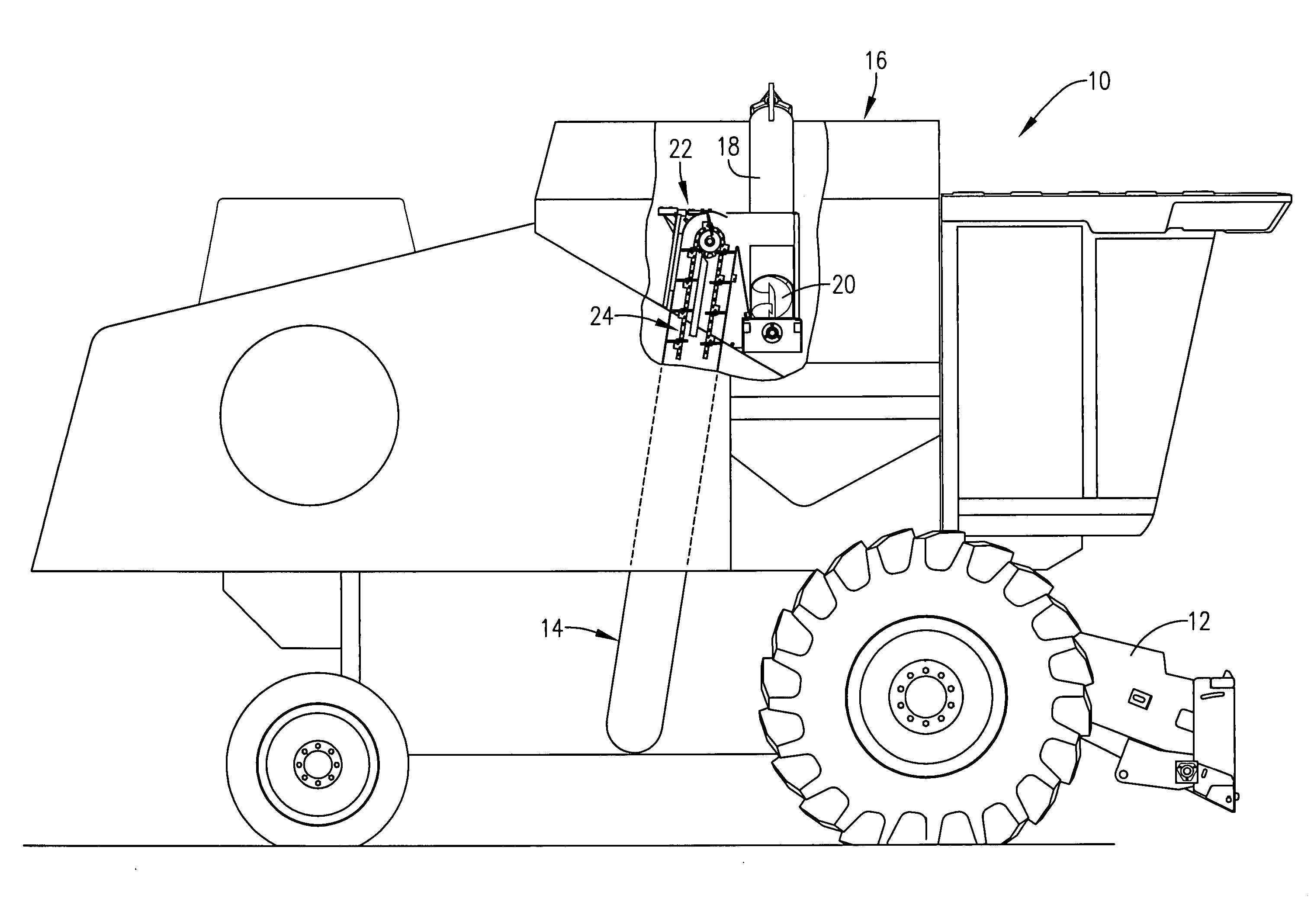

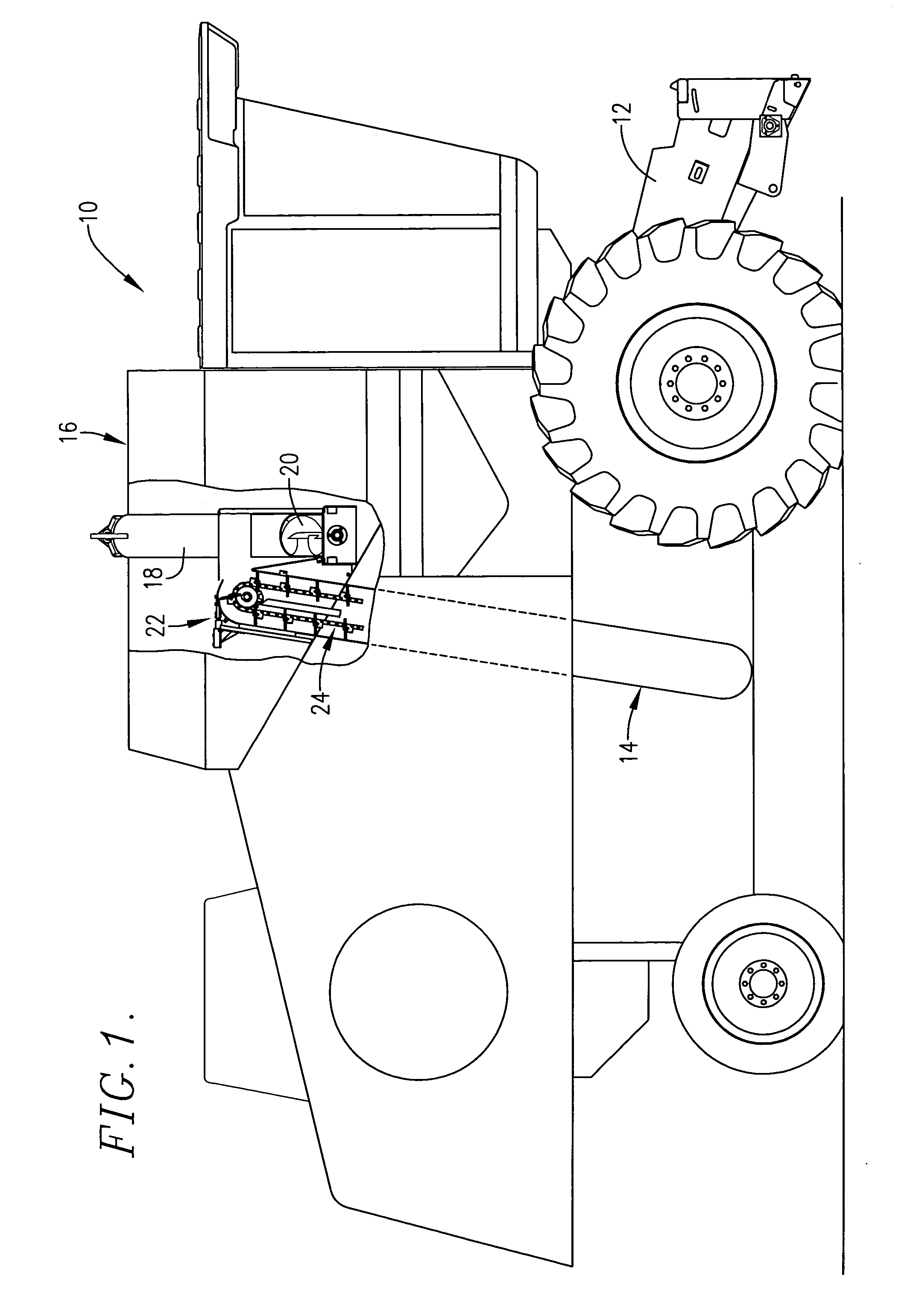

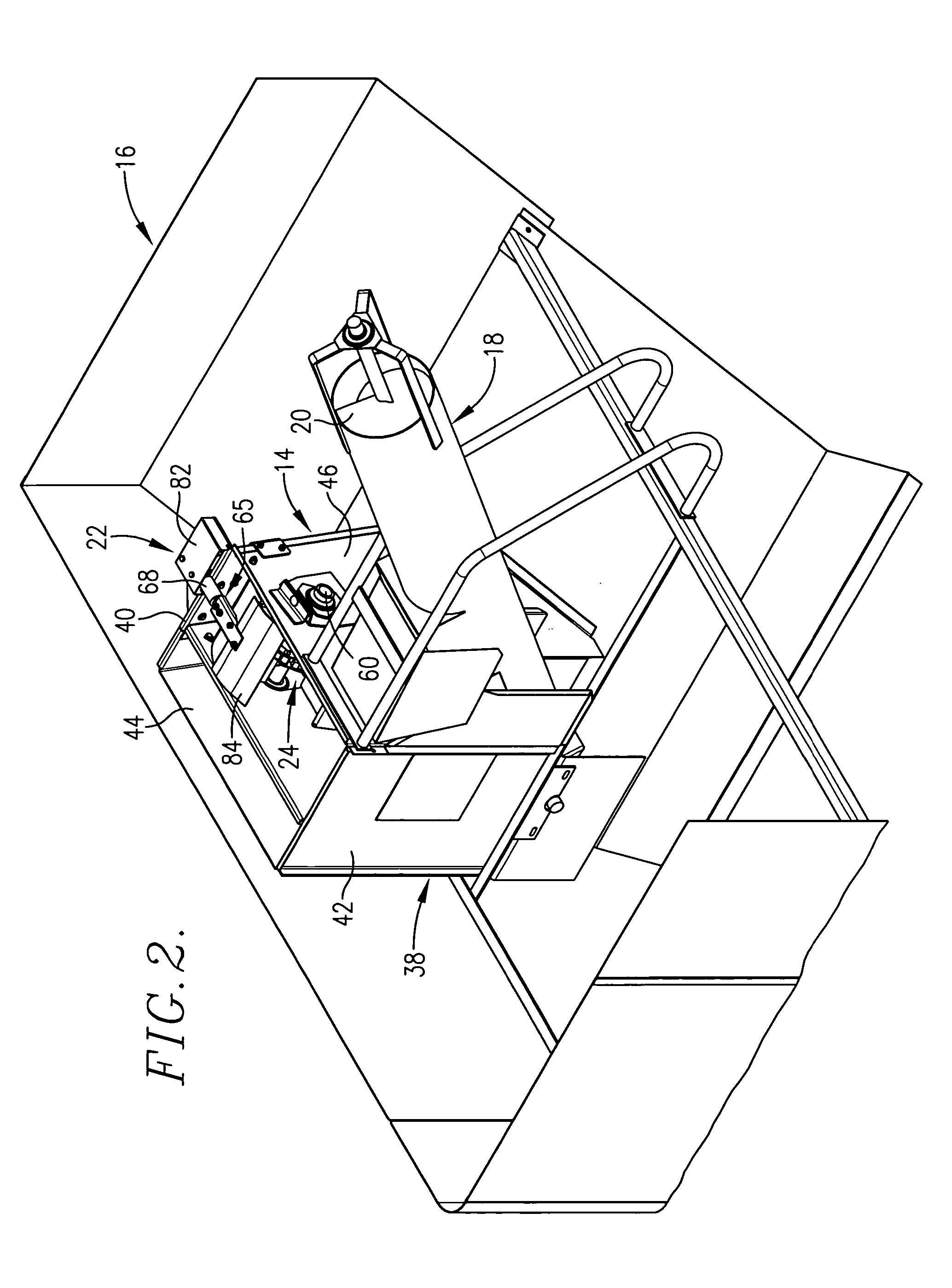

[0017] The combine harvester 10 in FIG. 1 is illustrated without a harvesting header attached to the lower front end of feeder housing 12. During harvesting operations, however, a header of suitable design is supported at the front end feeder housing 12 and directs harvested materials into the same for subsequent processing by internal threshing and cleaning mechanism of the harvester. Generally speaking, waste products such as straw, stalks, leaves, husks, hulls and chaff exit the machine through the rear thereof while clean grain is directed to a clean grain elevator assembly 14 near the bottom of the machine and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com