Preparation technology of self-suspension coated support material

A supporting material and preparation technology, which is applied in the direction of drilling composition, production fluid, wellbore/well parts, etc., can solve the problems of increased construction cost, increased production cost, and high cost, so as to reduce construction cost and improve work efficiency. Efficiency and reduced equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

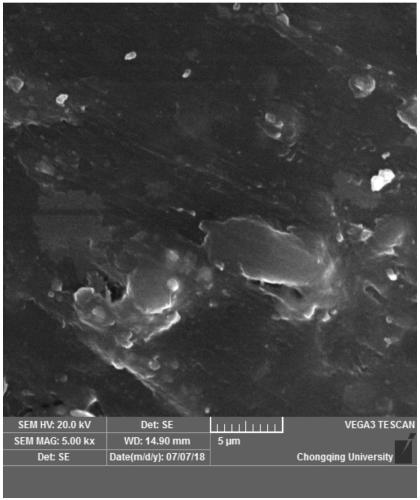

Image

Examples

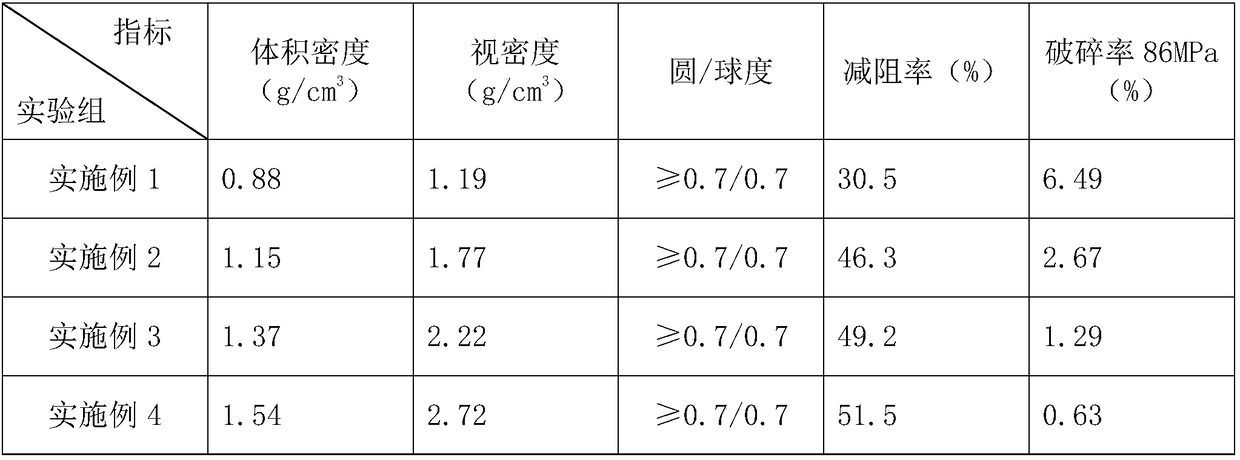

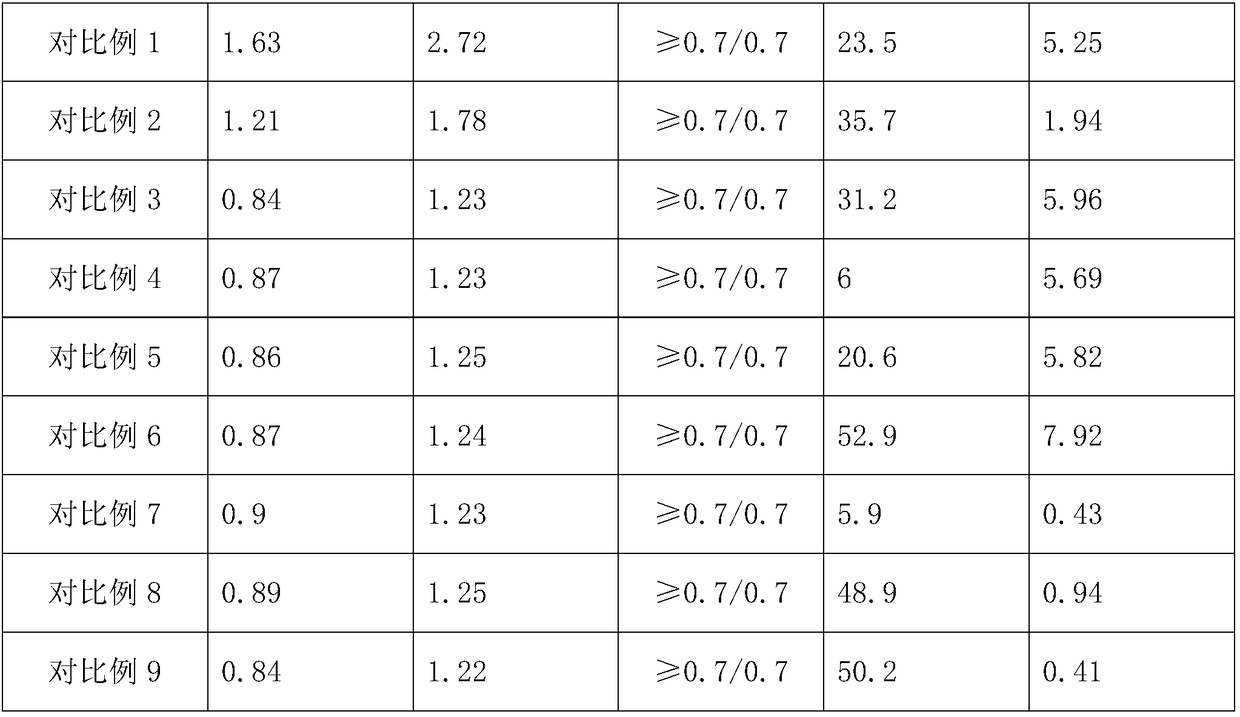

Embodiment 1

[0039] Take the apparent density as 1.05g / cm 3 100 parts of ceramsite with a particle size of 20 / 40, heated to 180-190°C, poured the heated ceramsite into a bowl-shaped mixing casserole, then added 2 parts of epoxy resin and stirred; the temperature dropped to 150-160°C, added 0.2 parts of modified aromatic amine curing agent (T31) and stir; the temperature drops to 140-150 ° C, then add 0.3 parts of drag reducer and mix; the temperature drops to 80-90 ° C, add 2 parts of propylene glycol and 0.02 parts of dilaurel Stir with dibutyltin acid; when the temperature drops to 70-80°C, add 0.2 parts of ethylenediamine and stir; when the temperature drops to 60-70°C, add 0.8 parts of toluene diisocyanate and stir; Resist mixed; the temperature dropped to 40-50 ℃ out of the pot. Epoxy resin and modified aromatic amine curing agent form an inner resin film, and the inner resin film is an epoxy resin film; glycerol, dibutyltin dilaurate, diethylenetriamine and toluene diisocyanate form...

Embodiment 2

