Organic compost capable of repairing soil and preparation method of organic compost

A technology for organic composting and soil remediation, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems of small internal porosity, affecting the degree of compost decomposting, and taking a long time to naturally heat up. The effect of reducing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

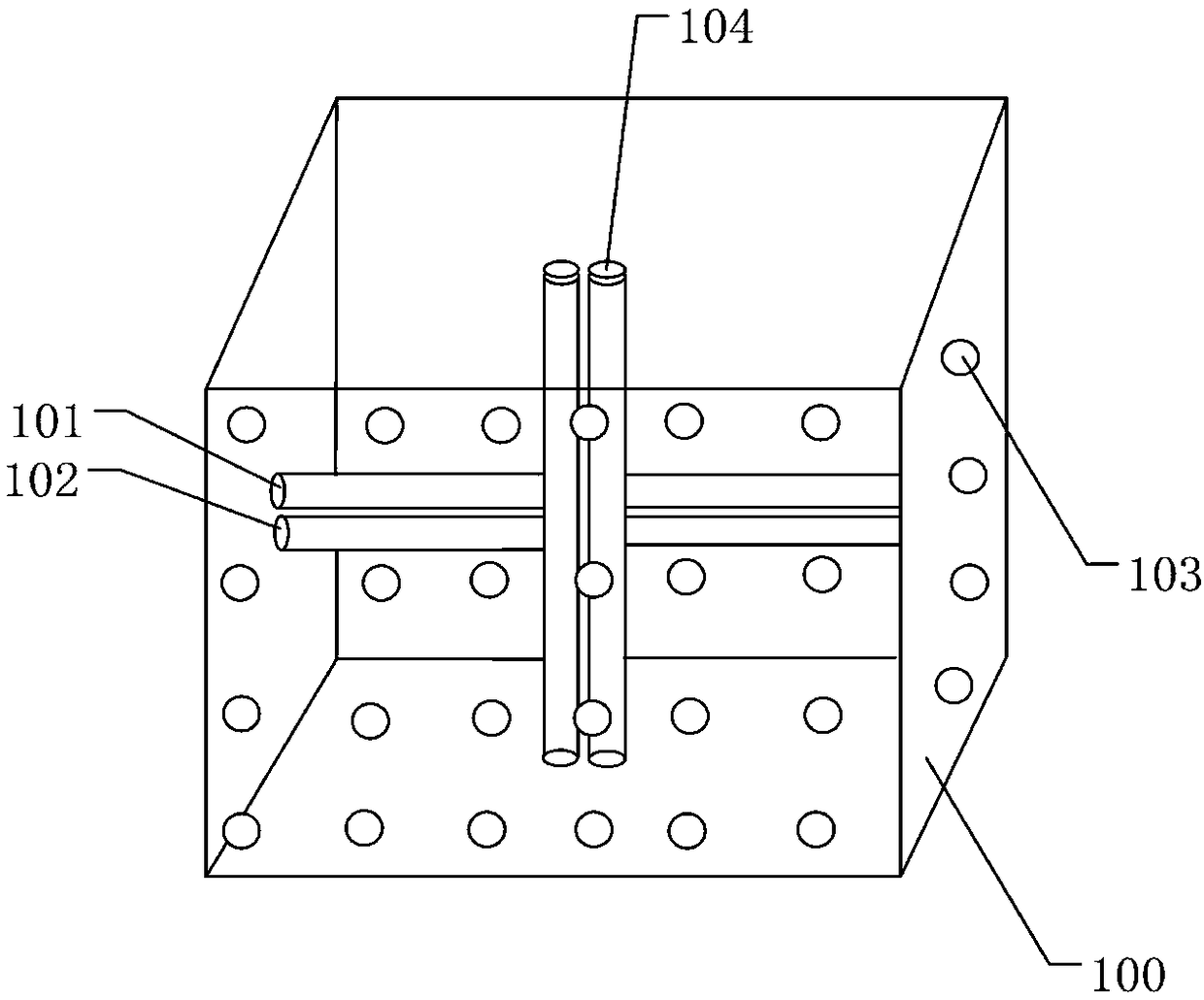

Image

Examples

preparation example Construction

[0063] The present invention also provides a kind of preparation method of the organic compost of described repairable soil, wherein, comprise the following steps:

[0064] Step 1: Treatment of the organic base material: taking the organic raw material and pulverizing it and drying it to a water content below 5%, weighing and mixing according to the components of the organic raw material;

[0065] Step 2: Preparation of microbial bacterial liquid: Weigh the bacterial agent contained in the microbial bacterial liquid and mix, then mix evenly with 10-15 times the volume of glucose water or brown sugar water, and seal and ferment for 3-5 days to obtain the microbial bacterial liquid liquid;

[0066] Step 3: Preparation of the bulky material: Weigh the dry chicken manure and Tenebrio molitor manure according to the composition of the bulky material, crush and sieve the dry chicken manure to 60-100 meshes and mix evenly with the Tenebrio molitor manure to obtain the the bulky mate...

