Silicon wafer fine polishing combined solution capable of inhibiting particle deposition and preparation method thereof

A combined liquid and fine polishing technology, applied in the field of chemical mechanical polishing (CMP), can solve problems such as removal, and achieve the effects of reducing residues, easily obtaining raw materials, and reducing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

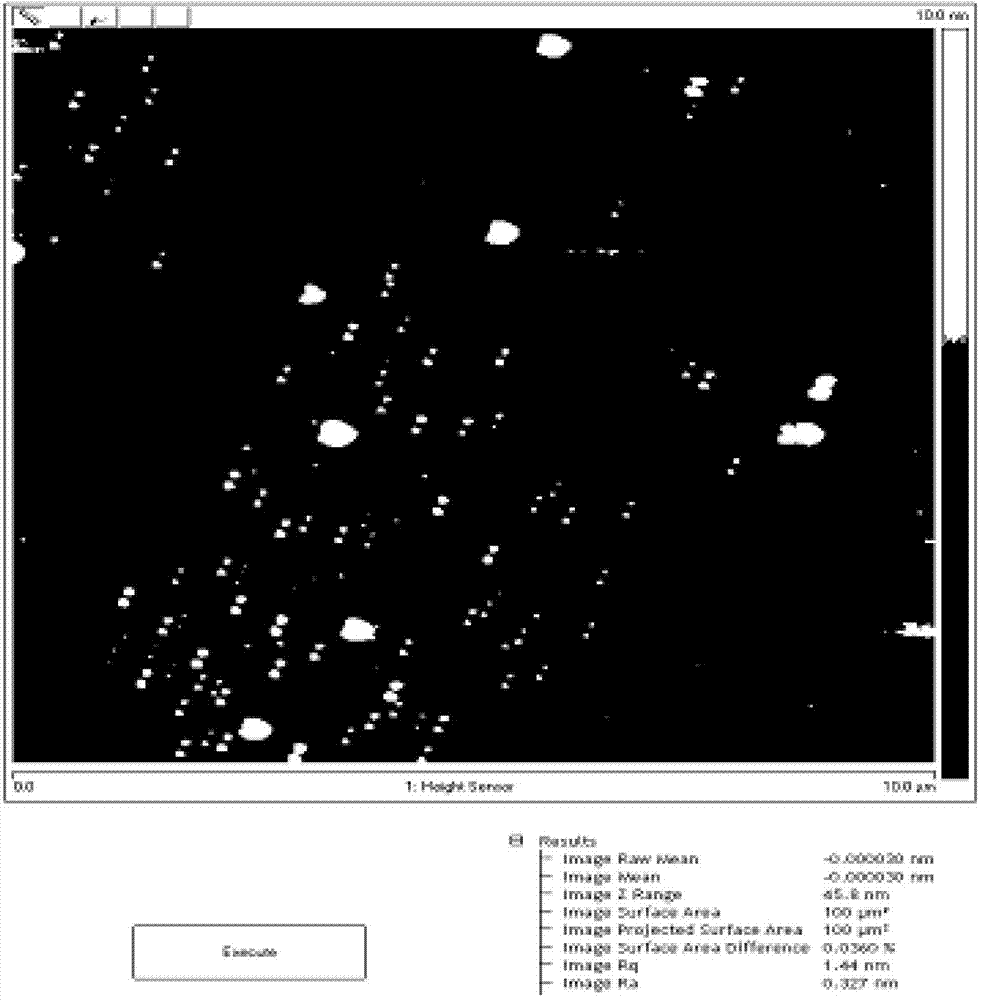

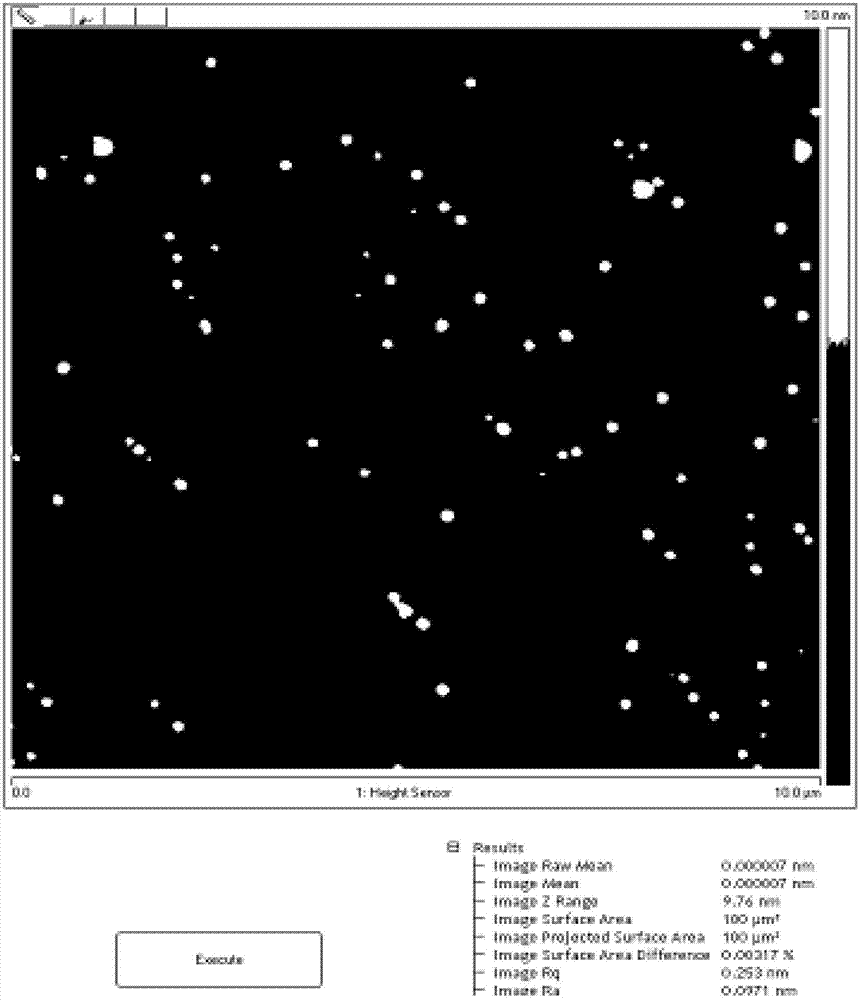

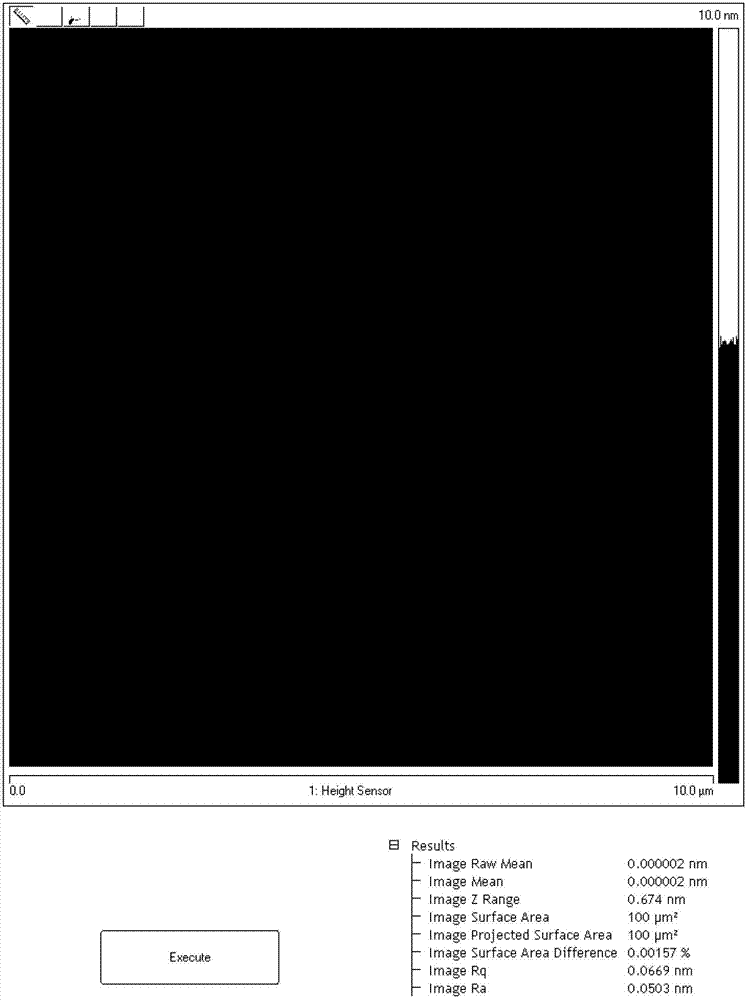

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below by specific examples, which certainly should not be construed as limiting the scope of the present invention in any case.

[0033] A silicon wafer fine polishing composition capable of inhibiting particle deposition of the present invention, comprising colloidal silicon dioxide / water-soluble polymer composite abrasive grains, hydroxyl and / or amine-containing surface protective agents, alkaline compounds, and surfactants and deionized water; the pH value of the fine polishing combination liquid is 8-12. Among them, the weight percent content of colloidal silica / water-soluble polymer composite abrasive grains is 2-13wt%, the weight percent content of hydroxyl and / or amine-containing surface protection agent is 0.002-0.5wt%, the basic compound The weight percentage content is 0.5-4 wt%, the weight percentage content of the surfactant is 0.002-0.5 wt%, and the balance is deionized water. Colloidal silica / water-soluble ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com