[0041] Take the apparent density as 1.65g / cm 3 100 parts of ceramsite with a particle size of 30 / 50, heated to 220-230°C, poured the heated ceramsite into a bowl-shaped mixing casserole, then added 3 parts of phenolic resin and stirred; when the temperature dropped to 190-200°C, added 0.6 1 part of hexamethylenetetramine and stir; the temperature drops to 180-190°C, and then 0.6 parts of drag reducer are added and mixed; When the temperature drops to 100-110°C, add 0.2 parts of triethylamine and stir; when the temperature drops to 90-100°C, add 1 part of methylene diphenyl diisocyanate and stir; when the temperature drops to 70-80°C, add 0.6 parts of drag reduction The agent is mixed; the temperature is lowered to 60-70 ℃ and the pot is taken out.

Embodiment 3

[0043] Take the apparent density as 2.05g / cm 3 100 parts of ceramsite with a particle size of 40 / 70, heated to 80-90°C, poured the heated ceramsite into a bowl-shaped mixing casserole, then added 2 parts of ethylene glycol and 0.02 parts of tributyltin and stirred; the temperature dropped to 70 -80°C, add 0.6 parts of isophorone diisocyanate and stir; when the temperature drops to 60-70°C, add 0.7 parts of drag reducer and mix; when the temperature drops to 50-60°C, add 4 parts of glycerol and 0.02 parts of Stir with lead isooctanoate; when the temperature drops to 40-50°C, add 0.2 parts of triethylamine and stir; when the temperature drops to 35-45°C, add 1 part of methylene diphenyl diisocyanate and stir; when the temperature drops to 30-40°C, Then add 0.8 parts of drag reducer and mix; the temperature is lowered to 30-35°C and taken out of the pot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com