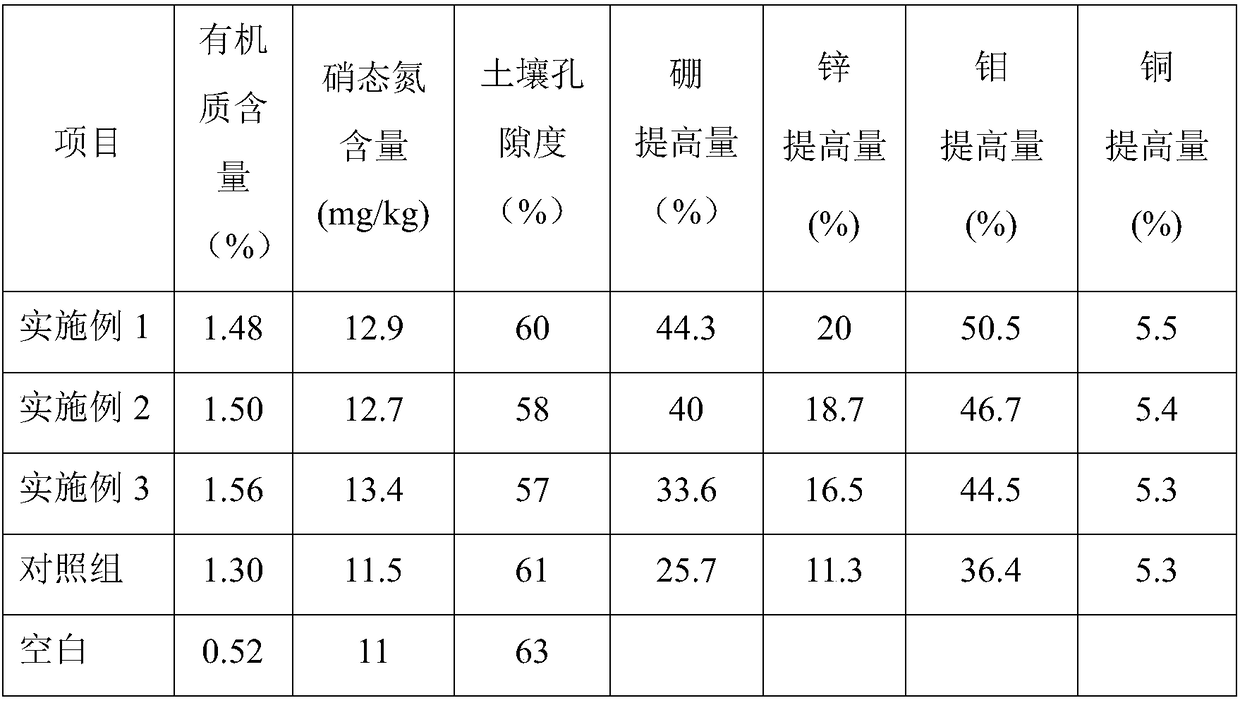

Embodiment 1

[0085] Step 1: Treatment of organic base materials: take 20 parts of plant branches, 10 parts of plant fallen leaves, 5 parts of seed shells, 10 parts of animal manure and 5 parts of animal bones that have been crushed and dried to a water content below 5% and mix evenly to obtain the obtained the organic material;

[0086] Step 2: Preparation of microbial bacterial liquid: Weigh 2 parts of Bacillus subtilis, 2 parts of Thermostable Bacillus, 0.5 part of mycorrhizal fungus, 1 part of yeast, 0.5 part of Terrestrial mold and 1 part of Bacillus lateralis and mix them with 12 times the volume of brown sugar water (mixed with brown sugar and water in a mass ratio of 1:2) was mixed evenly, and sealed and fermented at 30° C. for 4 days to obtain the microbial bacterial liquid;

[0087] Step 3: Preparation of bulky material: Weigh 3 parts of dried chicken manure and 2 parts of Tenebrio molitor manure, crush and sieve the dried chicken manure to 80 meshes and mix evenly with Tenebrio m...

Embodiment 2

[0100] Step 1: Treatment of organic base materials: Take 30 parts of plant branches, 18 parts of plant fallen leaves, 10 parts of seed shells, 15 parts of animal manure and 10 parts of animal bones that have been crushed and dried to a water content of less than 5% and mix evenly to obtain the described organic material;

[0101] Step 2: Preparation of microbial bacterial liquid: Weigh 5 parts of Bacillus subtilis, 5 parts of Thermostable Bacillus, 1.5 parts of mycorrhizal fungus, 3 parts of yeast, 1 part of Terrestrial mold, 3 parts of Bacillus lateralis and mix them with 12 times the volume of brown sugar water (mixed with brown sugar and water in a mass ratio of 1:2) was mixed evenly, and sealed and fermented at 30° C. for 4 days to obtain the microbial bacterial liquid;

[0102] Step 3: Preparation of bulky material: Weigh 5 parts of dried chicken manure and 4 parts of Tenebrio molitor manure, crush and sieve the dried chicken manure to 80 meshes and mix evenly with Tenebr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com