High-binding-force graphite film metal composite material and preparation method thereof

A metal composite material, graphite film technology, applied in metal layer products, chemical instruments and methods, electronic equipment and other directions, can solve the problem that the operation process is not easy to control, the composite layer material preparation method is complicated, and the graphite film and the metal layer are insufficient. and other problems, to achieve the effects of excellent electromagnetic shielding performance, favorable adhesion, low surface flatness and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

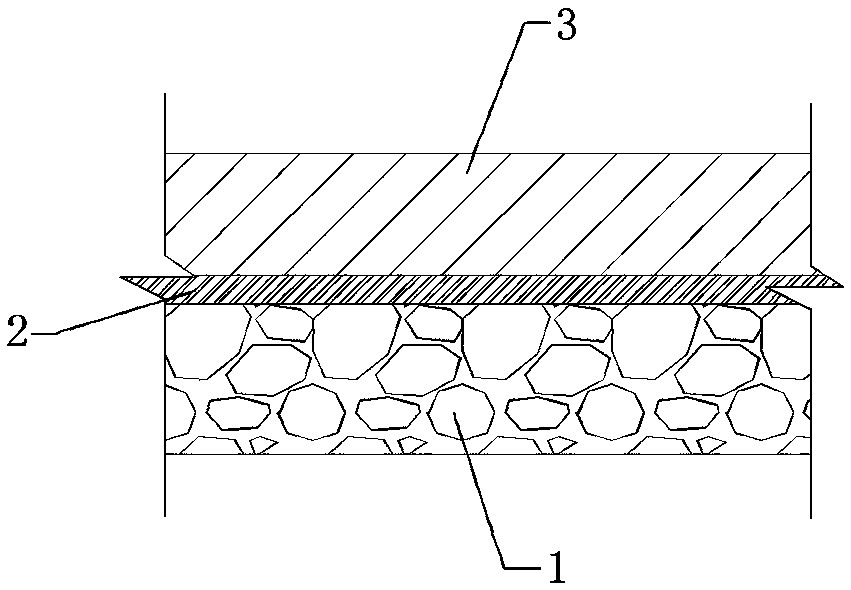

[0039] The temperature of the polyimide film is gradually raised to 1100°C-1400°C at -0.1MPa to obtain a carbonized film; then in an inert gas environment, the temperature of the carbonized film is gradually raised to 2600°C-3000°C to obtain a graphite film, and the prepared graphite The thickness of the film is 70 μm; the copper powder is evenly sprayed on the graphite film, the particle size of the copper powder is 10-30nm; and placed in a high-temperature furnace, at -0.2Pa, the temperature is raised to 1100 °C at 10 °C / min and kept 5min, then gradually cooled to room temperature at a rate of 0.6°C / min; take it out and carry out calendering treatment to obtain a graphite film with a copper metal transition layer, the thickness of the metal transition layer is 20nm; the surface of the metal transition layer is subjected to pickling and activation treatment, Then it is immersed in the electroless copper plating solution, and it is immersed for 30min at room temperature; after ...

preparation Embodiment 2

[0041] The temperature of the polyimide film is gradually raised to 1100°C-1400°C at -0.1MPa to obtain a carbonized film; then in an inert gas environment, the temperature of the carbonized film is gradually raised to 2600°C-3000°C to obtain a graphite film, and the prepared graphite The thickness of the film is 20μm; after mixing the copper powder and silver powder with a mass ratio of 4:1, evenly spray on the graphite film, the average particle size of the copper powder and silver powder is 50nm; and put it in a high temperature furnace, at -0.3Pa temperature at 8.5°C / min to 1050°C, hold for 5min, and then gradually cool to room temperature at a rate of 0.8°C / min; take it out and perform calendering treatment to obtain a graphite film with a copper-silver transition layer, the thickness of the metal transition layer is 50nm; after pickling and activating the surface of the metal transition layer, electroplating a silver metal layer on the surface; and coating the metal antiox...

preparation Embodiment 3

[0043]The temperature of the polyimide film is gradually raised to 1100°C-1400°C at -0.1MPa to obtain a carbonized film; then in an inert gas environment, the temperature of the carbonized film is gradually raised to 2600°C-3000°C to obtain a graphite film, and the prepared graphite The thickness of the film is 30 μm; after mixing the copper powder and silver powder at a mass ratio of 1:1, evenly spray on the graphite film, the average particle size of the copper powder and silver powder is 70nm; , heat up to 1000°C at 5°C / min, keep for 20min, and then gradually cool to room temperature at a rate of 0.7°C / min; take it out and carry out calendering treatment to obtain a graphite film with a copper-silver transition layer, the thickness of the metal transition layer is 30nm; after the surface of the metal transition layer is pickled and activated, a silver metal layer is plated on the surface by vacuum plating; and a metal antioxidant is coated on the surface of the metal layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com